Radiochemistry fume hood

Ensure precise containment and filtration during radiochemical processes, safeguarding both operators and substances with advanced protective measures, critical for sterile injectable pharmaceuticals production and radioactive tracer applications.

Contains and Filters Radiopharmaceutical Emissions

The FHR Radiochemistry Fume Hood from Comecer is expertly engineered to provide robust containment and filtration in radiopharmaceutical and nuclear medicine processes. This hood offers high efficiency with its double-walled aspiration and filtration system, integrating absolute and activated carbon filters within its structure to mitigate hazardous emissions effectively. It supports applications in radiochemistry and aseptic pharmaceutical environments, producing end-products like technetium-99m diagnostic agents and gallium-68 radiolabeling kits. Designed for both liquid and gaseous handling, it features remote controls for fluid management, ensuring sterile and controlled processes.

Constructed from AISI 304 stainless steel with a Scotch-BriteTM finish for durability and corrosion resistance, the workbench is equipped with safety enhancements like a Plexiglas sliding door for front access and a raised edge to prevent spillage. The FHR hood also ensures operational safety and efficiency with its built-in electric gear case for liquid waste discharge and automatic water flow interruption feature.

Meeting stringent CEI standards, this equipment includes two electrical outlets and a manometer for filter status monitoring. It aligns with GMP requirements, making it suitable for installations in hospital pharmacies, pharmaceutical manufacturers, and nuclear medicine facilities. The inclusion of user-friendly features, like a diaphragm keyboard and photoelectric sensors for foot-activated water control, further facilitate seamless integration into your laboratory or processing environments.

Benefits

- Enhances safety and control in radiopharmaceutical production with robust containment and filtration systems.

- Optimizes operational efficiency with automated fluid management and waste discharge.

- Complies with GMP standards, ensuring suitability for pharmaceutical and nuclear environments.

- Minimizes contamination risk with easy-to-clean surfaces and user-friendly design.

- Ensures durability and corrosion resistance with AISI 304 stainless steel construction.

- Applications

- Radiochemistry, Industrial radiopharma, Radiopharmaceuticals, Aseptic processing, Nuclear medicine, Pharmaceuticals

- End products

- Aseptic pharmaceuticals in vial form, Positron emission tomography radiotracers, Technetium-99m-based diagnostic agents, Sterile solutions in syringes, Fluorodeoxyglucose (fdg) for pet scans, Yttrium-90 microspheres, Radioactive tracers, Gallium-68 radiolabeling kits, Iodine-131 therapeutic capsules, Sterile injectable pharmaceuticals

- Steps before

- Decontamination, Setup of equipment, Installation of filter canister, Preparation of chemicals

- Steps after

- Controlled waste discharge, Decontamination cleaning, Filter replacement, Quality control

- Input ingredients

- gaseous fluids, liquid fluids, radioactive materials, electricity for sockets

- Output ingredients

- filtered air, radioactive liquid waste, solid waste

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Material

- AISI 304 INOX stainless steel

- Finish

- Scotch-Brite, trade

- Air speed

- 50 cm/sec

- Filtration system

- Absolute and activated carbon filters

- Liquid waste discharge

- 20 liters polyethylene bin

- Water flow control

- Photoelectric cells

- Electrical outlets

- 2 outlets

- Filtration blockage detection

- Manometer

- Automation level

- Remote control for water adjustment

- Capacity (solid waste)

