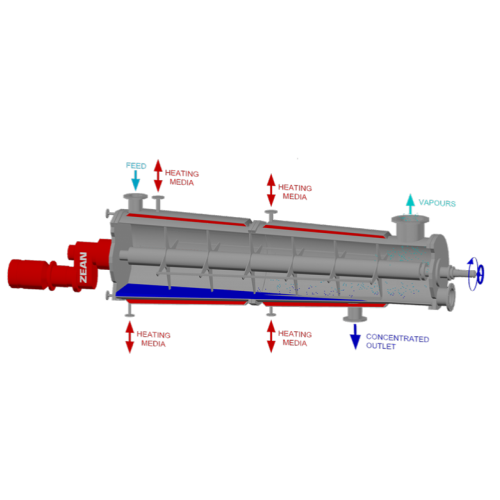

Horizontal thin film evaporator for continuous distillation

Experience precise control over evaporation and distillation processes with our horizontal thin film evaporator, ideal for achieving high-purity outputs in continuous operations.

Facilitates Continuous Evaporation and Distillation

The Horizontal Thin Film Evaporator from De Dietrich Process Systems specializes in continuous evaporation and reactive distillation, catering to industries like pharmaceuticals, fine chemicals, and green chemistry. Utilizing a horizontal arrangement, it ensures rapid evaporation by efficiently controlling product residency time. Ideal for producing antibiotics, APIs, and natural extracts, this equipment transforms challenging feedstock into high-purity outputs. It integrates seamlessly into production lines with its PLC-controlled system, enabling remote operation and monitoring. Its energy-efficient design reduces consumption by utilizing optimized motor controls, and it is constructed from corrosion-resistant materials suitable for handling aggressive chemicals, ensuring longevity and reliability. Fully compliant with industry standards, it offers customization options and engineering support to meet unique processing needs. Equipped with a CIP system, it ensures effortless cleaning and minimized downtime, making it a critical component for high-speed, continuous operations.

Benefits

- Maximizes continuous production efficiency with controlled product residency.

- Enhances separation purity and yield for complex chemical processes.

- Reduces energy costs through optimized motor control and evaporating efficiency.

- Complies with stringent industry regulations, ensuring high-quality outputs.

- Facilitates easy integration and minimal maintenance with corrosion-resistant materials and CIP system.

- Applications

- Green chemistry, Specialty chemicals, Fine chemicals, Biopharmaceuticals, Plant-based ingredients, Pharmaceuticals

- End products

- Botanical concentrates, Active pharmaceutical ingredients (apis), Antibiotics, Plant extracts, High-purity chemicals, Natural extracts, Flavors and fragrances, Solvent recovery, Specialty chemical compounds, Essential oils

- Steps before

- Reaction, Mixing, Liquid/Liquid Extraction, Solid/Liquid Extraction, Hydrogenation

- Steps after

- Reactive Distillation, Vacuum Drying, Filtration/Drying, Neutralisation and Valorisation, Acid Treatment

- Input ingredients

- chemical solutions, organic compounds, reactive chemicals, viscous liquids

- Output ingredients

- evaporated compounds, distillate, volatile components, purified solutions

- Market info

- De Dietrich is renowned for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in chemical process systems, glass-lined reactors, and filtration technologies, with a strong reputation for innovation, reliability, and safety in the chemical and pharmaceutical industries.

- Arrangement

- Horizontal

- Evaporation Rate

- High

- Operation Type

- Continuous

- Reaction Capability

- Reactive distillation

- Product Residency Time Control

- Yes

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- High evaporation rates

- Cleaning method

- CIP / Manual

- Reactive Distillation

- Yes

- Machine footprint

- Horizontal configuration

- Shape and size

- Thin film evaporator design

- Feed method

- Continuous feed

- Discharge method

- Continuous discharge

- Residency time control

- Adjustable

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / DCS

- Material construction

- Stainless steel / Glass-lined

- Heating option

- Steam / Electric / Thermal oil

- Modular design

- Expandable capacity