Glass-lined reactor for enhanced mixing performance

Optimize your chemical processes with a reactor that enhances mixing efficiency, improves heat and mass transfer, and reduces crystallization risks, all while maintaining a high standard of cleanability and operational flexibility.

Enhances Mixing and Heat Transfer Efficiency

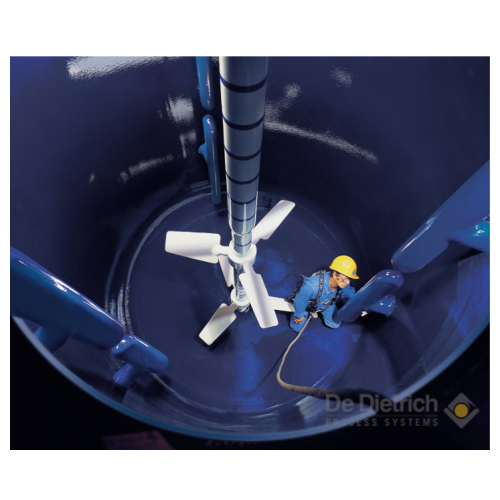

The OptiMix® reactor from De Dietrich Process Systems is a specialized glass-lined mixing reactor engineered for complex chemical processes. Its patented design integrates three baffles on the vessel wall, optimizing heat and mass transfer, gas dispersion, and suspension capabilities. Primarily used in pharmaceuticals and specialty chemical industries, it excels in producing active pharmaceutical ingredients, high-purity solvents, and specialty polymers. The reactor operates efficiently across temperatures from -30°C to 260°C and pressures up to 10 bar, supporting both batch and continuous processes.

For enhanced durability, it features a DD3009 glass lining, providing superior corrosion resistance essential for handling aggressive chemicals. The standard setup includes a GlasLock® agitator and dual coil zones, with options for further customization based on process needs. Interchangeable with standard reactors, the OptiMix reactor eliminates dead zones through its unique paddle design, ensuring easy cleaning and maintenance without crystal buildup.

Meeting industry standards for safety and efficiency, it supports seamless integration into existing production lines with full automation capabilities. The inclusion of an integrated sensor on the shell allows precise control of reaction volumes, while optional features support additional operational requirements.

Benefits

- Enhances process efficiency with optimized mixing and reduced dead zones.

- Increases operational safety and longevity with superior corrosion resistance.

- Streamlines production with free nozzles for easy system integration.

- Facilitates precise reaction control with integrated sensor technology.

- Simplifies cleaning and maintenance, minimizing downtime and contamination risks.

- Applications

- Specialty chemicals, Agricultural chemicals, Fine chemicals, Bio-pharmaceuticals, Precious metals, Pigments, Green chemistry ingredients, Pharmaceuticals

- End products

- Active pharmaceutical ingredients, Monoclonal antibodies, High-purity solvents, Gold compounds, Herbicides, Biodegradable plastics, Organic pigments, Specialty polymers

- Steps before

- Purification, Drying, Mixing, Hydrochloric Acid Treatment, Sulfuric Acid Treatment, Nitric Acid Treatment

- Steps after

- Sterilization, Distillation, Packing, Drying, Absorption, Waste Gas Treatment

- Input ingredients

- pharmaceutical ingredients, fine chemicals, reactants, solids, liquids, gases

- Output ingredients

- optimized mixture, processed pharmaceuticals, fine chemicals, suspended solids, distributed gases, crystallized products

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Capacity

- 6.3L to 25m³

- Operating Pressure

- Full vacuum to 6/10 bar

- Operating Temperature

- -30°C to 260°C

- Glass Lining

- DD3009

- Heat Transfer

- Improved baffling effect

- Mixing System

- GlasLock® agitator

- Baffle Design

- Three baffles integrated

- Reaction Volume Control

- Integrated sensor

- Cleaning Method

- Improved cleanability

- Mass Transfer

- Increased efficiency

- Coil Zones

- Two standard

- Working Mechanism

- Glass-lined steel reactor with three integrated baffles

- Automation Level

- Manual / PLC

- Batch vs. Continuous Operation

- Batch

- CIP/SIP

- Designed for easy cleaning, preventing crystal accumulation

- Cleaning Method

- Easy to clean design

- Pressure Range

- Full vacuum to 6/10 bar

- Temperature Range

- -30°C to 260°C

- Heat Transfer

- Enhanced due to optimized baffling

- Gas Dispersion

- Improved through integrated baffles

- Solids Suspension

- Optimized

- Mass Transfer

- Increased

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Volume Capacity

- 6.3L to 25m³

- Pressure Range

- Full vacuum to 6/10 bar

- Temperature Range

- -30°C to 260°C

- Baffle Style

- Integrated three baffles on vessel wall

- Material lining

- DD3009 glass

- Agitator type

- GlasLock® agitator

- Sensor Integration

- Integrated sensor on the shell

- Coil Zones

- Two coil zones

- Jacket Option

- Optional jacket

- Agitator type

- GlasLock® agitator

- Baffle design

- Integrated three baffles

- Coil zones

- Two coil zones

- Jacket option

- Optional jacket

- Pressure range

- Full vacuum to 6/10 bar

- Temperature range

- -30°C to 260°C

- Interchangeability

- Compatible with standard reactors of same size