- 20 liters polyethylene container

- Front closing mechanism

- Plexiglas vertical sliding door

- Airflow control

- Adjustable by-pass

- Air speed

- 50 cm/sec

- Filtration system

- Absolute and activated carbon filters

- Liquid waste discharge

- Controlled discharge into polyethylene bin

- Solid waste discharge

- Controlled discharge into polyethylene container

- Automation level

- Remote control for water and gas

- Water flow control

- Photoelectric cells controlled by feet

- Filter replacement safety

- Protected replacement with canister

- Flow interruption mechanism

- Automatic water flow interruption

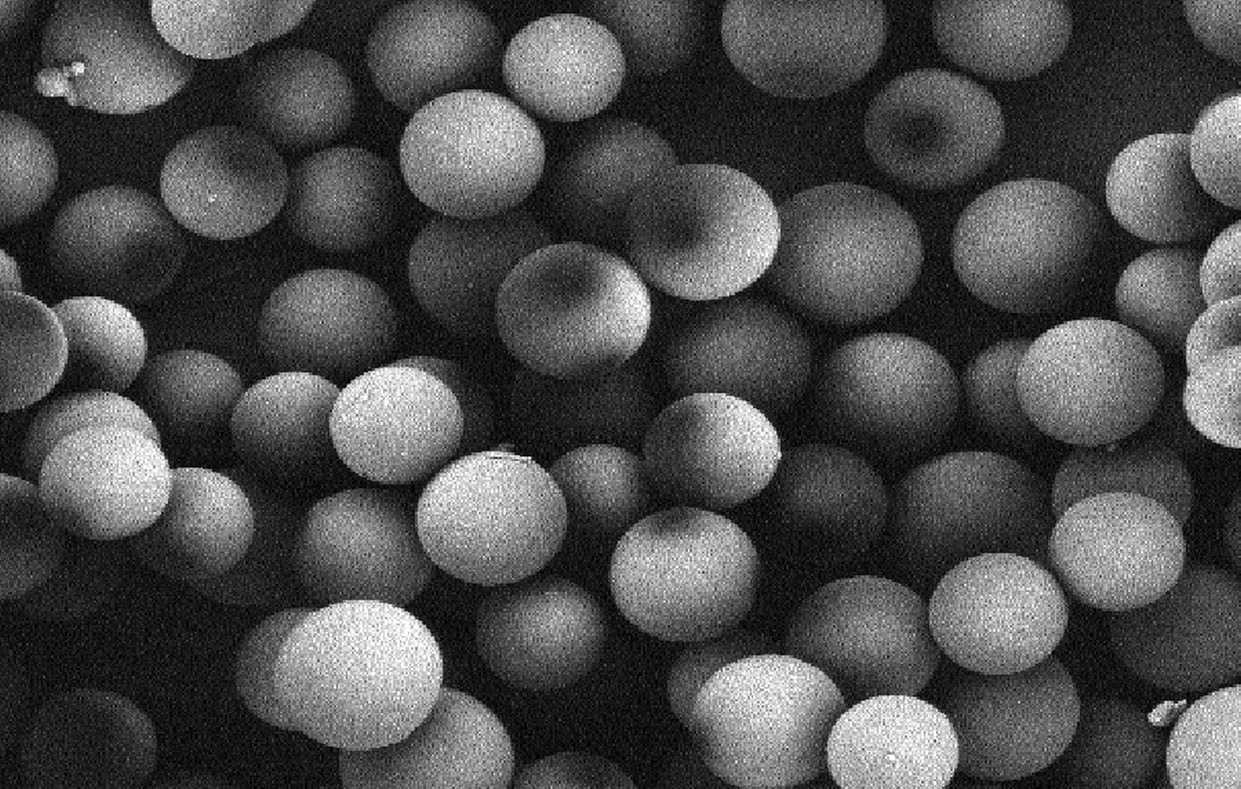

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material

- AISI 304 INOX stainless steel

- Finish

- Scotch-BriteTM

- Worktop feature

- Raised edge

- Front closing

- Plexiglas vertical sliding door

- Panel thickness

- 15/10 thick, AISI 304 stainless steel

- Filtration system

- Absolute and activated carbon filters

- Container capacity

- 20 liter polyethylene container

- Discharge method

- Controlled discharge of radioactive liquid and solid waste

- Control panel type

- Diaphragm Keyboard with decontaminable surface

- Acrylic glass slide rail

- Front closing with Plexiglas vertical sliding door

- Filter replacement

- Protected replacement of the filter with canister equipped with gullet for the positioning of the barrier sack

- Remote control

- Hot/cold water adjustment, Gas spout

- Discharge method

- Controlled discharge for solid and radioactive liquid waste

- Airflow control

- Adjustable by-pass of the air flow