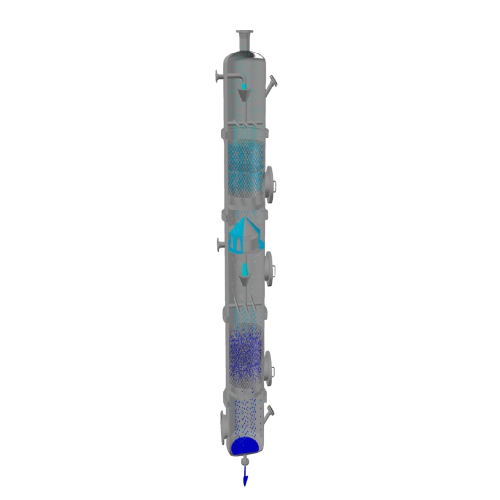

Rectification column for close boiling point separation

Achieve high-purity separation and distillation for compounds with close boiling points, ensuring your production line meets stringent quality standards for pharmaceuticals, specialty chemicals, and essential oils.

Separates and Purifies High-Purity Liquid Compounds

The Rectification Technology system by De Dietrich Process Systems is engineered to deliver precise separation and purification of liquid compounds with close boiling points. Utilizing advanced in-house process simulation software, this system optimally calculates theoretical stages, reflux flow, and pressure drop to ensure efficient operation. It is ideal for high-purity applications within the pharmaceuticals, fine chemicals, and biopharmaceutical industries. Capable of handling both continuous and batch operations, the system supports a range of outputs, from active pharmaceutical ingredients to essential oils. Its integration with existing production lines is seamless, facilitated by advanced PLC controls and options for remote monitoring. Designed for energy and solvent efficiency, this system also offers material options like stainless steel for robust chemical compatibility. Compliance with industry standards such as GMP and FDA is ensured, while engineered customization is available to meet your specific processing requirements.

Benefits

- Ensures high-purity output for critical chemical and pharmaceutical applications.

- Increases production efficiency with balanced reflux flow and pressure drop control.

- Adaptable to both continuous and batch processes for flexible manufacturing schedules.

- Lowers operational costs through energy-efficient design and optimized solvent usage.

- Provides robust integration with existing systems, minimizing setup time and complexity.

- Applications

- Specialty chemicals, Fine chemicals, Biopharmaceuticals, Essential oils, Plant-based ingredients, Pharmaceuticals

- End products

- Bioactive compounds, Biologic drugs, Active pharmaceutical ingredients (apis), Plant extracts, High-purity fine chemicals, Fragrance compounds, Peppermint essential oil, High-purity specialty chemicals, Lavender essential oil, Flavor compounds, Rose essential oil

- Steps before

- Mixing, Separation, Extraction, Process Simulation

- Steps after

- Purification, Condensation, Drying, Waste Gas Treatment

- Input ingredients

- mixtures, compounds close in boiling point

- Output ingredients

- high purity compounds

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Theoretical Stages

- Multiple stages

- Purity Level

- High purity

- Reflux Flow Rate

- Optimal controlled

- Pressure Drop

- Minimized

- Operation Mode

- Continuous/Batch

- Entry Points

- Top/Center/Bottom

- Working mechanism

- Distillation columns with multiple entry points

- CIP/SIP Integration

- CIP 121°C / SIP 135°C

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Changeover time

- N/A

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Top, Center, Bottom

- Control panel type

- PLC / HMI

- Integration possibilities

- Process simulation software

- Entry point options

- Top / Center / Bottom