Shielded cell for radiopharmaceutical synthesis

Ensure operator safety and seamless radiopharmaceutical synthesis with advanced containment and radioprotection technology designed to handle high-energy isotopes efficiently.

Provides Radioprotection and Containment in Synthesis Processes

The Shielded Cells for Synthesis Modules Model MIP from Comecer offer specialized radioprotection and containment solutions for radiopharmaceutical manufacturing and nuclear medicine research. These modular cells are designed to host and protect automated synthesis modules, safeguarding operators and environments from high-energy gamma emissions. With lead shielding up to 100 mm thick, the MIP cells accommodate a range of isotopes, including Technetium-99m to Lutetium-177. Featuring a sealed, negative pressure work chamber equipped with a 7-inch touchscreen, you can monitor and trace critical parameters effortlessly. Built for compliance with cGMP guidelines, this system includes Class B “At rest” air quality and comes standard with a pneumatic elevator for precise isotope calibration. Integration is streamlined with flexible configurations for tele-manipulators and side autoclaves, while airtight connections and stainless steel fluid lines ensure robust contamination control. The MIP series also excels in ease of maintenance, with options for automatic leak testing and removable trays to enhance cleaning processes. Tailored to meet specialized operational needs, this adaptive solution is ideal for radiopharmaceutical, nuclear medicine, and research and development environments.

Benefits

- Enhances operator safety with comprehensive radioprotection, minimizing exposure risks.

- Streamlines isotope calibration and monitoring through intuitive touchscreen controls.

- Maintains optimal air quality and contamination control via advanced filtration and negative pressure systems.

- Ensures regulatory compliance with cGMP standards, reducing validation time and cost.

- Facilitates seamless integration and adaptability with modular design and flexible configuration options.

- Applications

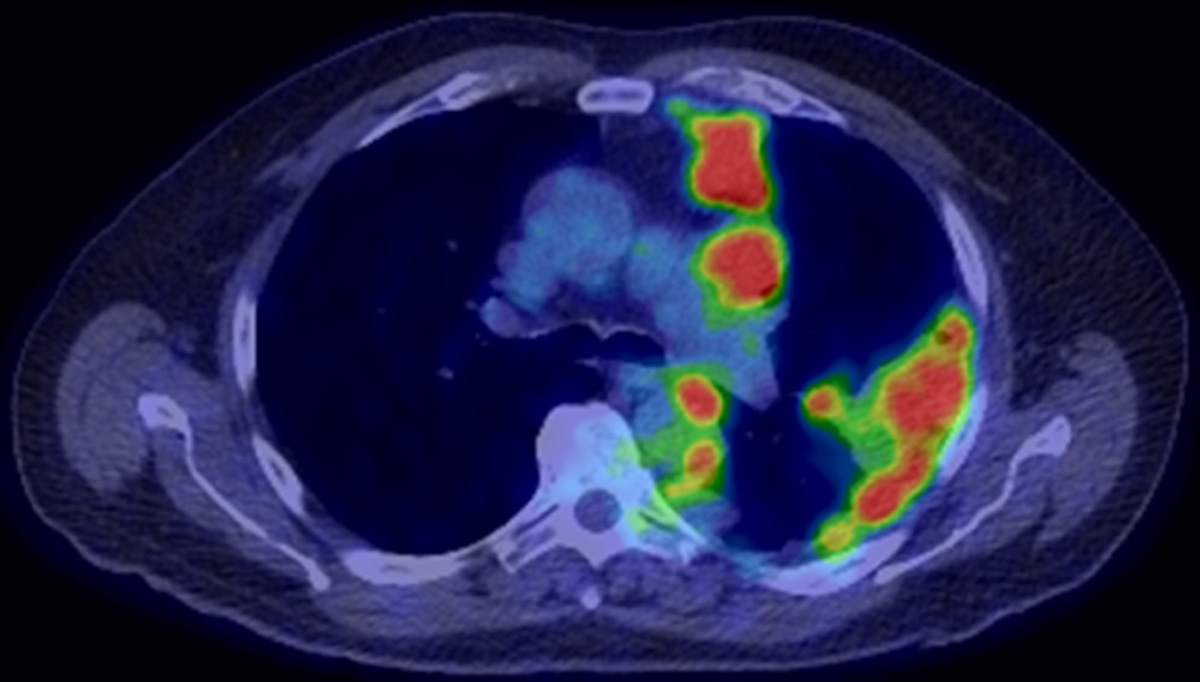

- Radiochemistry, Radioisotopes, Radiopharmaceuticals, Experimental use, Nuclear medicine, Pharmaceuticals

