Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent pharmaceuticals, with robust containment measures that meet strict Operational Exposure Band requirements, maintaining product integrity and minimizing cross-contamination risks.

Contains and Packages High-Potency Pharmaceuticals

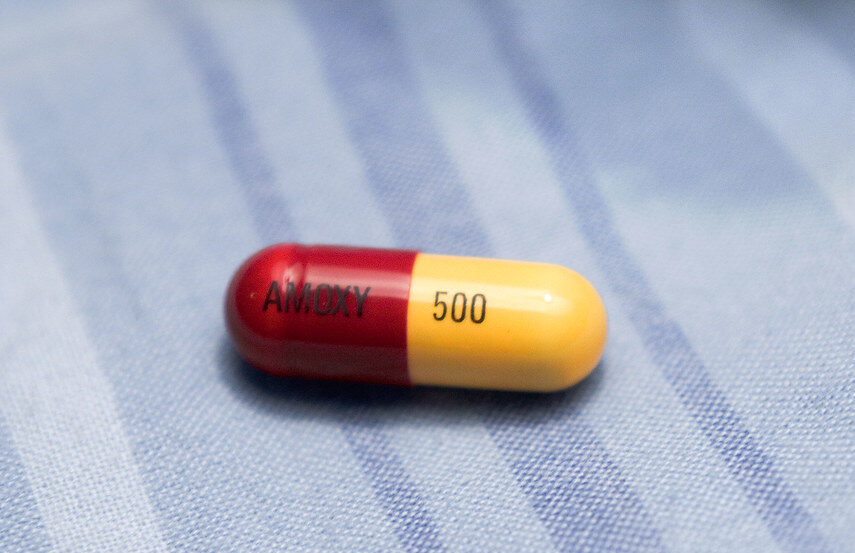

The SECUREBLIS MINI from ACG is a state-of-the-art containment solution specifically engineered for blister packaging in the pharmaceutical industry. Designed to safely handle highly potent active pharmaceutical ingredients (HPAPIs), it operates under negative pressure environments to minimize operator exposure and ensure compliance with Operational Exposure Band (OEB) 3 standards. The SECUREBLIS MINI is versatile, capable of processing pharmaceutical tablets, hard capsules, and soft gelatine capsules with applications ranging from pain relief to multivitamins.

This machine integrates seamlessly into existing production lines, supporting both thermoforming and cold-forming processes with forming capabilities up to 25 cycles per minute and a maximum forming depth of 12 mm. It features advanced automation, including a wet-in-place (WIP) cleaning system complemented by HEPA filters, which ensures a contaminant-free environment. Its strategic glove ports allow manual interventions without compromising containment, enhancing safety and operational efficiency.

With options to utilize various forming materials, such as PVC and cold-form foil, and lidding materials including child-resistant and tropical foil, the SECUREBLIS MINI offers robust versatility. Its design facilitates fast, safe cleaning and changeovers, reducing downtime and improving throughput. Compliance with GMP and other pharmaceutical standards makes it an ideal solution for companies focusing on regulatory adherence and operator safety.

Benefits

- Enhances operator safety by maintaining a contained environment, preventing exposure to high-potency compounds.

- Improves production efficiency with quick changeovers, minimizing downtime.

- Ensures regulatory compliance with GMP and OEB 3 standards.

- Reduces cross-contamination risk with effective HEPA filtration and wet-in-place cleaning.

- Facilitates seamless integration into existing blister packaging lines for versatile operation.

- Applications

- Soft gelatine capsules, Hard capsules, Pharmaceutical tablets

- End products

- Ibuprofen soft gel capsules, Vitamin d capsules, Anti-inflammatory capsules, Amoxicillin capsules, Probiotic capsules, Acetaminophen soft gels, Calcium supplements, Omega-3 fish oil soft gels, Multivitamin tablets, Pain relief tablets

- Steps before

- Granulation, Pelletisation, Encapsulation

- Steps after

- Packing, Cartoning, Vision Inspection

- Input ingredients

- tablets, hard capsules, soft gelatine capsules, HPAPIs, PVC, PVC/PVdC, Triplex (PVC/PE/PVdC), cold-form foil (Alu), push-through foil, child-resistant foil, peelable (paper), tropical foil, aluminium-based laminates

- Output ingredients

- blister packaged tablets, blister packaged hard capsules, blister packaged soft gelatine capsules, contained HPAPIs, sealed blister packs

- Market info

- ACG World is known for manufacturing capsules and capsule filling machines, providing integrated pharmaceutical solutions with a strong reputation for innovation, quality, and comprehensive service offerings in the pharmaceutical manufacturing industry.

- Forming cycle - Thermoforming

- Up to 25 cycles/min

- Forming cycle - Cold-forming

- Up to 20 cycles/min

- Forming depth - Thermoforming

- Up to 12 mm

- Forming depth - Cold-forming

- Up to 9 mm

- Maximum forming area

- 156 mm x 96 mm

- Forming materials

- PVC, PVC/PVdC, Triplex (PVC/PE/PVdC), cold-form foil (Alu)

- Lidding materials

- Push-through foil, child-resistant foil, peelable (paper)

- Batch vs. continuous operation

- Batch

- Automation level

- Automated with PLC

- Changeover time

- Quick changeover enabled

- Cleaning method

- Automated Wet-In-Place (WIP) system

- Containment level

- Operational Exposure Band (OEB) 3

- Cleaning efficiency

- High due to strategic nozzle placement

- Safety interlocks

- Multiple across the machine

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Operational Exposure Band (OEB) Compliance

- OEB 3

- Glove ports location

- Diverse positions for manual interventions

- Negative pressure operating enclosure

- Ensures safety and compliance

- Integration with product loading system

- Allows safe and contained loading

- Wet-in-place (WIP) system

- Automated cleaning process

- HEPA Filters

- Ensures air quality and safety

- Safety interlocks

- Maintain containment conditions