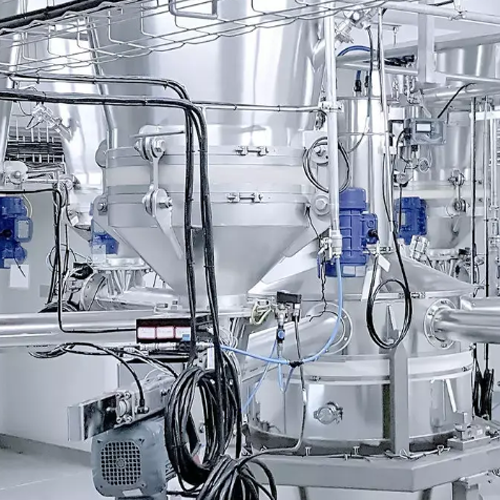

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uniform distribution of ingredients in powder formulations, crucial for maintaining product quality and consistency across batch productions.

Agglomerates and Dries Diverse Material Streams

Hosokawa Micron’s industrial agglomeration and drying system offers precise control in handling diverse powders and granules across multiple industries. Utilizing a combination of advanced vacuum and freeze drying techniques, it efficiently agglomerates and dries materials like soy protein isolates and battery components. The system can process batch and continuous operations with up to 20 tons per hour throughput, ensuring seamless integration into existing lines with PLC-controlled automation and remote monitoring. Its energy-efficient design reduces consumption by 30% with optimized motor control, and is crafted from corrosion-resistant stainless steel to meet stringent GMP and FDA standards, perfect for pharmaceutical applications. Additionally, a built-in CIP system eases cleaning, minimizing downtime while ensuring contamination-free operations. Tailoring options, from rotor speed adjustments to chamber modifications, are available to meet specific production requirements, providing extensive engineering support through Hosokawa’s expertise.

Benefits

- Maximizes material handling efficiency with up to 20 tons per hour throughput.

- Reduces energy usage by 30% through optimized motor control, lowering operational costs.

- Ensures compliance with GMP and FDA standards, supporting safe pharmaceutical production.

- Minimizes cleaning downtime with an integrated CIP system for contamination-free maintenance.

- Offers customizable configuration options to meet specific production and engineering needs.

- Applications

- Detergent powders, Nuclear, Press metal powders, Plant-based proteins, Animal-based proteins, Dry powder inhalants (dpi), Toner, Herbs, Pigments, Catalysts, Dairy, Polymers, Cosmetic powders, Residual streams, Kaolin, Additive manufacturing, Spices, Tea, Cocoa, Animal feed, Crop protection, Recovered carbon black, Ceramics, Sugar, Metals, Flavours, Instant soup, Cell culture media, Er tablets, Marine algae, Battery materials, Thickening agents, Gypsum, Apis, Lactose, Metal salts

- End products

- Copper sulfate crystals, Paprika powder, Laser printer toner, Zeolite catalysts, Lithium-ion battery components, Dehydrated basil, Uranium pellets, Recycled carbon black pellets, Face foundation powders, Dehydrated soup mix, Xanthan gum, Polyethylene granules, Fiber supplements, Albuterol sulfate for inhalers, Titanium alloy powders, China clay, Plaster of paris, Enteric-coated aspirin tablets, Porcelain clay, Whey protein concentrate, Whey protein isolate, Fish meal, Pesticide granules, Aluminum powder, Stem cell culture media, Spirulina powder, Granulated sugar, Black tea leaves, Milk powder, Steel dust, Vanilla extract powder, Laundry detergents, Inkjet printer cartridges, Paracetamol api, Soy protein isolates, Chocolate powders

- Steps before

- Ingredient Grinding, Material Purification, Initial Drying, Raw Material Blending

- Steps after

- Product Cooling, Sterilization, Packaging, Quality Testing

- Input ingredients

- plant-based proteins, animal feed, marine algae, chemical additives, detergent powders, pigments, toner, polymers, carbon black, cocoa, dairy, lactose, flavours, instant soup, animal-based proteins, spices, herbs, sugar, tea, thickening agents, battery materials, metal salts, metal powders, minerals, ceramics, gypsum, kaolin, APIs, cell culture media, dry powder inhalants, ER tablets, cosmetic powders

- Output ingredients

- processed plant-based proteins, processed animal feed, processed marine algae products, manufactured chemicals, cleaning agents, colored pigments, printed materials, finished polymers, recycled carbon black, processed cocoa, dairy products, instant beverage mixes, protein products, processed spices, herbal products, sweeteners, processed tea, thickened products, battery components, nuclear materials, metal products, processed minerals, ceramic products, plaster products, cosmetic products, pharmaceuticals

- Market info

- Hosokawa Micron is renowned for specializing in the manufacturing of powder and particle processing technologies, including mixing, drying, and milling equipment. They are respected for their innovative solutions and engineering excellence in industrial engineered-to-order equipment markets.

- Automation

- PLC-controlled

- Batch size

- Varies based on equipment

- Capacity

- Varies based on equipment

- Cycle time

- 15–60 min

- Drying time

- 10–180 min

- Feed rate

- 50–2000 kg/h

- Filling speed

- 10k–150k/hr

- Filling volume

- 1 ml – 5 L

- Pressure rating

- As per specific equipment

- Temperature range

- Varies based on process

- Vacuum level

- Up to 0.1 mbar

- Working mechanism

- Flexomix, Ribbon Screw, etc.

- Integrated steps

- Mixing, Drying, Size Reduction

- CIP/SIP

- Available

- Batch vs. continuous flow

- Both options available

- Automation level

- PLC / SCADA

- Energy efficiency

- Optimized for low energy use

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Yes/No

- Conical shape

- Conical Screw Mixer, Conical Paddle Mixer

- Bowl or tank shape

- Vertical / Horizontal

- Feed method

- Pneumatic / Gravity-fed

- Discharge method

- Valve / Open-bottom

- Control panel type

- PLC / HMI integrated

- Integration possibilities

- SCADA / MES integration

- Automation level

- Manual / PLC / SCADA

- Discharge method

- Pneumatic / Mechanical

- Drying integration

- Stand-alone / Inline

- Energy efficiency configurations

- Variable speed drives

- Automation

- PLC-controlled / Manual

- Defrost system

- Automatic / Manual

- Batch documentation

- Auto recording / Manual logging