Nested fillers for vials, pre-filled syringes, and cartridges

Optimize your aseptic filling processes with precision dosing and multi-format capabilities, ensuring contamination-free environments for high-value biopharmaceutical and injectable product lines.

Fills, Seals, and Stoppers Vials, Syringes, and Cartridges

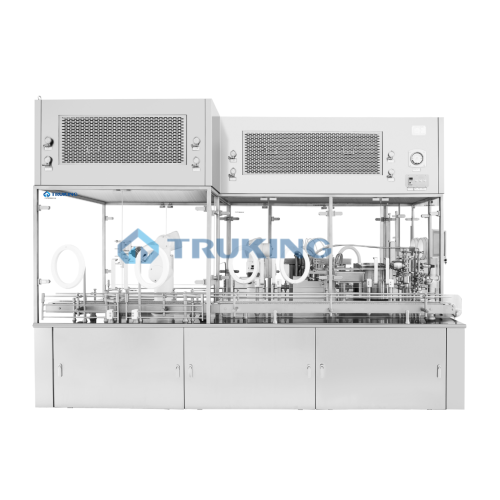

The TRUKING Flextron Series Nest Fillers are designed to meet the diverse challenges faced by modern pharmaceutical manufacturers. This equipment facilitates the seamless filling, sealing, and stoppering of vials, pre-filled syringes, and cartridges. Utilizing a fully servo-controlled and robotic design, it ensures high throughput with minimal breakage, processing up to 36,000 units per hour. Its versatility enables handling multiple formats in a single unit, optimizing efficiency across various formulations including biologics and IV solutions.

Automation is enhanced with features like automatic de-bagging and vacuum stoppering, promising precise and bubble-free end products. The system offers in-house OEL 5 containment within custom C-RABS and Isolators for maximum safety and compliance with stringent GAMP, cGMP, and FDA standards. An industrial PC controls operations, ensuring comprehensive data integrity and remote access.

Construction incorporates superior SS 316L for product contact parts, enabling effective cleaning with built-in CIP & SIP systems. Customizable footprints and modular designs are available to fit specific cleanroom requirements, providing an ideal solution for biopharmaceutical applications, including insulin and vaccine production. The TRUKING Flextron Series does more than fill—it integrates performance with compliance, efficiency with precision.

Benefits

- Enhances productivity with high-speed operation of up to 36,000 units per hour.

- Minimizes contamination risk with integrated OEL 5 containment and custom isolation solutions.

- Reduces operational costs through versatile format handling in a single unit.

- Ensures compliance and data integrity with 21CFR Part 11 compliant control systems.

- Optimizes space usage with compact, modular design tailored to cleanroom requirements.

- Applications

- Injectable products, Biopharmaceuticals, Traditional chinese medicine, Oral liquid formulations, Diagnostic reagents, Pharmaceuticals

- End products

- Biologics, Vaccines, Insulin, Monoclonal antibodies, Diagnostic test kits, Herbal extracts, Tablets, Syrups, Iv solutions, Essential oils

- Steps before

- Preparation System, Bioreactor System, Extraction, Concentration, Purification and Separation

- Steps after

- Leakage Testing, Inspection, Secondary Packaging, Sterilization, Washing

- Input ingredients

- Vials, PFS (Pre-Filled Syringes), Cartridges, Nested packaging, Liquid medications, Oral liquids, Lyophilization materials, Diagnostic reagents

- Output ingredients

- Filled vials, Filled PFS, Filled cartridges, Bubble-free products, Ready-to-use applications, Premium filled products

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Capacity

- 36, 000 units/hour

- Automation

- Fully automatic, semi-automatic, and manual operation

- Accuracy

- ±0.5% - ±1%

- Material

- SS 316L product contact design

- CIP/SIP

- Online CIP, SIP function

- Dosing System

- Volumetric to Peristaltic pumps

- Containment Level

- OEL 5

- Footprint Design

- Compact with modular customization

- Control System

- Industrial PC control complying with 21CFR Part 11

- Automation level

- Fully Servo and Robotic

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- Online CIP, SIP function

- Cleaning method

- CIP / Manual

- Changeover time

- Minimal due to modular customization

- Energy efficiency

- Highly efficient, reduces floor plan dependency

- Working mechanism

- Automatic de-bagging, Auto Tyvek removal

- Integrated steps

- Debagging, sealing, stoppering in one system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bubble Free Product

- Vacuum stoppering

- Compact footprint

- Yes

- Machine footprint

- Modular design

- Control panel type

- Industrial PC

- Discharge method

- Automatic seal paper removal

- Control panel type

- Industrial PC

- Integration possibilities

- O-RABS, C-RABS, Isolators

- Footprint design

- Compact modular customization

- Operation units

- Fully automatic, semi-automatic, manual

- Product contact design material

- SS 316L