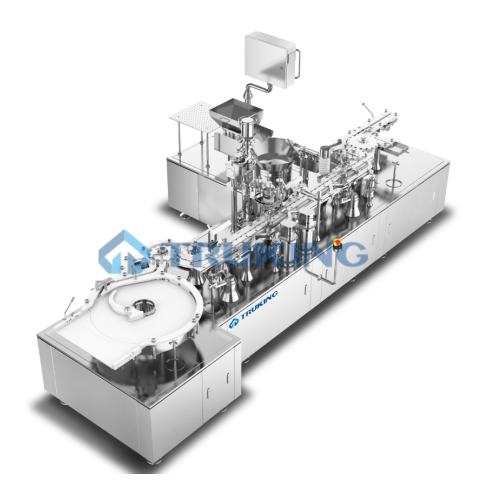

Vial powder dispensing system

Optimize your aseptic fill process with high-precision powder dispensing that minimizes contamination risk and ensures consistent dosage accuracy in pharmaceutical production lines.

Fills and Stopper Powders for Aseptic Production

The TRUKING PDS Series Powder Filling and Stoppering Machine provides pharmaceutical manufacturers with reliable, high-precision aseptic filling solutions. This fully servo-driven system supports a wide application range from 2 to 100 ml and ensures minimal breakage and vibration during operation. Ideal for producing vaccines, insulin, and other critical pharmaceuticals, it achieves precise dosage, critical for maintaining product efficacy. Automated with an industrial PC control system, it offers state-of-the-art audit trailing and data integrity functions while complying with 21 CFR Part 11 standards. The compact design accommodates varying floor plans, optimizing cleanroom space, and features superior 316L stainless steel contact surfaces for uncompromising cleaning. In-house containment up to OEL 5 enables integration of customized RABS and Isolators, ensuring ultimate performance and safety. Designed for seamless integration and ease of maintenance, it includes CIP and SIP functions for efficient cleaning, along with pre and post nitrogen purging to maintain inert conditions.

Benefits

- Ensures contamination-free production, critical for aseptic processes.

- Optimizes cleanroom space with compact, modular design.

- Complements stringent regulatory standards, preserving product safety.

- Enhances operational efficiency with precise automated dosing.

- Facilitates easy cleaning and maintenance, reducing operational downtime.

- Applications

- Solid preparations, Oral liquid products, Lyophilized products, Soft bag products, Ampoules, Pre-filled syringes, Traditional chinese medicines, Injectables, Bfs products, Diagnostic reagents

- End products

- Vitamin b12 ampoules, Protein powders, Calcium tablets, Vaccines, Single-dose pre-filled syringes of heparin, Pain relief injections, Insulin, Metered dose eye drops, Antibiotics, Liquid cough syrups, Antibody drugs, Sterile demineralized water bags, Herbal tinctures, Blood glucose monitoring strips, Multivitamin tablets, Ginseng extract, Electrolyte solutions

- Steps before

- Extraction, Concentration, Drying, Purification, Separation, Preparation System, Bioreactor System, Reaction Tank, Crystallization Tank

- Steps after

- Sterilization, Packing, Inspection, Leakage Testing, Coating, Tablet Pressing, Storage Distribution

- Input ingredients

- Vials, Power dosage, Inert gas, Oxygen content, Containers, Ready-for-application vials

- Output ingredients

- Aseptic fill finish, Lyophilization production, Ampoule production, Pre-Filled Syringe production, BFS production, Softbag production, Oral preparation, Packaged and inspected products

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Fully Servo-driven

- Filling accuracy

- Highly accurate powder dosage systems

- Containment level

- Up to OEL 5

- CIP/SIP

- Online CIP, SIP function

- Nitrogen purging stations

- Pre, Post nitrogen purging

- Filling range

- 2 to 100ml

- Cleaning material

- SS 316L

- Compliance

- 21 CFR Part 11

- Control system

- Industrial PC control

- Design

- Compact footprint

- Performance parameters

- GAMP, cGMP, FDA compliance

- Error handling

- Graphical debugging

- Working mechanism

- Servo-driven, intermittent motion

- Integrated steps

- Filling, stoppering, nitrogen purging

- CIP/SIP

- Online CIP, SIP function

- Batch vs. continuous operation

- Batch

- Automation level

- Industrial PC-controlled

- Cleaning method

- CIP

- Energy efficiency

- High throughput with minimum breakage

- Changeover time

- Compact design for quick changeover

- Air incorporation control

- Nitrogen purging stations

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Compact foot print design with modular customization

- Control panel type

- Industrial PC control

- Container type

- Vials

- Material

- SS 316L product contact design

- Control panel type

- Industrial PC control with state of art features

- Discharge method

- Customizable based on client requirements

- Integration with RABS/Isolators

- O-RABS, C-RABS, Isolator

- Footprint customization

- Compact footprint design

- Nitrogen purging stations

- Pre, Post nitrogen purging