- End products

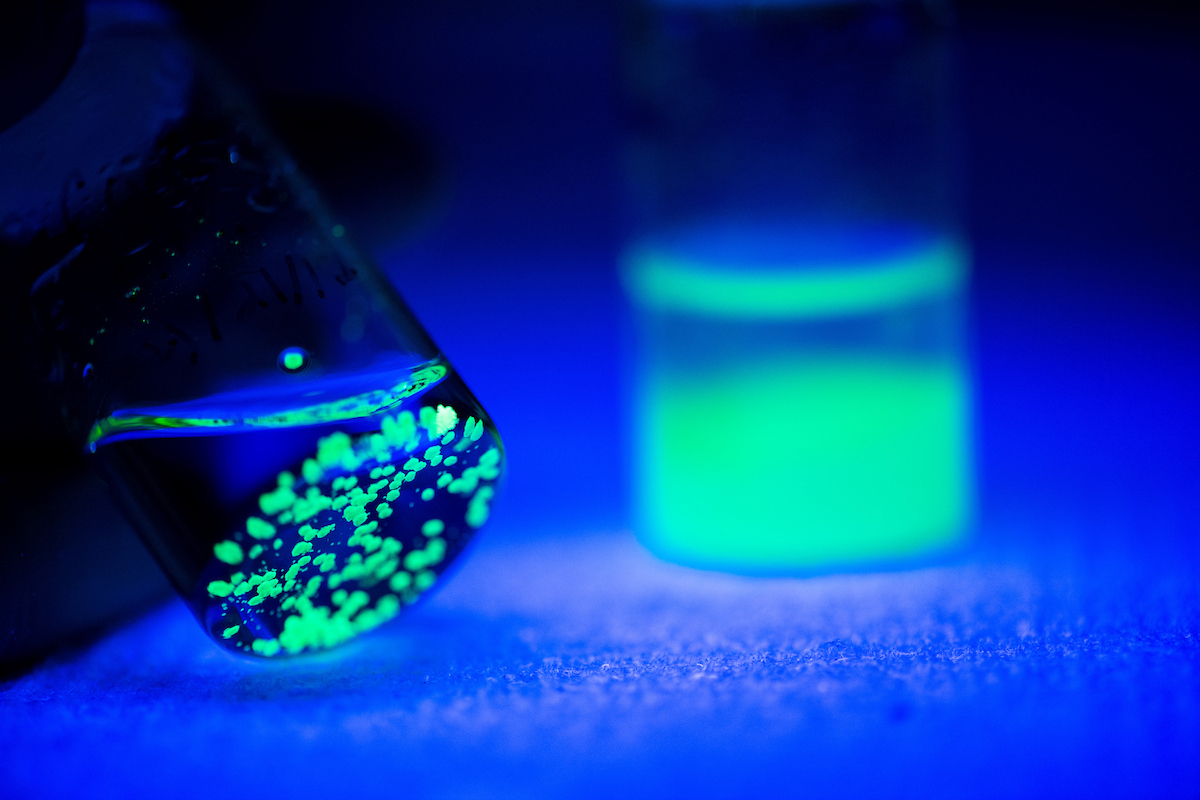

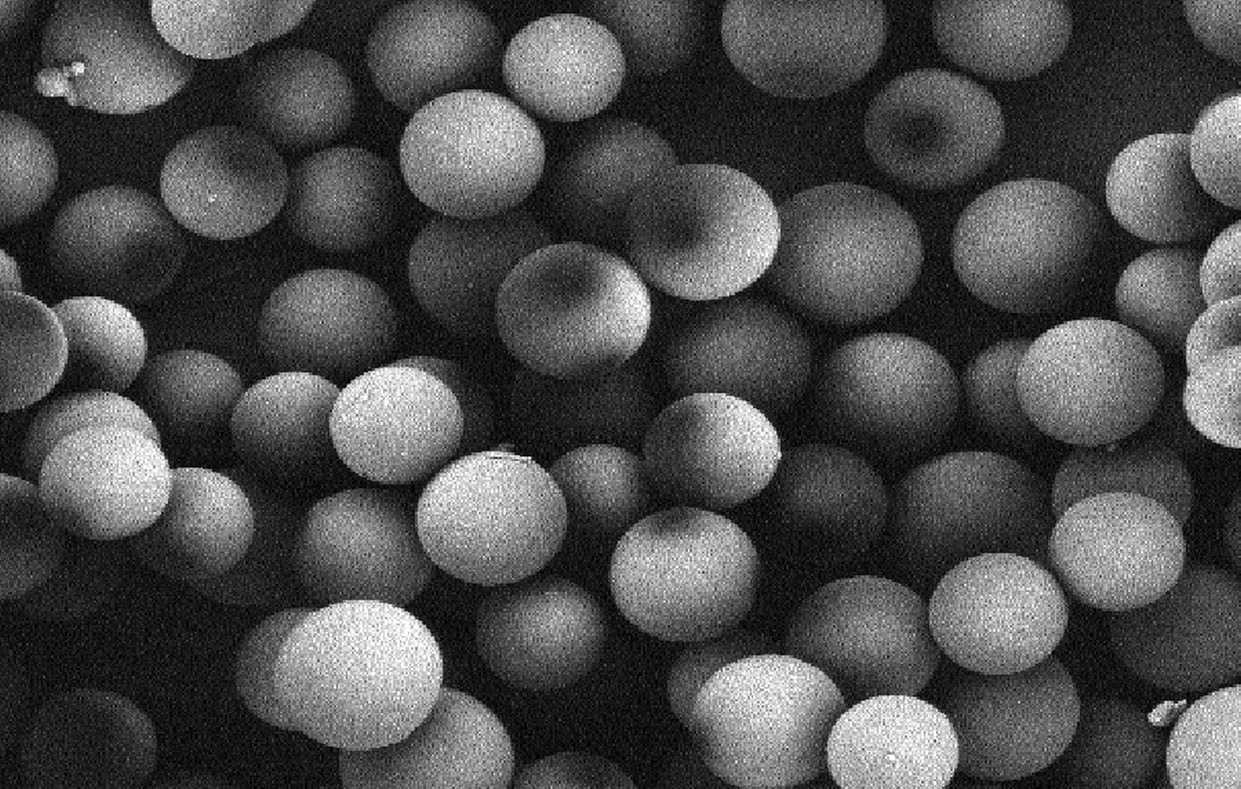

- Thallium-201, Iodine-123, Carbon-11, Samarium-153 lexidronam, Iodine-131, Technetium-99m, Gallium-68 dotatate, Fluorodeoxyglucose (fdg), Lutetium-177 therapy doses, Yttrium-90 microspheres

- Steps before

- Installation, Calibration, Loading Synthesis Modules, Setup Tele-Manipulators

- Steps after

- Product Extraction, Dose Calibration, Sterilization, Decontamination

- Input ingredients

- radioisotopes, radiopharmaceuticals, automatic synthesis modules, complex equipment, HPLC, radioactive fluids

- Output ingredients

- calibrated isotope vials, synethsized radiopharmaceuticals, decontaminated chamber air, extracted vials

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Shielding Thickness

- 75 mm or 100 mm

- Operator Panel

- 7” touch-screen

- Air Quality Class

- Class B "At rest" (EEC-cGMP)

- Material for Fluid Supply Lines

- AISI 316L stainless steel

- Sealing Type

- Inflatable gaskets

- Vial Extraction System

- Comecer Drawing System

- Door Type

- Hinged/Sliding with shielded glass

- Automation

- Real-time machine performance data with Illuminate™

- Ventilation

- Turbulent flow, continuous negative pressure

- Tele-manipulators

- Prepped for installation

- Automatic Leak Test

- Set-up available

- Material Transfer Tray

- Available

- Air Inlet Filtration System

- HEPA absolute filtering cartridge (99.995% efficiency)

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- cGMP, EEC-cGMP Class B

- ISO 9001

- Certified Quality System

- ISO 13485

- Certified Quality System

