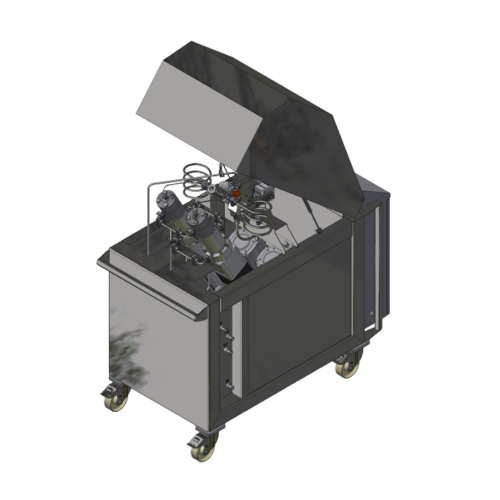

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formulations with this high pressure solution, optimizing homogenization and emulsification processes for enhanced product quality and consistency in demanding applications.

Processes High-Pressure Homogenization and Emulsification

The ATOMIX® High Pressure Homogenizer from Kinematica AG is engineered for pharmaceutical, nutraceutical, and cosmetic industries, providing superior homogenization and emulsification. Utilizing an optimized double-piston pump, it offers silent, vibration-free operation and efficient energy use with 30% reduction at high viscosities. Achieving up to 1.2 L/min throughput at a max pressure of 2500 bar, it expertly produces liposomes, emulsions, and sterile injectables. The CIP/SIP capabilities ensure compliance with GMP standards for seamless cleaning and sterilization. Its counter-jet working chamber design minimizes cavitation, extending component life and reducing investment costs, while controlled flow guidance enhances product quality. Customizable features and engineering support facilitate seamless integration into your production line.

Benefits

- Achieves precise particle size reduction for improved product performance and consistency.

- Minimizes production costs with energy-efficient, cavitation-limiting design.

- Ensures compliance with stringent industry standards via CIP/SIP for hygiene-critical applications.

- Operates quietly, enhancing workplace safety and comfort.

- Facilitates integration, with robust engineering support for seamless production line placement.

- Applications

- Food, Liquid formulations, Fine chemicals, Nutraceuticals, Cosmetics, Biopharmaceuticals, Essential oils, Life science, Pharmaceuticals

- End products

- Sterile injectable drugs, Anti-aging serums, Skincare creams, Paint suspensions, Detergent solutions, Inks, Fragrances, Plant extracts, Vitamin supplements, Flavor emulsions, Vaccine formulations, Emulsions, Herbal extracts, Nutritional drinks, Probiotic beverages, Liposomes, Protein suspensions

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Sterilization, Packing

- Input ingredients

- highly viscous material, nutraceuticals, cosmetic ingredients, pharma materials

- Output ingredients

- small droplets, narrow droplet size distribution, improved product quality

- Market info

- Automation

- Electromechanical

- Max. throughput

- 1.2 L/min

- Max. working pressure

- Max. 2500 bar

- Motor power

- 10 kW

- Piston type

- Double piston

- Pulsation-free conveyance

- Yes

- CIP/SIP

- Yes

- Energy efficiency

- 30% reduced energy at high viscosities

- Working chamber type

- Counter-jet with radial diffuser

- Droplet size distribution

- Small and narrow

- Working mechanism

- 2-piston pump, electric

- Integrated steps

- Pulsation-free conveyance

- CIP/SIP

- Yes, for Pharma applications

- Flow type

- Inline Continuous

- Energy efficiency

- 30% reduced energy at high viscosities

- Automation level

- Not specified

- Cleaning method

- CIP / SIP

- Pulsation-free system

- Phase-shift of pistons

- Noise level

- Quiet operation

- Environmental impact

- No motor cooling needed

- Cleanability

- CIP/SIP for Pharma applications

- Corrosive resistance (e.g. acids)

- High resistance

- Density/particle size

- Applicable to high viscosities

- CIP/SIP

- CIP / SIP

- Control panel type

- Electronic

- Customization of the electric pump

- Silent production