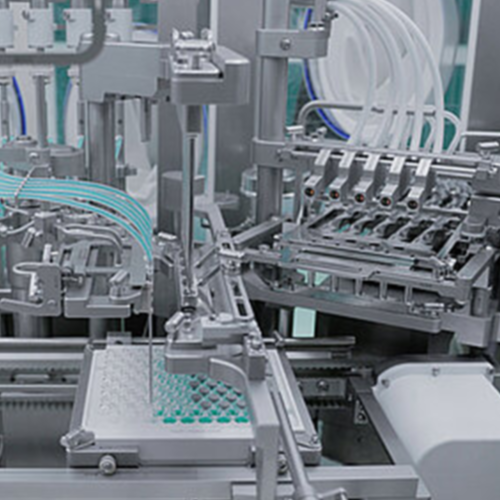

Vial and syringe filling system for pharmaceuticals

Ensure aseptic precision in liquid formulation filling with a modular system designed for rapid turnaround and compliance with stringent regulatory standards, streamlining the production of sterile syringes and pre-filled vials.

Fills and Seals Aseptic Vials, Syringes, and Cartridges

The flexfill from groninger is a modular aseptic filling machine designed to streamline the production of sterile liquid pharmaceuticals. Its unique modular design allows for rapid deployment and customization, meeting medium production volumes for pharmaceutical manufacturers and CDMOs. The system efficiently handles debagging, transfer, opening, filling, closing, denesting, and sealing processes for vials, syringes, and cartridges. Featuring flexible filling systems, including rotary piston and peristaltic pumps, it accommodates a variety of product viscosities and oxygen-sensitive formulations, with optional gassing and vacuum capabilities. Compliant with major regulatory standards, flexfill ensures high process reliability with automated clamping, cutting, and In-Process-Control (IPC) to maximize output. The hygienic design supports fast cleaning, integrating into existing lines with ease and leveraging groninger’s high-end capping technology for minimized particle generation during sealing. Available with advanced camera systems for precise quality control, it meets GMP standards, providing pharmaceutical and biopharmaceutical manufacturers with a reliable solution for aseptic filling.

Benefits

- Accelerates time to market with rapid deployment and modular customization.

- Enhances product safety with aseptic no-touch transfer and controlled processing.

- Increases production efficiency with automated IPC for optimal filling accuracy.

- Simplifies integration and cleaning, supporting seamless line incorporation.

- Ensures regulatory compliance, meeting GMP standards for pharmaceutical production.

- Applications

- Liquid formulations, Biopharmaceuticals, Aseptic products, Pharmaceuticals

- End products

- Ready-to-use cartridges, Sterile syringes, Injectable biologics, Ophthalmic solutions, Pre-filled vials, Iv solutions

- Steps before

- Debagging, No-touch transfer (NTT), Sorting of closures

- Steps after

- Denesting, Sealing, Transfer Module with tub reject handling

- Input ingredients

- vials, syringes, cartridges, ready-to-use containers, closures, stopper

- Output ingredients

- filled vials, filled syringes, filled cartridges, sealed vials, sealed syringes, sealed cartridges

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Filling method

- Rotary piston and/or peristaltic pump

- Filling accuracy

- Not specified

- Filling speed

- Not specified

- Filling capacity

- Medium production volumes

- Automation

- Automatic clamping and cutting

- Pre-configured modules

- Available

- No-touch transfer

- Grade A aseptic transfer

- In-Process-Control (IPC)

- For filling

- Oxygen sensitive gassing

- Available

- Vacuum for high viscous products

- Available

- Sorting of closures

- Feeding tracks

- Hygienic design

- Fast and easy cleaning

- Standard gassing and vacuum functions

- Available

- Camera system for stopper presence

- Available

- Sealing process

- Low particle generation

- Crimp quality control

- Camera tracking

- Automation level

- High (PLC with customizable modules)

- Batch vs. continuous operation

- Batch and inline flexible

- CIP/SIP

- CIP compatible, hygienic design

- Cleaning method

- Easy cleaning operations

- Changeover time

- Quick with modular design

- Energy efficiency

- Balanced for operational cost reduction

- Biological compatibility

- Aseptic filling

- Cleanability

- Hygienic design for easy cleaning

- Corrosive resistance

- Suitable for polymer containers or cartridges

- Abrasion resistance

- High-end capping technology for low particle generation

- Density/particle size

- Low particle generation during sealing

- Modular design

- Yes

- Flexible filling system

- Rotary piston and/or peristaltic pump

- Aseptic transfer system

- No-touch transfer (NTT) for ready-to-use containers

- Modular machine concept

- Pre-defined configuration

- Pre-configured modules

- Available for individual customization

- Filling system type

- Rotary piston and/or peristaltic pump

- Gassing and vacuum functions

- Standard options available

- Camera systems

- Stopper presence and orientation