Chromatography systems for large-scale biopharmaceutical purification

Ensure precision purification of biopharmaceuticals with advanced chromatography systems designed for seamless integration into your production line, from initial sampling to final processing stages.

Purifies and Separates Biopharmaceutical Compounds

The AutoPrep and AutoSep series from TRUKING Technology are chromatography systems designed for the precise purification and separation of biopharmaceutical compounds. These systems excel with a sophisticated algorithm that enables fully automatic sample loading, collection, and monitoring. Ideal for applications involving insulin, monoclonal antibodies, vaccines, and more, this equipment supports both pilot and large-scale production. The AutoPrep series can process multiple samples concurrently with its multi-inlet system, and its modular installation simplifies maintenance. Equipped with a remote monitoring capability, it ensures efficient process control. Constructed to meet GMP regulations, it facilitates seamless integration into existing production lines and offers energy efficiency through optimized flow path management. Whether for R&D or manufacturing, these systems provide critical support in achieving consistent, high-purity products.

Benefits

- Enhances production efficiency with fully automated sample processing, minimizing manual intervention.

- Ensures high-purity output, critical for sensitive biopharmaceutical applications like vaccine production.

- Offers seamless integration with existing systems, reducing installation time and costs.

- Supports compliance with GMP standards for safe pharmaceutical manufacturing.

- Minimizes operational costs through energy-efficient flow path optimization.

- Applications

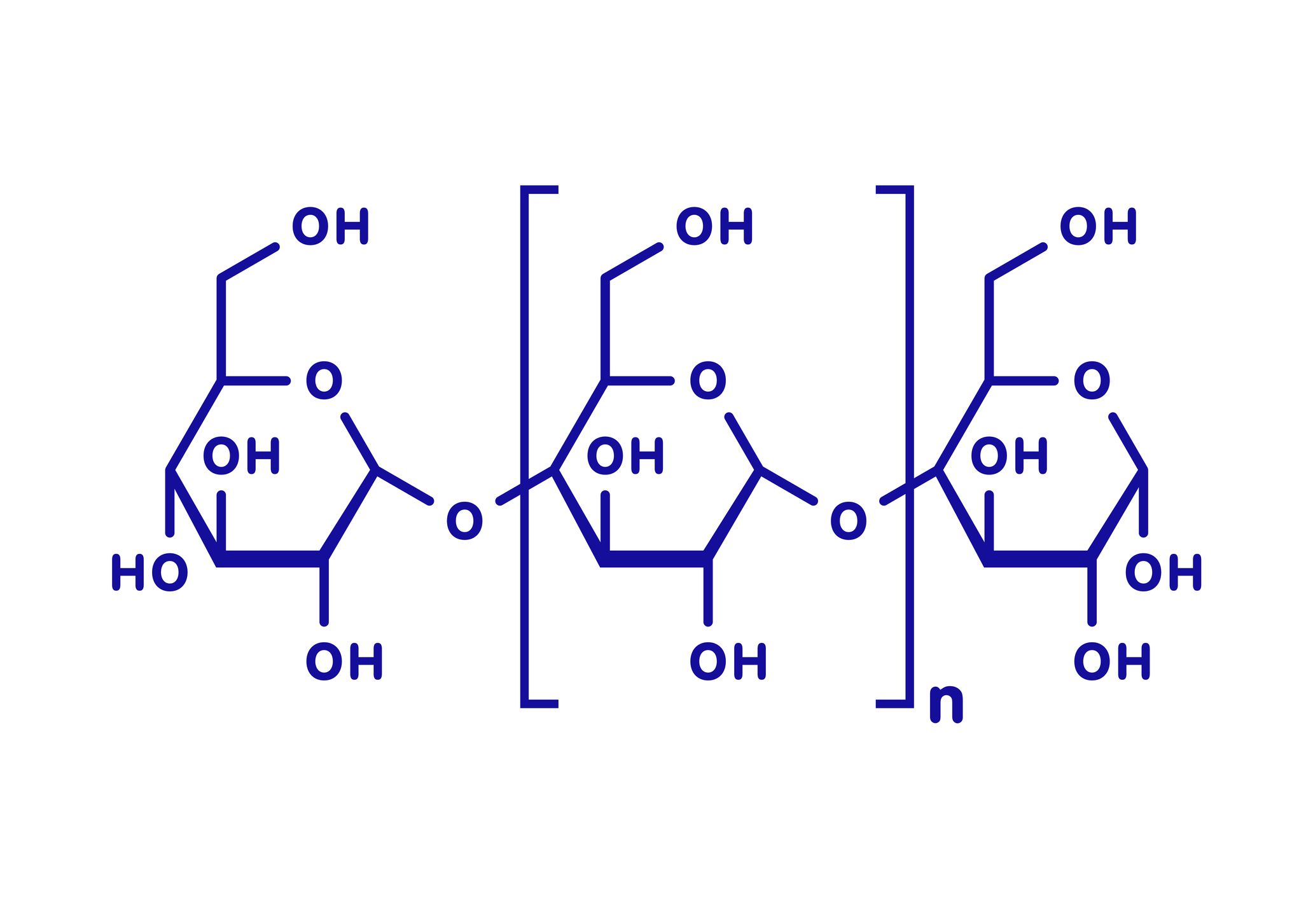

- Polysaccharides, Vaccines, Natural products, Monoclonal antibodies, Biopharmaceuticals, Blood products, Laboratory-level proteins, Recombinant proteins

- End products

- Erythropoietin, Heparin, Insulin, Lab-grade enzymes, Plant extracts, Rituximab, Immunoglobulins, Hepatitis b vaccine

- Steps before

- Purification, Separation, Preparation, Extraction, Concentration

- Steps after

- Sterilization, Packing, Inspection, Storage, Distribution

- Input ingredients

- monoclonal antibodies, insulin, blood products, vaccines, recombinant proteins, buffers, sample inlets, polysaccharides, natural products

- Output ingredients

- purified biopharmaceuticals, purified monoclonal antibodies, purified insulin, purified blood products, purified vaccines, purified recombinant proteins, purified laboratory-level proteins, collected samples

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Fully automatic

- Sampling Pump Configuration

- Two binary plunger pumps and one sampling pump

- Buffer and Sample Inlet Capacity

- 8 buffers and 8 sample inlets

- Bubble Sensors

- 2 sensors

- Column Flow Direction Switching

- Forward, reverse, bypass

- Outlet Capacity

- Up to 8 outlets

- Modular Installation

- All valves, pumps, and detectors

- Sample Loading

- Fully automatic

- Process Parameter Optimization

- Automatic optimization

- Remote Monitoring

- Real-time monitoring

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Low / Medium / High

- Container Size and Shape

- Vial / Ampoule / Bottle

- Machine footprint

- Compact/Standard

- Tank size

- Varies based on application

- Discharge method

- Automatic/Manual

- Control panel type

- Touch/Remote

- Control panel type

- HMI with touch screen