- ISO 45001

- Health and Safety Management System

- ISO 14001

- Environmental Management System

- ISO 50001

- Energy Management System

- Machine footprint

- 1100 mm or 1390 mm

- Shielding thickness

- 75 mm / 100 mm lead

- Control panel type

- 7” touch-screen operator panel

- Work chamber

- Sealed and shielded

- Door type

- Hinged or sliding with large shielded glass

- Material

- AISI 316L stainless steel

- Surface finishing

- Mirror-Bright

- Ventilation

- Continuous negative pressure

- Inflatable gasket system

- Door perimeter sealing

- Technical lower compartment

- Electrical sockets and cable entry

- Product extraction system

- Airlock system with double valve separation

- Material transfer tray

- Sliding shielded protection

- Size Options

- Modular design and flexible configuration

- Control panel type

- 7” touch-screen operator panel

- Shielding options

- Pb 75 or 100 mm

- Modular design

- Yes, with flexible configuration

- Chamber size

- 1100 mm and 1390 mm (work chamber width)

- Material transfer method

- Material transfer tray, sliding shielded protection

- Manipulation options

- Telepliers, tele-manipulators

- Automation options

- IIoT manufacturing intelligence platform

- Extraction system

- Product extraction system with shielded container

- Door type

- Hinged or sliding front door with large shielded glass

- Inflatable gasket system

- Yes, for perfect door closing and chamber sealing

- Geiger probe set-up

- For radioactivity measurement

- Contaminated air containment

- Set-up for ACS

- Leak test

- Set-up for automatic leak test