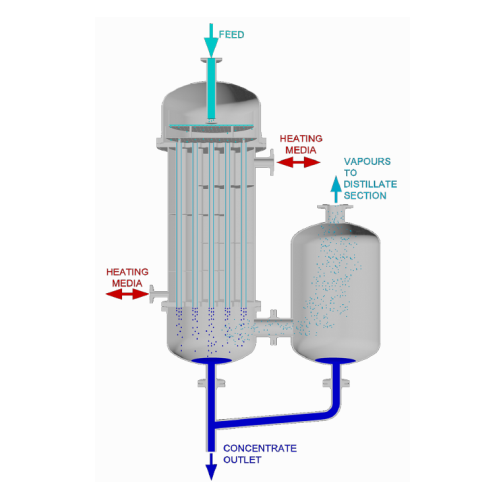

Falling film evaporator for thermal separation

Optimize energy efficiency in separation processes by utilizing gravity-driven liquid film technology, ideal for reducing exposure to thermal stress and preserving valuable components during evaporation and distillation.

Facilitates Efficient Liquid-Gas Separation and Distillation

The Falling Film Evaporator from De Dietrich Process Systems is engineered for efficient distillation and separation tasks in demanding industries like biopharmaceuticals and specialty chemicals. It utilizes gravity to distribute liquid evenly through its vertical tubes, reducing residence time and optimizing volatile fraction evaporation. This equipment excels in applications such as the production of insulin, antibiotics, and active pharmaceutical ingredients (APIs).

Designed for continuous operation, its multiple effect evaporation and mechanical vapor recompression significantly cut down energy costs. Constructed from corrosion-resistant materials, it ensures durability in harsh chemical environments. The evaporator integrates seamlessly into existing production lines with its PLC-controlled systems, enabling precise automation and monitoring. Meeting industry standards, it supports GMP and FDA compliance for pharmaceutical use.

The unit is customizable, offering engineering support for specific process requirements, ensuring it meets diverse operational needs while maintaining high efficiency and low operational costs. Its CIP (Clean-In-Place) feature ensures fast and safe cleaning, minimizing downtime and maintaining product integrity.

Benefits

- Optimizes energy use through multiple effect evaporation, reducing operational costs.

- Minimizes product degradation with low residence time, ensuring high-quality output.

- Supports compliance with GMP and FDA standards, ideal for pharmaceutical processes.

- Customizable design integrates seamlessly into existing systems, enhancing workflow efficiency.

- Facilitates easy cleaning with CIP capabilities, reducing downtime and contamination risk.

- Applications

- Green chemistry, Fine chemicals, Specialty chemicals, Biopharmaceuticals, Essential oils, Plant-based ingredients, Pharmaceuticals

- End products

- Paracetamol, Botanical extracts, Lavender oil, Insulin, Antibiotics, Plant extracts, Natural dyes, Fragrance oils, Herbal extracts, Flavoring agents, Specialty additives, Active pharmaceutical ingredients (apis)

- Steps before

- Preheating, Pre-filtration, Concentration

- Steps after

- Condensation, Crystallization, Separation

- Input ingredients

- product feed, liquid film

- Output ingredients

- volatile fraction

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Residence Time

- Low

- Energy Reduction

- Suitable for mechanical vapor recompression

- Evaporation Method

- Falling film

- Fluid Handling

- Minimum liquid film maintained by gravity

- Configuration

- Multiple effect

- Working Mechanism

- Falling Film

- Residence Time

- Low

- Batch vs. Continuous Operation

- Continuous

- Energy Efficiency

- Suitable for Multiple Effect Evaporation

- Cost Efficiency

- Minimal Investment

- Corrosive resistance (e.g. acids)

- High

- Cleanability

- Easy Clean

- Biological compatibility

- Not Applicable

- Abrasion resistance

- Moderate

- Density/particle size

- 0.5–2.5 g/cm³

- Foaming

- Minimal

- Separation Efficiency

- High

- Energy Efficiency

- Low Energy Cost

- Machine footprint

- Compact

- Tubes distribution

- Through top distribution system

- Feed method

- Top feed via distribution system

- Liquid film movement

- Downward by gravity

- Discharge method

- Top/bottom (depending on configuration)

- Distribution System

- Customized for uniformity

- Configuration

- Top or bottom evaporation

- Integration Possibilities

- Multiple effect or mechanical vapor recompression

- Control System

- PLC / Manual options

- Footprint

- Compact design options

- Energy Efficiency Integration

- Energy cost reduction features