Industrial rotary sifter for bulk materials

Ensure precision and quality in your production line with a robust solution designed to efficiently sift and filter bulk materials, removing contaminants and verifying grain sizes for consistent end-product quality.

Screens and Verifies Bulk Material Consistency

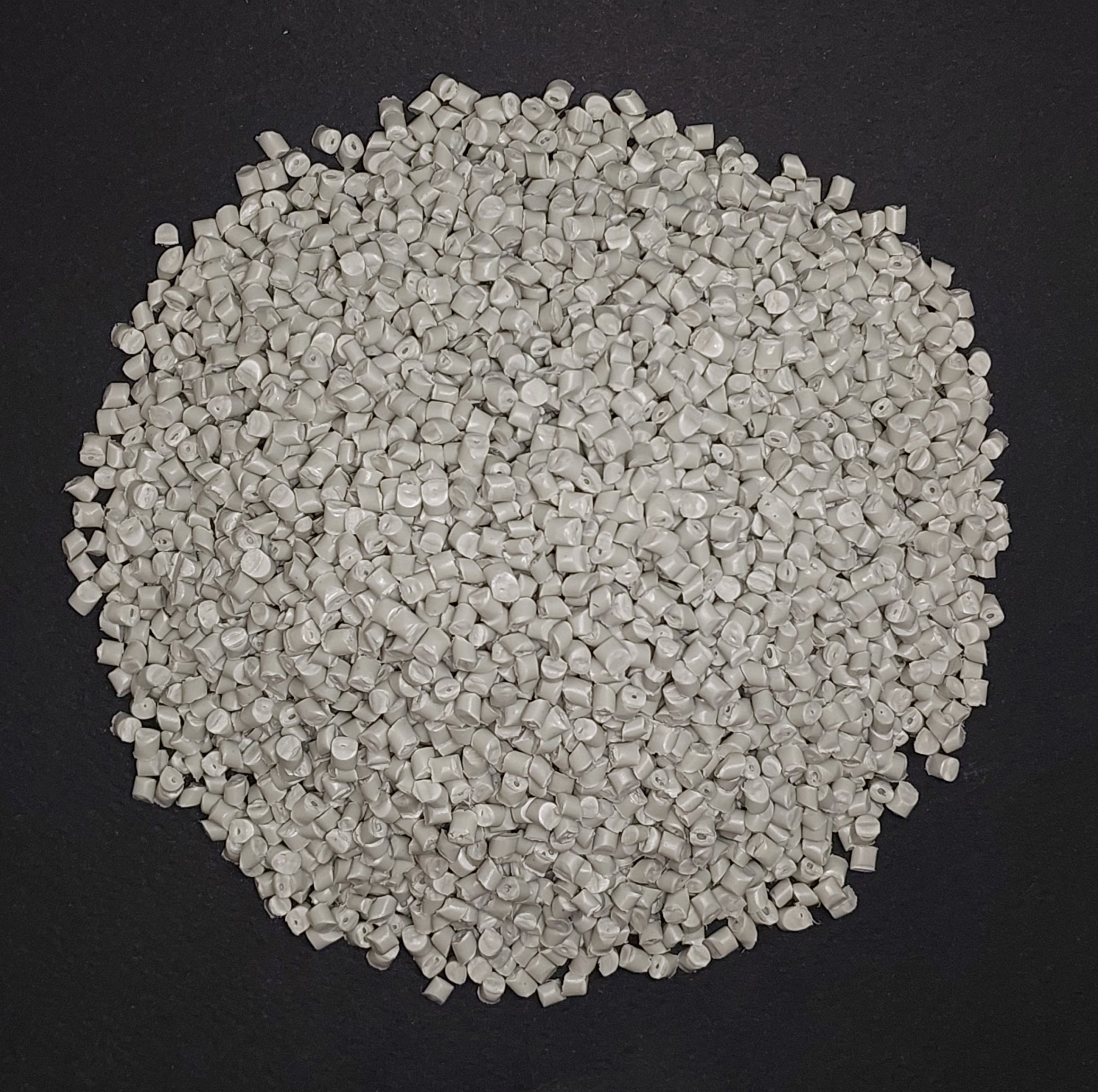

Zeppelin Systems’ RS Rotary Sifter and TS Drum Screen are engineered-to-order screening machines that excel in quality control for bulk material processing. They utilize a robust rotary sifting mechanism and specialized drum screens to separate contaminants and verify particle size in continuous operations. Widely adopted across the food, plastics, carbon black, and rubber industries, these systems handle materials such as flour, polyethylene pellets, and tire crumb rubber with precision. The RS Rotary Sifter ensures reliable inline sifting with options to withstand up to 0.8 bars of overpressure or vacuum in pneumatic conveying lines, while both units allow for mesh customization between 0.25 mm and 8 mm. Featuring automatic drum monitoring with Screen-D-Tect and potential for in-situ cleaning, these machines are also designed in compliance with ATEX Directive 94/9/EC for operations in explosive atmospheres. The use of durable materials like polyester and VA stainless steel alongside easy maintenance access makes them an optimal choice for purity-critical and high-throughput environments, with customization options available to fit specific production line requirements.

Benefits

- Enhances product purity by effectively removing foreign materials and verifying particle sizes.

- Lowers maintenance time with easy access for cleaning and optional in-situ cleaning features.

- Ensures continuous operation with automatic screen monitoring that prevents production interruptions.

- Complies with ATEX safety standards, allowing use in explosive environments and ensuring operational safety.

- Customizes to fit specific processing needs with adjustable mesh sizes, optimizing material handling efficiency.

- Applications

