Six stage r&d isolator for safe material handling

Ensure optimal operator safety and material containment during complex syntheses with this advanced research and development isolator, featuring six isolated chambers and intelligent control systems designed for seamless integration into your laboratory environment.

Isolates and Synthesizes Radiopharmaceutical Compounds

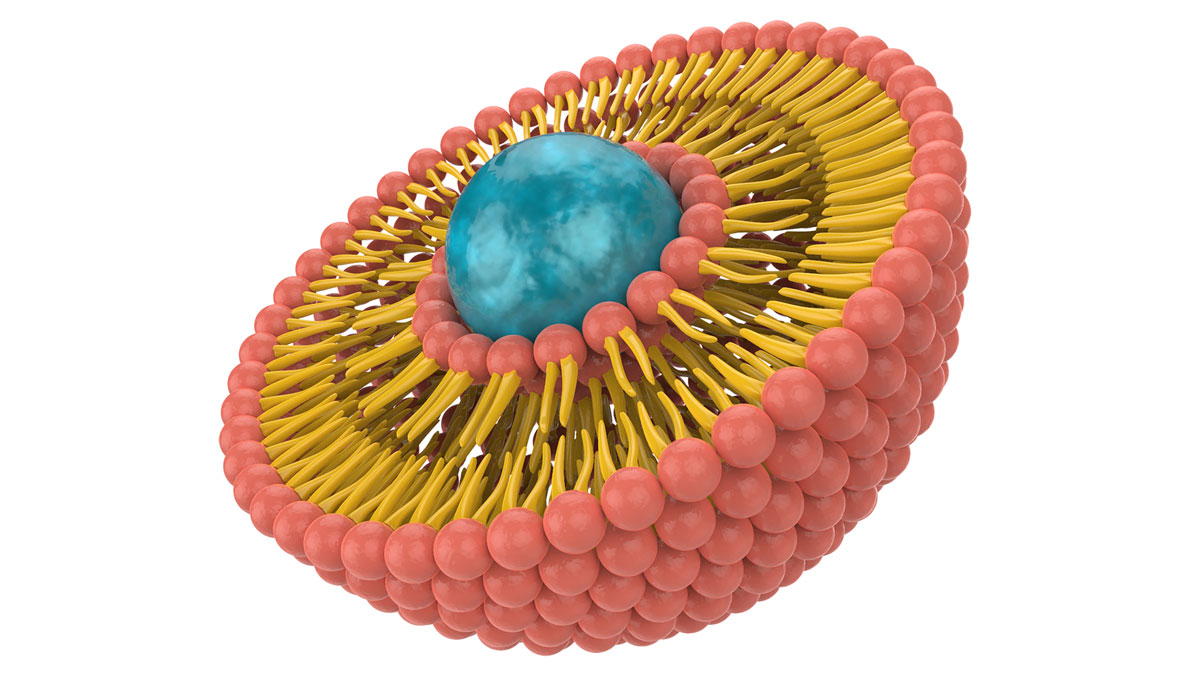

The Six Stage Research and Development (R&D) Isolator by Comecer is a sophisticated containment solution designed to enhance safety and precision in pharmaceutical and radiopharmaceutical applications. Featuring six integrated glove box chambers, this isolator facilitates complex processes like isolation, synthesis, and drying with full automation via PLC control. Its turbulent flow system with nitrogen and O2 monitoring ensures an optimal environment for working with sensitive materials such as iodine-131 capsules, technetium-99m kits, and viral vector vaccines.

Utilizing a negative pressure system relative to the laboratory environment, it guarantees the protection of operators during manufacturing and handling processes. The equipment supports a wide range of operations, including continuous and pilot-scale production, making it suitable for research & development labs and biotech companies. It includes an integrated vacuum dryer for efficient material drying and a continuous liner system for seamless material transfer.

Made from durable materials with options for corrosion-resistant finishes, the isolator meets stringent industry standards, including GMP compliance for pharmaceutical manufacturing. Additionally, a fully washable design with an integrated vacuum dryer ensures ease of cleaning to prevent cross-contamination and maintain hygienic conditions. Comecer offers customization and engineering support, allowing configurations to adapt to specific production needs.

Benefits

- Enhances safety by isolating operators from hazardous materials.

- Increases precision in synthesis tasks with fully automated, PLC-controlled operation.

- Reduces risk of contamination via a continuous liner system and washable design.

- Ensures regulatory compliance with GMP standards.

- Adapts to diverse applications from pharmaceuticals to biopharmaceuticals through customizable chamber configurations.

- Applications

- Radiochemistry, Cell, Radiopharmaceuticals, Compounding, Biopharmaceuticals, Gene therapy, Pharmaceuticals

- End products

- Personalized medicine formulations, Monoclonal antibodies, Liposomal formulations, T-cell therapies, Custom cell culture media, Technetium-99m kits, Radiolabeled compounds, Iodine-131 capsules, Viral vector vaccines

- Steps before

- Material preparation, Compound synthesis setup, Equipment calibration

- Steps after

- Drying, Quality control, Material transfer

- Input ingredients

- reactor materials, prechamber materials, synthesis materials, inlet materials

- Output ingredients

- processed materials, dried materials, synthesis products, outlet materials

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Working Areas

- 6

- Airflow Type

- Turbulent flow with nitrogen

- Oxygen Monitoring

- Available

- Pressure

- Negative pressure relative to laboratory environment

- Automation

- Fully PLC controlled

- Washability

- Fully washable

- Vacuum Dryer

- Integrated

- Internal Sliding Door

- Equipped

- Continuous Liner

- Integrated

- Working Areas

- 6 stages

- Flow Type

- Turbulent flow with nitrogen

- Oxygen Monitoring

- Yes

- Pressure Control

- Negative pressure

- Automation Level

- Fully PLC controlled

- Washability

- Fully washable

- Drying System

- Integrated vacuum dryer

- Material Handling

- Barrier sack system

- Operator Position

- Standing

- Isolation Level

- Complete operator isolation

- Chamber Functions

- Reactor, Inlet Prechamber, Synthesis, Drying, Outlet Prechamber

- Cleanability

- Fully washable

- Operator Position

- Standing position while working

- Operator Safety

- Completely isolated from the manipulated material

- ISO 9001

- Certified Quality System

- ISO 13485

- Certified Quality System

- ISO 45001

- Health and Safety Management System

- ISO 14001

- Environmental Management System

- ISO 50001

- Energetic Management System

- Number of Working Areas

- 6

- Flow Type

- Turbulent flow with nitrogen

- Pressure Type

- Negative pressure

- Control System

- PLC controlled

- Washability

- Fully washable

- Chamber Configuration

- Internal sliding door

- Vacuum System

- Integrated vacuum dryer

- Liner System

- Integrated continuous liner

- Work Position

- Standing

- Isolation

- Complete isolation for operator

- Chamber A Configuration

- Reactor with tubes to synthesis chamber

- Chamber B Configuration

- Material inlet prechamber

- Chamber C Configuration

- Synthesis 1 Chamber

- Chamber D Configuration

- Drying with vacuum dryer

- Chamber E Configuration

- Synthesis 2 with analytical balance

- Chamber F Configuration

- Material outlet prechamber with barrier sack system

- Control System

- Fully PLC controlled

- Integration Type

- Integrated vacuum dryer

- Operation Mode

- Negative pressure

- Flow Type

- Turbulent flow with nitrogen

- Chamber Design

- 6 working areas

- Sliding Door System

- Internal sliding door