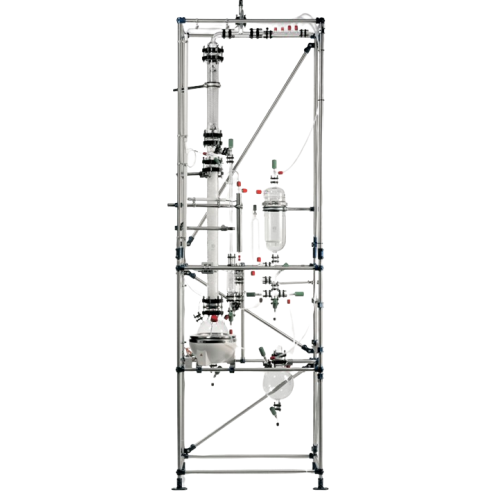

Solid/liquid extraction system for industrial applications

Optimize your solid-liquid extraction needs with a compact multifunctional system designed for diverse extraction modes, ensuring precision and adaptability in handling various compounds, from active pharmaceutical ingredients to specialty chemical formulations.

Extracts and Concentrates Bioactive Compounds Efficiently

The 1.5L Solid/Liquid Extractor from De Dietrich Process Systems is designed to efficiently extract and concentrate bioactive compounds, essential oils, and specialty chemicals. This versatile system features three extraction modes: trickle bed, underflow, and Soxhlet, catering to various applications, including pharmaceuticals, fine chemicals, and biopharmaceuticals. It integrates a 6L spherical evaporator with electrical heating, enabling precise solvent temperature control between cooling fluid levels and the solvent’s boiling point. Capable of operating within a wide temperature range (20 to 150°C), it ensures efficient extraction while maintaining material integrity with its borosilicate glass construction. Suitable for R&D and pilot operations, the system supports batch and bench-top processes, making it ideal for fine chemical producers and specialty chemical manufacturers. Additionally, its modular design includes compact valves and quick-release couplings, facilitating easy cleaning, maintenance, and extraction basket changes.

Benefits

- Enhances extraction efficiency with flexible operation modes tailored to diverse application needs.

- Minimizes solvent waste through precise evaporation and condensation processes.

- Maintains product integrity with corrosion-resistant borosilicate glass construction.

- Reduces process variability with customizable temperature settings for optimal solvent conditions.

- Simplifies maintenance and cleaning with a modular design that allows easy access and disassembly.

- Applications

- Green chemistry, Fine chemicals, Specialty chemicals, Biopharmaceuticals, Essential oils, Plant-based ingredients, Precious metals, Vegetal solid - liquid extraction, Pharmaceuticals

- End products

- Alkaloids, Cosmetic raw materials, Active pharmaceutical ingredients, Botanical extracts, Fragrances, Nutraceuticals, Bioactive compounds, Plant extracts, Flavonoids, Organic acids, Bioprocessed proteins, Herbal tinctures, Dietary supplements, Antioxidants, Specialty chemical formulations

- Steps before

- Solvent preparation, Purification, Solvent preconcentration

- Steps after

- Discharging, Cleaning, Cooling

- Input ingredients

- solids, solvent, cooling fluid

- Output ingredients

- extract, solvent vapors, preconcentrated extract

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Extraction Capacity

- 1.5l

- Solvent Evaporator Capacity

- 6l

- Extraction Receiver Volume

- 4l

- Heater Power

- 300W

- Evaporator Power

- 1700W

- Condenser Surface Area

- 0.3m²

- Cooler Surface Area

- 0.03m²

- Extraction Temperature Range

- 20°C to 150°C

- Extraction Pressure Range

- -1 to atmospheric pressure

- Solvent Temperature Range

- Cooling fluid temperature to boiling point

- Dimensions

- 1000 x 600 x 3300mm

- Column Diameter

- DN80

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Extraction modes

- Trickle bed / Soxhlet / Underflow

- Temperature control

- 20 up to 150°C

- Corrosive resistance (e.g. acids)

- Borosilicate glass 3.3, PTFE, PFA

- Thermal resistance

- 20°C up to 150°C

- Cleanability

- Compatible with various cleaning methods

- Density/particle size

- Suitable for a variety of densities and particle sizes

- Machine footprint

- 1000 x 600 x 3300 mm

- Basket size

- 1.5 L

- Extraction receiver volume

- 4 L

- Evaporator volume

- 6 L

- Column size

- DN80 with Raschig-rings

- Discharge method

- Manual extraction and discharge

- Control panel type

- PLC-controlled

- Extraction modes

- Trickle bed, Underflow, Soxhlet

- Solvent preparation

- 6l spherical evaporator

- Solvent temperature adjustment

- Cooling fluid to boiling point