Shielded isolator for radiopharmaceutical synthesis and dispensing

Ensure radiopharmaceutical purity and operator safety with advanced barrier technology, facilitating seamless synthesis and precise aseptic dispensing in one integrated environment.

Synthesizes and Dispenses Radiopharmaceuticals Safely

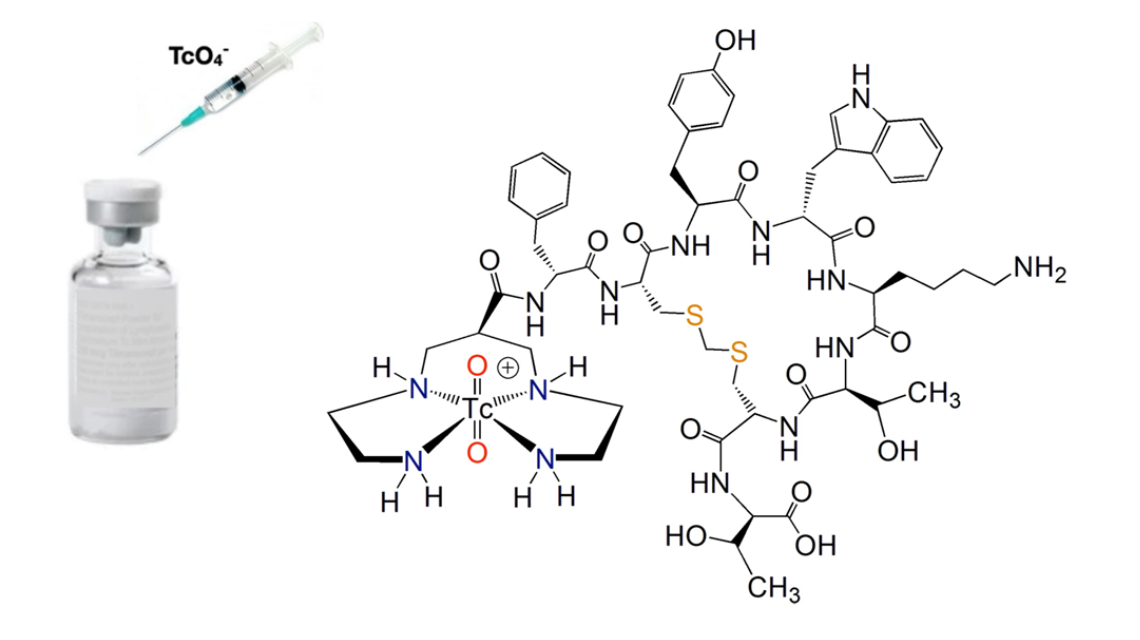

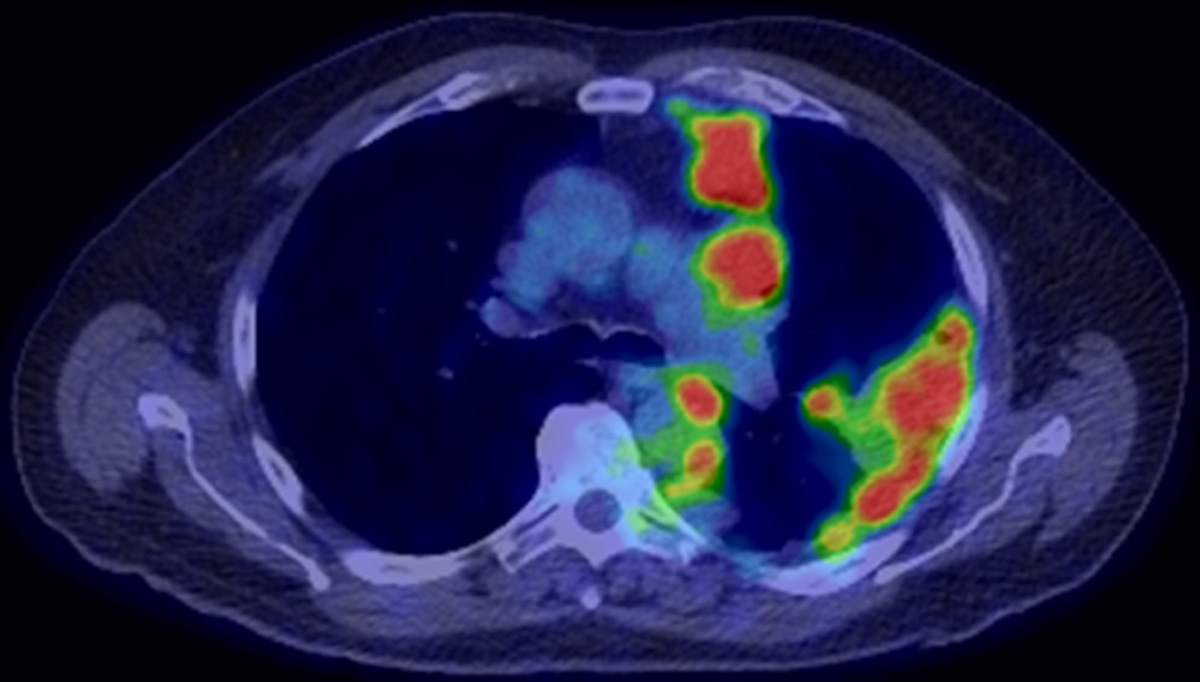

The PHAEDRA COMBO Series from Comecer is a versatile shielded isolator specifically designed for the synthesis and dispensing of radiopharmaceuticals and aseptic pharmaceutical products. What sets this equipment apart is its combination of modular design and strict adherence to cGMP standards. The system seamlessly integrates a synthesis and dispensing chamber, allowing for precise production and containment of various isotopes such as FDG, Iodine-123, and more. With a synthesis capacity maintained under Class B conditions and dispensing under Class A laminar airflow, it ensures the highest purity levels. The isolator’s compact design is ideal for small laboratory spaces, while its ergonomic features and the tele-plier handling system provide safe, efficient operations. Certified with advanced decontamination features and designed for ease of cleaning, the PHAEDRA COMBO Series offers a reliable solution for pharmaceutical manufacturers, nuclear medicine facilities, and hospital pharmacies seeking state-of-the-art radioprotection and operational excellence.

Benefits

- Enhances operational safety with comprehensive radioprotection and contamination control.

- Optimizes space efficiency with compact, modular design suitable for small labs.

- Ensures compliance with cGMP standards, minimizing risk in pharmaceutical production.

- Improves product quality through precise Class A and B air quality maintenance.

- Increases adaptability with configurable operation modes to fit specific production needs.

- Applications

- Nuclear medicine, Radiochemistry, Radiopharmaceuticals, Aseptic pharmaceutical dispensing

