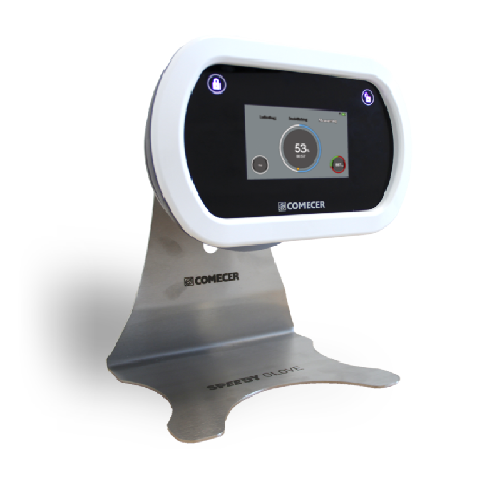

Automatic portable glove tester

Ensure glove integrity in critical environments with rapid, precise leak testing, safeguarding aseptic conditions without disrupting operations.

Performs Leak and Integrity Testing on Gloves

The Speedy Glove from Comecer is a portable glove integrity tester designed to meet the rigorous demands of pharmaceutical and radiopharmaceutical environments. This system is unique due to its rapid inflation feature, shortening test duration by up to 30%. It operates without connection to pneumatic circuits, making it ideal for isolators in aseptic processes, containment processes, and radiopharmaceutical production. The Speedy Glove tester, compatible with all glove flange types, ensures precise leak and integrity testing using a pressure decay method compliant with ISO 14644-7 Annex E.5. It supports real-time pressure monitoring and avoids unnecessary isolator downtime by enabling both inside-to-outside and reverse testing. The device features RFID technology for accurate test traceability and CFR Part 11 compliant data handling, storing up to 1,000 test reports. Its battery-powered, Wi-Fi-ready design integrates easily within existing production lines, contributing to enhanced operational efficiency and compliance with cGMP standards.

Benefits

- Saves time with a rapid inflation system, reducing test duration by 30%.

- Enhances safety and compliance in critical environments with precise detection of glove leaks.

- Increases operational efficiency by enabling continuous workflow without isolator downtime.

- Ensures regulatory compliance with ISO 14644-7 and CFR Part 11 standards.

- Facilitates traceable testing, minimizing human error with RFID technology.

- Applications

- Aseptic processes, Containment processes, Active pharmaceutical ingredients (api), Radiopharmaceuticals, Highly active pharmaceutical ingredients (hapi)

- End products

- Antiviral medications, Hormonal medications, Controlled release tablets, Immunotherapy drugs, Diagnostic radiotracers, Oncology drugs, Therapeutic radiopharmaceuticals, Sterile injectable medications

- Steps before

- Isolator setup, Glove installation, Pressure stabilization, Pre-production qualification

- Steps after

- Post-production qualification, Decontamination, Battery recharging, Report generation

- Input ingredients

- gloves for testing, air for inflation, RFID tags, power (battery)

- Output ingredients

- leak test report, glove integrity status, CSV files, PDF files

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Automation

- Automatic

- Battery-powered

- Yes

- Pressure decay integrity tests

- Yes

- RFID technology

- Yes

- Wi-Fi ready

- Yes

- VPHP compatibility

- Yes

- Rack charging

- Yes

- Compatibility

- All glove flanges on the market

- Inflation system

- Rapid inflation

- Inflation direction

- Inside to outside / Outside to inside

- Report storage

- 1, 000 reports

- Battery recharge time

- 4 hours

- Glove integrity testing mode

- Pressure decay test

- Testing speed

- 3-5 minutes faster per test

- Automation level

- Automatic / Manual

- Testing direction

- Inside to outside / Outside to inside

- Decontamination compatibility

- VPHP (Vaporised Hydrogen Peroxide)

- Use environment

- Aseptic / Containment processes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Glove flange compatibility

- All currently available glove flanges

- Device portability

- Battery-powered

- Touch-screen interface

- Complete touch-screen

- Control panel type

- Touch-screen

- Integration possibilities

- Wi-Fi ready, RFID technology

- Flexibility in mounting

- Compatible with all glove flanges

- Decontamination compatibility

- VPHP compatible

- Portability

- Battery powered

- Charging method

- Rack charging