- Plastics industry, Food industry, Rubber and tire industry, Carbon black industry

- End products

- Polyethylene pellets, Polypropylene granules, Powdered sugar, Rice starch, Tire crumb rubber, Flour, Carbon black powder, Rubber granules

- Steps before

- Purification, Drying, Grinding

- Steps after

- Quality Control, Packing, Coating

- Input ingredients

- bulk material, grain, raw materials, plastics, carbon black, foreign bodies, coarse material

- Output ingredients

- processed bulk material, verified grain sizes, separated coarse material, loosened product lumps, foreign material removed

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Sifter Drum Material

- Polyester / VA stainless steel

- Mesh Size

- 0.25 mm – 8 mm

- Pressure Compatibility

- Up to 0.8 bars

- Compliance with Standards

- EHEDG guidelines

- Usage in ATEX Zones

- Zone 21 / 22

- Automation

- Screen-D-Tect monitoring

- Cleaning Method

- Automatic / Manual

- Vibration

- Low-vibration

- Inspection Feature

- Inspection openings on sifter

- Working Mechanism

- Rotary Sifting

- Batch vs. Continuous Operation

- Continuous

- Changeover Time

- Fast through inspection openings

- Cleaning Method

- Manual / CIP possible

- Automation Level

- PLC-controlled with optional Screen-D-Tect

- Pressure Capacity

- Up to 0.8 bars

- Usability under Vacuum/Pressure

- Yes

- Mesh Size Range

- 0.25 mm to 8 mm

- Density/particle size

- 0.25 mm to 8 mm

- Machine footprint

- Compact

- Sifter drum material

- Polyester / VA stainless steel

- Sifter drum mesh size

- 0.25 mm to 8 mm

- Discharge method

- Inline / Pressure-tight use

- Compact footprint

- Yes

- Inspection opening

- Side of sifter

- Sifter drum shape

- Slotted (for heavy-duty)

- Control panel type

- Manual / PLC / SCADA

- Sifter drum material

- Polyester / VA stainless steel

- Mesh size of sifter drum

- 0.25 mm to 8 mm

- Zone classification

- Zone 21 / Zone 22

- Sifter drum monitoring

- Screen-D-Tect

- Automatic cleaning

- Yes

- Overpressure or vacuum capability

- Up to 0.8 bars