- End products

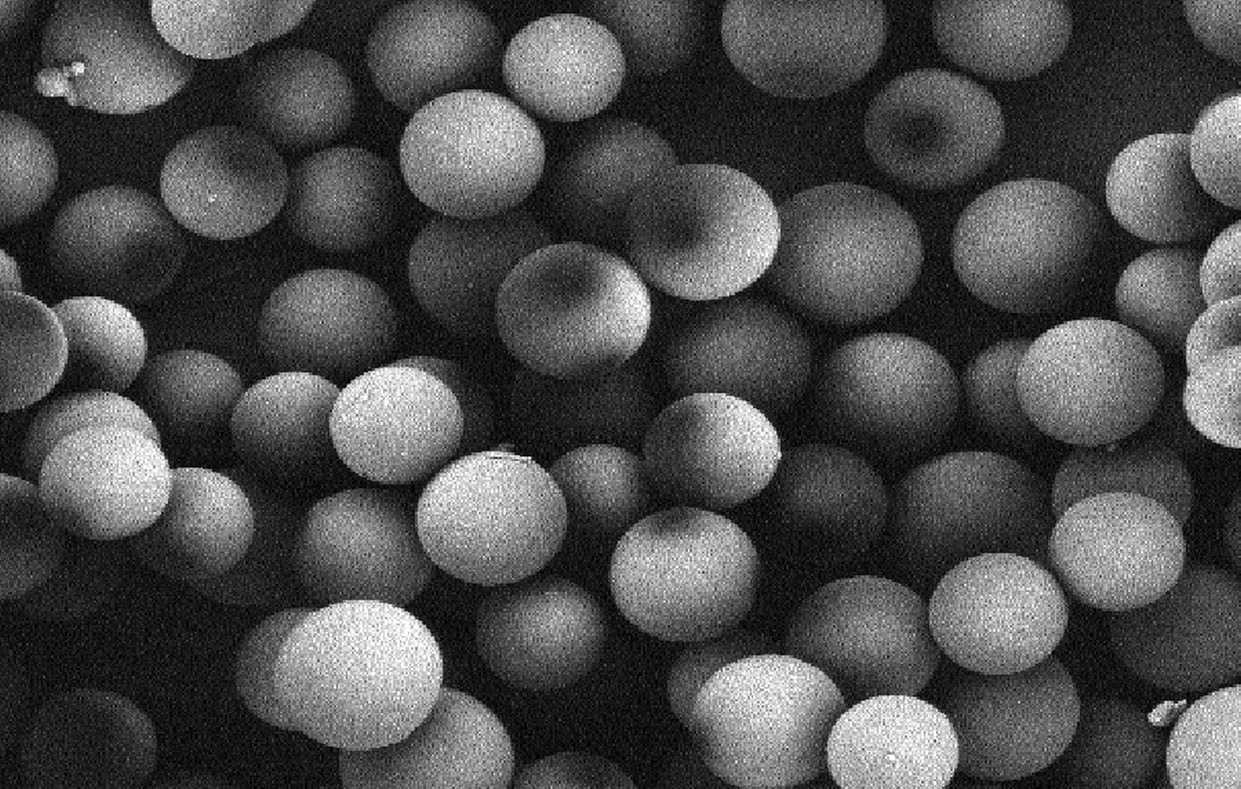

- Iodine-123 radiotracers, Aseptic filled syringes, Iodine-131 therapy doses, Technetium-99m radiopharmaceuticals, Sterile vial dispensing, Lutetium-177 therapeutic doses, Gallium-68 pet tracers, Fluorodeoxyglucose (fdg), Molybdenum-99/technetium-99m generators, Yttrium-90 microspheres

- Steps before

- Radiopharmaceutical synthesis, Material preparation, Calibration, Pre-chamber material input

- Steps after

- Sterilization, Decontamination, Quality control, Packaging, Dose calibration

- Input ingredients

- synthesis modules, materials for radiopharmaceutical production, vials, syringes, destructive waste

- Output ingredients

- radiopharmaceuticals, dispensed vials, dispensed syringes

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Compliance

- cGMP regulations

- Air Quality

- Class A LAF (Laminar Air Flow)

- Air Quality

- Class B pre-chamber

- Modular Design

- Flexible Configuration

- Automation

- Touch-screen Operator Panel

- Shielding

- 75 mm lead

- Material

- 316L AISI stainless steel

- Material

- 304 AISI stainless steel

- Filtration System

- ULPA U15 and HEPA H14 cartridges

- Pressure

- Constant Negative or Positive (upon request)

- Ergonomics

- Combination of gloves and tele-pliers

- Pass-through Capillary

- Airtight Shielded

- Dose Calibrator

- 2 Ci or 20 Ci versions

- Tele-plier System

- "QuickPlug" Technology

- Automation level

- Manual / PLC / Touch-screen

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Yes

- Cleaning method

- Manual / CIP compatible

- Changeover time

- Quick changeover with QuickPlug system

- Airflow control

- Laminar flow with ULPA filtration

- Material transfer

- Pre-chamber for material input

- Decontamination

- Effective decontamination procedures

- Ergonomics

- Ergonomic design with tele-pliers

- Cleanability

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Synthesis module compatibility

- Hermetically sealed

- Control panel type

- 12” touch-screen operator panel

- Discharge method

- Tele-pliers with “QuickPlug” system/platform for vial and syringe extraction

- Material of construction

- 316L AISI stainless steel work chambers

- Material of construction

- 304 AISI stainless steel front coverings

- Machine footprint

- Modular design and flexible configuration

- Waste compartment

- Class B air quality

- Gloves pre-chamber

- Class B air quality

- Synthesis chamber

- Up to Class B air quality

- Dispensing chamber

- Class A air quality with laminar flow

- Shielded door

- 75 mm lead shielding

- Control panel type

- 12” touch-screen operator panel

- Tele-pliers system

- QuickPlug system for tight release

- Pressure settings

- Constant negative or positive pressure (upon request)

- Vial and syringe extraction

- Transport shielded container with pass-through dose calibrator

- Airtight shielded inlets

- Radio-fluid airtight shielded inlets in synthesis and dispensing chambers

- Shielded chamber configuration

- Modular design and flexible configuration

- Negative pressure maintenance

- Hermetically sealed and maintained in negative pressure

- Gloves pre-chamber

- Class B air quality