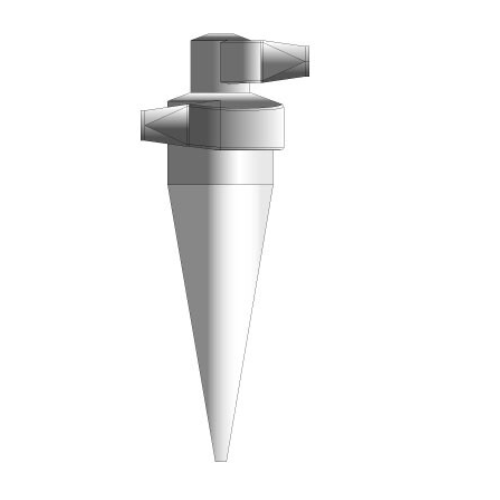

Industrial cyclone separators for air particulate removal

Optimize particulate removal in air streams with cyclone separators, utilizing vortex separation and gravity to efficiently separate solids and air, enhancing production purity and reducing filter dependency.

Effectively Separates Particulates from Air Streams

The Anhydro Cyclone Separator is an engineered solution designed for efficient particle removal across various industries, including food, dairy, and beverage processing. It operates using a vortex separation method, leveraging rotational effects and gravity to separate solids from air streams without filters. This equipment is capable of handling a range of particulate loads, making it suitable for producing infant formula powder, protein-enriched milk, and plant-based protein powders. Installation options vary from single to multiple configurations, with facilities for fines return to the top of the chamber or external fluid beds.

The Cyclone Separator can be integrated into continuous, high-speed operations with its adaptable configurations. It ensures energy-efficient separation processes, and options include outlet stiffeners for structural integrity, explosion vents for safety, and CIP (Clean-in-Place) systems for hygienic maintenance. Built from robust materials, it supports operational demands and regulatory compliance, making it a reliable choice for companies seeking precise and consistent particulate separation in their production lines.

Benefits

- Enhances product purity by efficiently removing particulates from air streams.

- Supports versatile production needs with flexible installation configurations.

- Minimizes energy use by utilizing gravity and rotational effects instead of filters.

- Reduces safety risks with optional explosion vents and suppression systems.

- Maintains rigorous hygiene standards through effective CIP integration.

- Applications

- Permeate, Beverage processing, Pet food, Plant-based drinks and food, Skim milk, Dairy powders, Food processing, Dairy processing, Whey, Baby food, Whole milk

- End products

- Vegetable-based drink powders, Pet nutritional supplement powders, Powdered milk formulas, Lactose-free milk powder, Protein-enriched milk powder, Dairy permeate powder, Whey protein concentrate, Infant formula powder, Whey protein isolate, Plant-based protein powders

- Steps before

- Spray Drying, Mixing, Blending, Filtration, Deaeration

- Steps after

- Powder Handling, Packing, Storage, Dosing, Transport

- Input ingredients

- air stream, particulates, mixtures of solids and air

- Output ingredients

- air, solids, fine particulates, powder, baby food powder, skim milk powder, whole milk powder, whey powder, permeate powder

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Configuration

- Single, Double, Multiple

- Powder Loss

- Approx. 90-280 mg/Nm³

- Explosion Safety

- Explosion vents or suppression bottles

- CIP Capability

- CIP'able with required nozzles

- Inlet/Outlet Reinforcement

- Stiffeners installed as per size

- Fines Return Locations

- Top of chamber, external fluid bed

- Working mechanism

- Vortex separation

- Integrated steps

- Particulate removal

- CIP principles

- CIP'able with nozzles

- Batch vs. continuous operation

- Continuous

- Powder loss range

- 90-280 mg/Nm3

- Safety features

- Explosion vents/suppression bottles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Configuration

- Single, Double, Multiple

- Return location

- Top of chamber, External fluid bed

- Inlet/Outlet Stiffeners

- Yes, depending on size

- Configuration

- Single, Double, Multiple

- Fines return location

- Multiple locations (Top of chamber, To external fluid bed)

- Explosion protection

- Explosion vents or suppression bottles

- CIP Capability

- CIP'able with required CIP-nozzles

- Structural support

- Inlet and outlet stiffeners

- Additional Features

- Welded Suppression Bottles, CIP Ring Pipe and Spray Balls/Nozzles