Radiopharmaceutical dispensing isolator for vials and syringes

For precise radiopharmaceutical preparation, this isolator offers safe, calibrated dispensing of both vials and syringes, ensuring contaminant-free operations in high-stakes environments like nuclear medicine and pharmaceuticals.

Dispenses and Calibrates Radiopharmaceuticals Safely

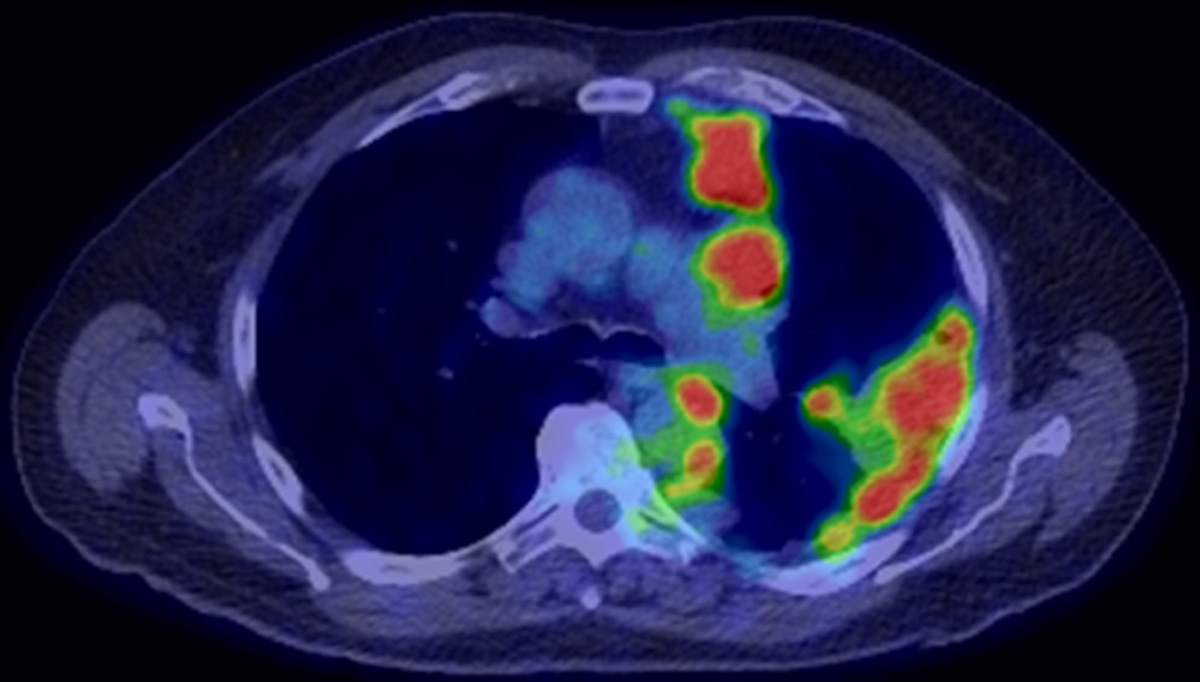

The Radiopharmaceutical Dispensing Isolator PHAEDRA from Comecer offers a specialized solution for handling and dispensing sensitive radiopharmaceutical compounds. PHAEDRA stands out for its dual-stage dispensing and calibration system that maintains sterility and safety, making it ideal for producing Fluorodeoxyglucose (FDG), Gallium-68 radiotracers, and more. Equipped with a Class A chamber, it supports a laminar flow environment crucial for contamination control. This isolator is optimized for batch and continuous operations, featuring both manual and high-speed processes. Integration with GMP lines is seamless, with a user-friendly touch panel for precise control. Fabricated with 316L stainless steel, it offers excellent corrosion resistance, catering to the demanding environments of nuclear medicine and pharmaceutical compounding. Fully compliant with GMP standards, PHAEDRA ensures minimal downtime through its efficient waste management and swift decontamination capabilities, including an optional VPHP system for thorough sterilization. Whether you’re in medical research or a hospital pharmacy, PHAEDRA provides comprehensive solutions for radiopharmaceutical applications.

Benefits

- Enhances operational safety and sterility with Class A chamber conditions.

- Minimizes downtime through efficient waste management and rapid decontamination systems.

- Supports diverse radiopharmaceutical production with interchangeable vial and syringe formats.

- Offers flexibility in manual and automated dispensing processes, suited for high-speed operations.

- Maintains regulatory compliance with GMP standards across production processes.

