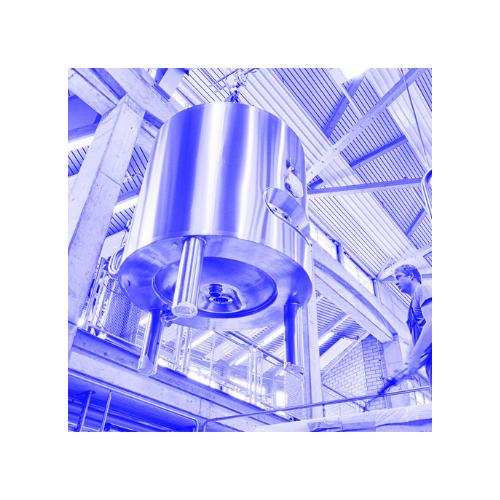

Sterile media and buffer storage tanks

Ensure uninterrupted bioproduction with our tanks designed for secure storage and precise dosing of sterile media and buffers, maintaining sterile conditions for critical upstream and downstream processes.

Stores, Transfers, and Sterilizes Sterile Media and Buffers

Bioengineering’s Media and Buffer Hold Tanks are integral components in biopharmaceutical production, specifically designed to support seamless operations in biotech processes. What sets these stainless steel tanks apart is their ability to securely store, transfer, and sterilize media and buffers essential for cell culture and microbial processes. Ideal for applications involving vaccines, monoclonal antibodies, and recombinant proteins, they streamline production by integrating into both fed-batch and continuous processes. These tanks range from 30 to 20,000 liters and provide options for manual or fully automated operation, featuring hygienic control valves and sterile filtration systems. The tanks can be automated to integrate into CIP systems, ensuring efficient cleaning and maintenance. Constructed from corrosion-resistant stainless steel, they comply with global GMP standards, ensuring safety and reliability in biopharmaceutical environments. Additionally, Bioengineering offers customization and engineering support to match your specific production requirements.

Benefits

- Ensures seamless production flow by integrating storage, sterilization, and transfer processes.

- Minimizes contamination risk with fully automated CIP integration.

- Enhances operational efficiency with precise dosing and transfer capabilities.

- Complies with GMP standards, ensuring compliance in regulated environments.

- Offers flexible scalability to adapt to evolving production demands in biotech and biopharma sectors.

- Applications

- Cell culture, Biopharmaceuticals, Microbial processes, Buffers, Sterile media, Biotech production

- End products

- Gene therapy products, Vaccines, Chromatography buffers, Insulin, Cytokines, Monoclonal antibodies, Serum-free media, Enzymes, Growth factors, Recombinant proteins, Cell growth media

- Steps before

- Media Preparation, Sterilization, Sterile Filtration

- Steps after

- Sterile Dosing, Transfer to Bioreactor, CIP (Clean-In-Place)

- Input ingredients

- sterile media, corrective agents, buffers, microbial processes, cell culture

- Output ingredients

- sterile solutions, fed-batch processes, continuous processes, pH control, anti-foam control, buffer for purification

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Capacity

- 30 to 20, 000 liters

- Material

- Stainless steel

- Sterilization

- Heat-resistant / Sterile filtered

- Automation

- Fully automated / Manual

- Control

- Hygienic control valves

- Pump/Transfer System

- Pump or pressure systems

- Dosing

- Exact dosing concepts

- Integration

- CIP system integration

- Vessel Sizes

- 0.5 to 10 liters (glass), 10 to 50 liters (autoclavable)

- Media Handling

- Heat-instable / Sterile filtered

- Process Type

- Fed-batch or continuous

- Temperature Resistance

- Heat-resistant media sterilizable

- Control Level

- Transfers, feeds, sterilization automation

- Feed Strategies

- Various culture technologies

- Working mechanism

- Sterilization, Heat-resistant, Sterile filtration

- Integrated steps

- Preparation, Transfer, Storage

- CIP principles

- Integrated into CIP system

- Batch vs. continuous operation

- Fed-batch or continuous processes

- Control system

- BioSCADA

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Stainless Steel Standards

- AISI 316L/304

- Tank shape

- Stirred

- Tank size

- 30 to 20, 000 liters

- Container size

- 0.5 to 10 liters

- Material

- Stainless-steel

- Sterilization method

- Heat-resistant / Sterile filtered

- Transfer method

- Pump / Pressure system

- Control panel type

- Intuitive HMI

- Integration possibilities

- Automated systems integrated into production line

- Dosing control

- Hygienic control valves or pulsing valves

- Automation level

- Fully automated storage systems

- Sterilization options

- Heat-resistant media direct sterilization

- Sterilization options

- Sterile filtering for heat-instable media

- Storage tank variance

- Simple stirred tanks to automated systems

- Transfer system

- Pump or pressure systems

- Capacity range

- 30 to 20, 000 liters

- Capacity range

- Autoclavable containers 10 to 50 liters

- Manual to automated systems

- Manually operated vessels to fully automated storage systems