Downflow booths for hazardous material processing

Ensure product integrity and operator safety during hazardous material handling with advanced air filtration and containment solutions.

Provides Containment and Filters Air for Safety

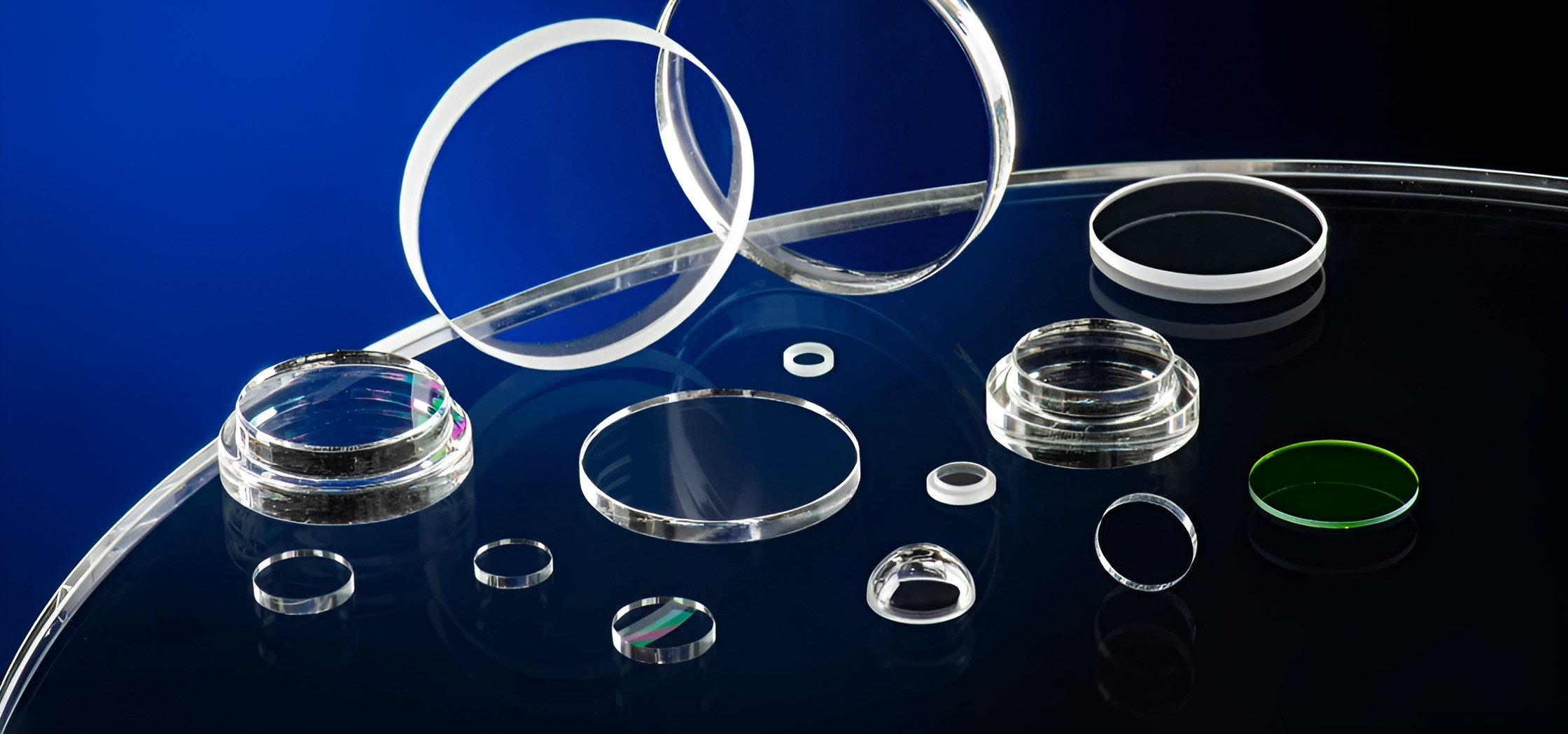

The Telstar Downflow Booths are designed to meet stringent containment and air filtration requirements across diverse industries such as pharmaceuticals, chemicals, and robotics. Featuring ISO 5 air quality and negative pressure, these booths ensure triple protection for products, operators, and the environment. They are ideal for handling active pharmaceutical ingredients, chemical solvents, and optical components, offering modular customization to fit specific production needs.

Equipped with an efficient air handling system, Telstar Downflow Booths provide continuous contamination control, making them suitable for operations involving hazardous materials. Available in both standard and custom-built modular series, they can be integrated with additional equipment like scales and lifters, enhancing overall production line efficiency.

These booths are fully compliant with ISO 14644-1 and cGMP guidelines, ensuring stringent manufacturing standards are upheld. Designed with user-friendly features such as a complete 3D model and low maintenance requirements, they incorporate green technology options to optimize energy consumption. With ATEX explosion-proof versions, they cater to industries requiring robust safety measures against gas and dust hazards.

Benefits

- Enhances worker safety with robust containment and air filtration systems.

- Ensures product quality through ISO 5 air cleanliness standards.

- Offers flexible integration with existing production lines to boost operational efficiency.

- Reduces environmental impact with energy-efficient green technology options.

- Complies with ISO and cGMP guidelines, ensuring high manufacturing standards.

- Applications

- Optical components, Veterinary medicines, Robotics components, Chemical products, Healthcare diagnostics and therapy, Food products, Pharmaceuticals

- End products

- Active pharmaceutical ingredients, Optical lenses, Diagnostic test kits, Industrial solvents, Packaged snacks, Robotic sensors, Veterinary tablets

- Steps before

- Material Preparation, Grinding, Weighing, Dispensing

- Steps after

- Packing, Sterilization, Quality Assurance, Product Testing

- Input ingredients

- hazardous materials, toxic materials, pharmaceutical ingredients, veterinary substances, chemical compounds

- Output ingredients

- ISO 5 air quality environment, contaminant-free products, safe air exhaust

- Market info

- Telstar is known for specializing in the design, engineering, and manufacturing of advanced vacuum and aerospace solutions, gaining a strong reputation for their innovative and customized equipment in pharmaceutical, medical, and scientific research sectors.

- Air Quality

- ISO 5

- Pressure Type

- Negative Pressure

- Protection Types

- Operator, Product, Environment

- Design Type

- Standard and Custom-built Modular

- Energy Efficiency

- Green Technology

- Explosion Proof

- ATEX Versions

- Airflow Control

- 0.1–2 m/s

- Automation Level

- Manual / PLC / SCADA

- Batch vs. Continuous Operation

- Batch / Inline Continuous

- Cleaning Method

- CIP / Manual

- Energy Efficiency

- Low energy consumption

- ISO Air Quality

- ISO 5

- Negative Pressure Maintenance

- Yes

- Safety Measures

- Triple protection for operator, product, and environment

- Customization Flexibility

- Standard / Custom-built Modular

- Integration Capability

- Scales, Screens, HMI, Lifters

- ATEX Explosion Proof Versions

- Available

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- Scales, screens, HMI, lifters

- Explosion proof version

- ATEX (gas and dust)

- Modular Design

- Standard and custom-built

- Customization support

- Dedicated professional team

- Compliance Options

- ISO 14644-1, cGMP, ISPE