Ventilated pass-through for classified environment transition

Ensure sterile and secure transfer between environments with this ventilated pass-through, featuring interlocked doors and HEPA filtration, ideal for maintaining cleanliness and containment in critical processing areas.

Controls Airflow and Material Transfer

The BU-IV Ventilated Pass-through with Interlocked Doors from Comecer is designed for environments demanding stringent contamination control, such as radiopharmaceutical, nuclear medicine, and pharmaceutical settings. This equipment specializes in maintaining pure airflow during material transfers between areas, utilizing a HEPA filter and positive pressure system to ensure containment. The interlocked doors prevent simultaneous opening, safeguarding the classified environments from potential exposure. Capable of handling both solid and gas products, the BU-IV boasts manual and continuous operation modes, ideal for processes like filtration, ventilation, and decontamination. Its stainless steel construction, welded through the TIG method, ensures resistance to corrosion and facilitates thorough cleaning. Furthermore, the system integrates seamlessly into existing production lines, allowing easy integration with minimal disruption. Designed to meet GMP standards, it ensures the safety of both personnel and sensitive materials. Customization options are available to fit specific industrial needs, supported by comprehensive engineering support.

Benefits

- Enhances contamination control with HEPA filtration and positive pressure.

- Protects personnel with shielding that limits exposure risks.

- Maintains operational integrity even in power loss scenarios.

- Simplifies cleaning with corrosion-resistant stainless steel design.

- Ensures compliance with GMP standards for pharmaceutical applications.

- Applications

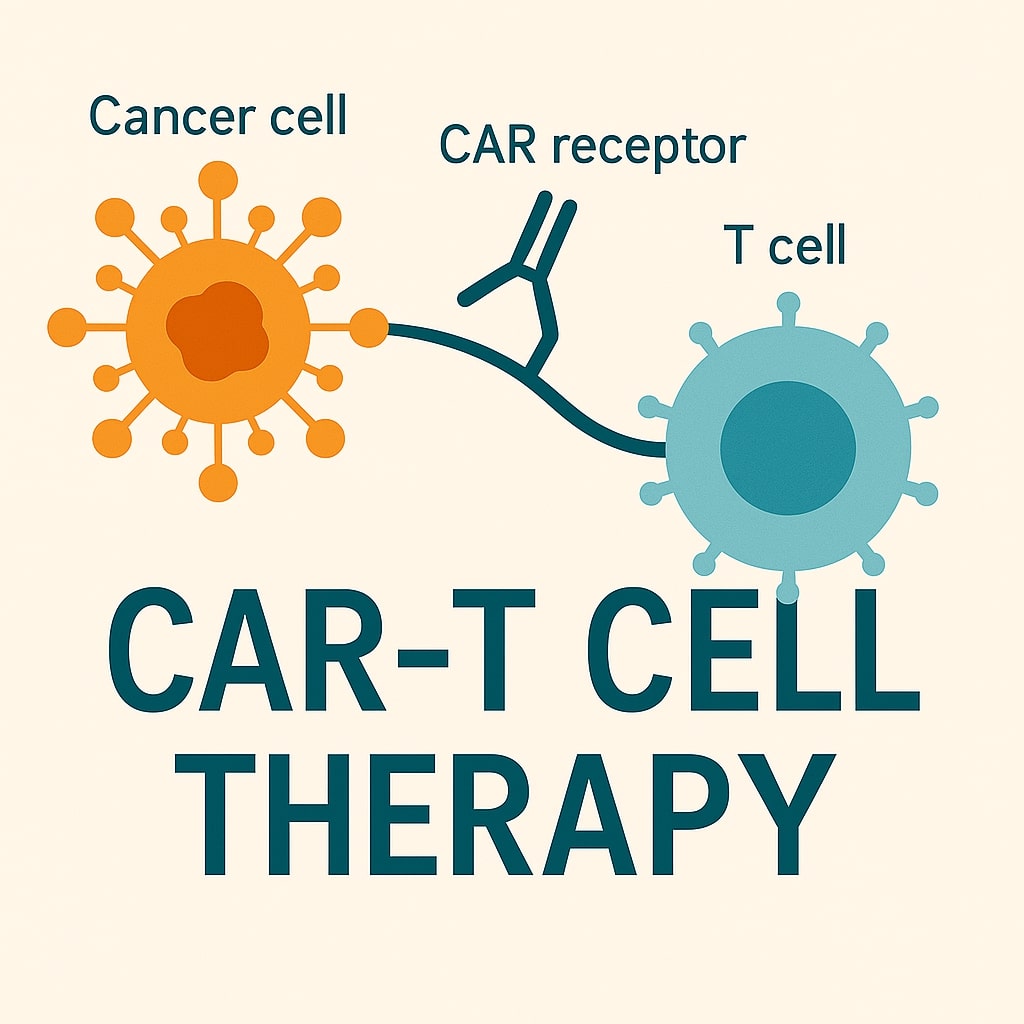

- Containment, Cell, Radiopharmaceuticals, Gene therapy, Atmp (advanced therapy medicinal products), Aseptic processing, Hospital pharmacy, Nuclear medicine, Pharmaceuticals

- End products

- Sterile injectable drugs, Car-t cell therapies, Compounded sterile preparations, Monoclonal antibodies, Radioactive tracers, Gene therapy viral vectors, Fdg (fludeoxyglucose), Cytotoxic drug containment solutions

- Steps before

- Decontamination, Quality Control

- Steps after

- Material Transfer, Exposure Prevention

- Input ingredients

- materials, external air

- Output ingredients

- materials, filtered air

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Ventilation

- Positive pressure

- HEPA Filter

- Yes

- Material

- Stainless Steel

- Shielding

- Lead 10 mm

- Welding Method

- TIG

- Pressure Maintenance

- Positive Pressure

- Working mechanism

- Interlocked door system

- Pressure control

- Positive pressure compared to hot chamber and exterior

- Filtration

- HEPA filter in passthrough

- Door locking system

- Inflatable gaskets

- Emergency opening capability

- Manual valve

- Material protection

- Pb 10 mm shielding for radiation protection

- Air exchange method

- Switching air between closures

- Power failure safety

- Maintained door position without power

- Material decontamination

- Complete decontamination capability

- Exposure risk prevention

- Protection from exposure in hot chamber

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Passthrough usage

- Hot Chamber to Quality Control

- ISO 9001,ISO 13485

- Certified Quality System

- ISO 45001

- Health and Safety Management System

- ISO 14001,ISO 50001

- Environmental and energetic management system

- Material of construction

- Stainless steel

- Door type

- Interlocked

- Shielding material

- Lead (Pb) 10 mm

- Welding method

- TIG welding

- Surface finish

- Ground and polished

- Gasket sealing

- Inflatable gaskets

- Control panel type

- Manual valve for emergency opening

- Door sealing

- Inflatable gaskets

- Material

- Stainless steel components