Laminar flow shielded cell for radiopharmaceutical research

Ensure aseptic conditions and precise dose calibration for isotopic vials and radioactive fluids with a modular laminar flow system designed to safeguard research lab operatives.

Ensures Aseptic Handling of Radiopharmaceuticals

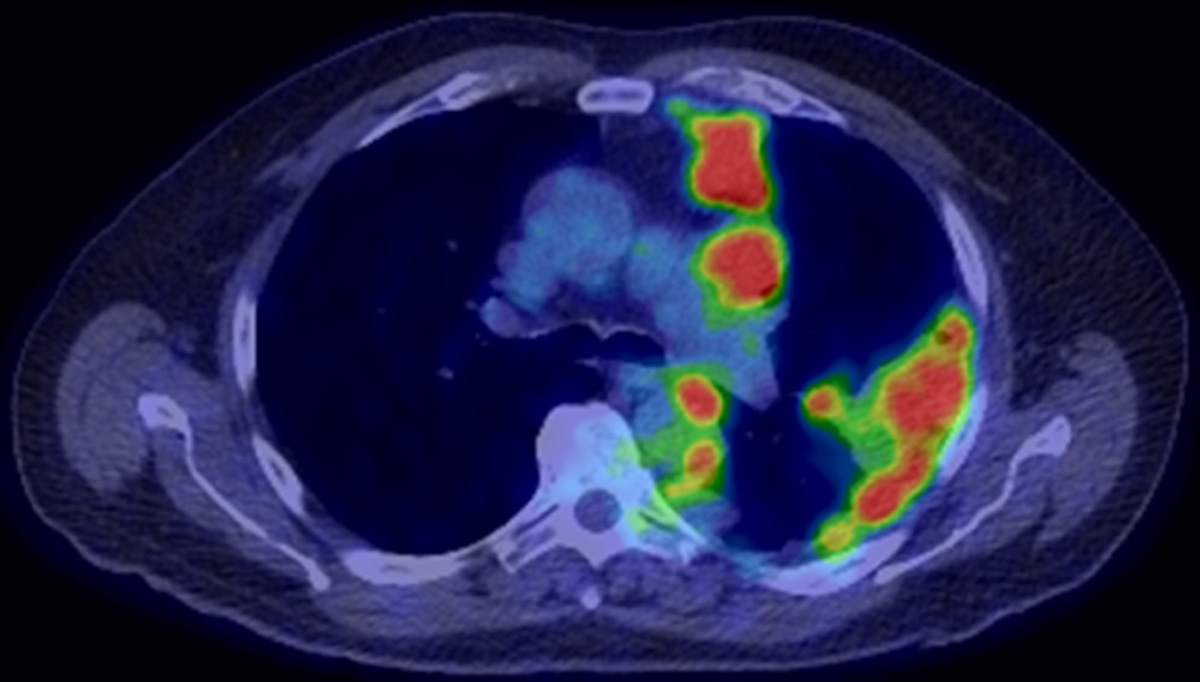

The MIP LAF Series by Comecer is a series of specialized Laminar Flow Shielded Cells designed for radiopharmacy and nuclear medicine applications. These units are essential for aseptic handling and dispensing of radiochemicals and radiopharmaceuticals, such as FDG and Technetium-99m. Featuring a full laminar air flow working area and modular design, these cells integrate seamlessly into lab environments, offering advanced fluid handling and dose calibration through airtight connections and automated pressure adjustments using modulating valves. Built with AISI 316L stainless steel, they offer exceptional corrosion resistance and comply with cGMP standards. Equipped with high sensitivity tele-pliers and a touch-screen interface, they enable precise manual operation and monitoring. Designed for integration into a wider processing line, these cells offer compatibility with radiochemistry modules and provide flexible configurations, including options for telemanipulators and shielded pre-chambers. This series is optimized for safe, continuous operations, offering robust solutions for product and vial extraction while maintaining necessary shielding with 75 mm lead walls.

Benefits

- Ensures operator safety with a shielded design and secure vial extraction system.

- Enhances aseptic conditions, minimizing contamination risk in radiopharmaceutical production.

- Increases operational efficiency with a modular, customizable configuration.

- Provides reliable dose calibration and fluid handling for diverse end-products.

- Simplifies maintenance with corrosion-resistant materials and easy-access components.

- Applications

- Radiopharmaceuticals, Radiochemicals, Isotope vials, Radioactive fluids, Nuclear medicine

- End products

- Iodine-123 tablets, Technetium-99m-based radiopharmaceuticals, Strontium-89 chloride injections, Gallium-68 generators, Lutetium-177 therapies, Molybdenum-99/technetium-99m generators, Fluorodeoxyglucose (fdg), Carbon-11 radiotracers, Iodine-131 capsules, Yttrium-90 microspheres

- Steps before

- Radiopharmaceutical synthesis, Radioactive fluid preparation, Dispensing system setup

- Steps after

- Dose calibration, Sterilization, Waste collection and disposal, Quality control

- Input ingredients

- radioactive fluids, isotope vials, vial for dose calibration

- Output ingredients

- calibrated vials, waste collection, vial extraction

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Laminar Air Flow

- Full laminar air flow working area

- Modular Design

- Flexible configuration

- Touch Screen

- Hot cell and dispensing system

- Airtight Connections

- For radioactive fluids

- Material

- AISI 316L stainless steel

- Shut-off Valves

- Ball shut-off valves

- Filter Leakage Test

- DOP test connections

- Automatic Pressure Adjustment

- Modulating valves

- Tele-plier Sensitivity

- High sensitivity tele-pliers

- Movement Mechanism

- Ball bearings

- Dose Calibrator

- 2 Ci or 20 Ci with touch screen console

- Product Extraction System

- Drawing System

- Air Pressure

- Continuous negative pressure

- Door Gaskets

- Inflatable gaskets around door perimeter

- Shielding Material

- 75 mm thick lead

- Mirror-Bright Finish

- AISI 316L stainless steel

- Ion Chamber Compartment

- Shielded ion chamber, connected with working area

- Laminar flow

- Full laminar air flow

- Modular design

- Flexible configuration

- Automation level

- Touch screen control

- Pressure control

- Automatic adjustment by modulating valves

- Radiation protection

- Lead shielding, 75 mm thick

- Waste management

- Shielded waste compartment

- Particle counting

- Particle counter connection

- Vial extraction

- Comecer Drawing System

- Aseptic operation

- cGMP compliant

- Ventilation

- Continuous negative pressure

- Cleanability

- cGMP compliant laminar flow

- Corrosive resistance (e.g. acids)

- AISI 316L stainless steel

- Radioactive Fluid Handling

- Airtight connections

- Footprint

- Modular design

- Material

- AISI 316L stainless steel

- Shielding Thickness

- 75 mm lead

- Internal Surface Finish

- Mirror-Bright

- Door Type

- Shielded with lead glass window

- Flow Type

- Laminar flow

- Ventilation Pressure

- Continuous negative pressure

- Inflatable Gaskets

- Ensures perfect door closing

- Tele-pliers

- High sensitivity, movement by ball bearings

- Control panel type

- Touchscreen

- Integration possibilities

- IIoT platform integration

- Modular design

- Flexible configuration

- Telemanipulator options

- Several models available

- Pre-chamber options

- Shielded or not shielded

- Tele-plier type

- Manual / High sensitivity