- Applications

- Nuclear medicine products, Pharmaceutical compounds, Radiopharmaceuticals

- End products

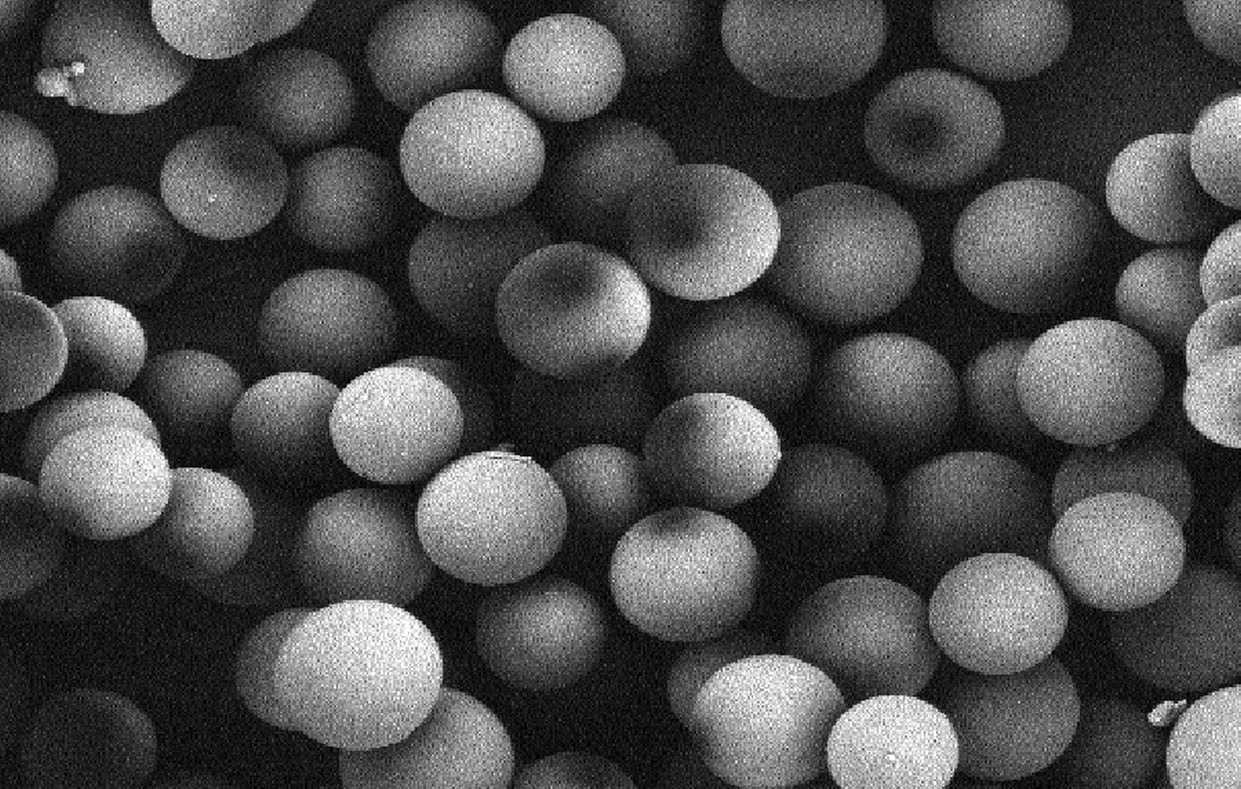

- Carbon-11 injections, Technetium-99m labeled compounds, Lutetium-177 solutions, Indium-111 vials, Gallium-68 radiotracers, Fluorodeoxyglucose (fdg), Iodine-131 capsules, Yttrium-90 microspheres

- Steps before

- Preparation, Loading vials, Loading syringes, Aseptic area preparation

- Steps after

- Cleaning, Decontamination, Consumable removal, Packaging, Label printing

- Input ingredients

- vials, syringes, disposable items, radioactive fluids

- Output ingredients

- filled vials, filled syringes, solid waste

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Chamber Classification

- Class A, B (EEC-cGMP)

- Shielding

- 75 mm lead

- Main Chamber Dimensions

- 175 cm wide

- Capacity

- 20 vials (15 ml each)

- Automation

- Touch screen interface

- Temperature,Humidity Sensors

- Yes

- Tele-pliers

- QuickPlug system

- Ventilation System

- Automatic tightness tests

- Waste Compartment Classification

- Class B (EEC-cGMP)

- Material

- 304, 316L AISI Stainless Steel

- Work Chamber Surface Finish

- Mirror-Bright

- Laminar Flow

- Full-area laminar flow

- Hydrogen Peroxide Decontamination

- VPHP integration

- Control System

- CFR21 PART 11

- Filtration System

- Particle monitoring available

- Automation level

- Manual / PLC / IIoT platform

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP / Manual

- Ergonomics

- High operation ease

- Flexibility

- Vials and syringes extraction system

- Safety features

- Lead shielding

- Emergency handling

- Safe pharmaceutical recovery

- User interface

- Touch screen

- Machine footprint

- 175 cm width

- Front door

- Shielded and hinged equipped with glass and hand doors

- Lead shielding

- 75 mm

- Work chamber material

- 316L AISI stainless steel

- Front covering material

- 304 AISI stainless steel

- Touch screen size

- 15” operator panel

- Internal surface finish

- Mirror-Bright with TIG continuous welds

- Control panel type

- 15” touch-screen operator panel

- Integration Possibilities

- Integration with IIoT platform Illuminate™ MI

- Tele-pliers System

- QuickPlug for rapid and airtight release

- Extraction System

- Universal extraction system for vials and syringes

- Compatibility

- Compatible with Comecer Radiopharmaceutical Dispensers

- Label Printing Integration

- E-LABEL system for GMP compliance