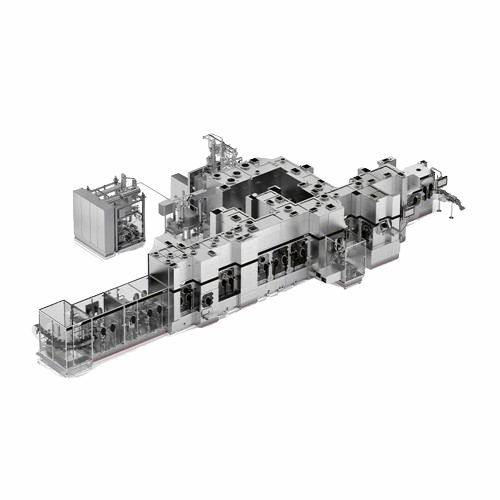

Isolation solutions for aseptic fill-finish lines

Achieve maximum product sterility with advanced isolation solutions, minimizing contamination risks in aseptic fill-finish lines. Designed to handle potent compounds, this technology ensures rigorous cross-contamination control and operator safety in pharmaceutical production environments.

Ensures Aseptic Filling and Cross-Contamination Control

Developed by IMA Life, the ISOLATION TECHNOLOGY system is integral to aseptic fill-finish lines, particularly for pharmaceutical and biotech sectors. It minimizes human intervention with automated filling systems, ensuring sterility and containment for liquid and powder products like injectable vaccines and cytotoxic drugs. Leveraging cross-contamination control expertise, it integrates seamlessly into high-speed, continuous operations. Its robust design offers dedicated HVAC systems and customizable VPHP cycles, compatible with various isolators, vial washers, and alu-capping machines. The system’s energy-efficient components and remote monitoring capabilities enhance its operational efficiency, while its superior material options meet stringent GMP compliance standards. This system simplifies cleaning through integrated spray nozzles and CIP modes, supporting flexible configurations to suit specific processing needs.

Benefits

- Enhances product sterility and operator safety through reduced human intervention.

- Lowers contamination risks with integrated cross-contamination control measures.

- Increases operational efficiency with automated high-speed filling systems.

- Minimizes energy consumption using advanced ventilation and monitoring technologies.

- Customizable configurations meet diverse pharmaceutical processing requirements.

- Applications

- Liquid formulations, Cytotoxic compounds, Sterile products, Powder drugs, Biopharmaceuticals, Pharmaceuticals

- End products

- Cytotoxic drug vials, Monoclonal antibody vials, Liquid cancer treatments, Vials of lyophilized drugs, Hormonal therapy injectables, Antibiotic powders for reconstitution, Pre-filled cartridges for insulin pens, Pre-filled syringes of liquid medication, Powdered antibiotics, Sterile saline bags, Sterile intravenous bags, Injectable vaccines

- Steps before

- Product Preparation, Material Transfer, Vial Infeed

- Steps after

- Sterilization, Packing, Vial Passthrough, Vial Collecting, CIP SIP Mode

- Input ingredients

- liquid products, powder drugs, toxic products, hazardous compounds, potent compounds, cytotoxic compounds

- Output ingredients

- aseptic fill-finish products, vials, multi-chamber sterile bags, sterile powder doses, lyophilized products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Design

- Double wall / Single wall

- Integrated Filtration Design

- Enhanced containment

- Equipment Access

- Fully integrated and easy access

- HVAC System

- Flexible, modular design

- VPHP Cycles

- Customized cycles

- HEPA Filters

- BAG-IN/BAG-OUT in return ducts

- Cleaning Tools

- Spray nozzles and guns

- Sensors

- Specific for ventilation and electrical consumption monitoring

- Sterility Test System

- Unidirectional air flow and constant positive pressure gradient

- Operation Mode

- CIP/SIP - automatic nozzle disconnection

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Design Type

- Double wall / Single wall

- Filtration Design

- Integrated

- Wall Design

- Flush

- Ventilation System

- Dedicated HVAC System

- Cleaning Accessories

- Spray nozzles and guns

- Glove Handling

- Easy

- Size

- TBD

- Sensors

- Accelerometric sensors

- Customization of VPHP cycles

- Yes

- Customization of HVAC System

- Flexible, modular

- Integration of automated systems

- Filling systems for liquids or powders

- Sensors for monitoring

- Accelerometric and consumption sensors