Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, utilizing pick and place robots to enhance speed and accuracy.

Automates Flow Wrapping and Precise Product Placement

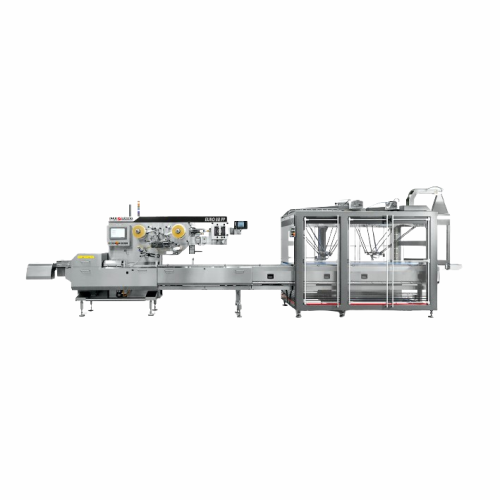

The EURO 88 PP from IMA Group features a sophisticated flow wrapping line with Pick & Place robots, designed to optimize confectionery and bakery packaging operations. Its innovative design incorporates 4-axis robots and a vision system, enabling precise, high-speed product picking and placement directly onto the flow wrapper chain. This equipment excels in handling diverse end-products like chocolate bars, pastries, and bread rolls, effortlessly integrating into high-speed, continuous production lines. Engineered for performance, it adjusts to varying production capacities with customizable robot configurations, ensuring seamless automation. With dimensions accommodating products of various sizes, the EURO 88 PP ensures consistent wrapping quality, enhancing productivity in confectionery and bakery sectors.

Benefits

- Enhances packaging speed and accuracy with automated product placement.

- Increases production efficiency by minimizing manual handling and errors.

- Adaptable to various product sizes, improving flexibility in production lines.

- Reduces labor costs through seamless integration and automation.

- Supports high-speed operations, maximizing production throughput without compromising quality.

- Applications

- Bakery products, Confectionery

- End products

- Packaged cakes, Bread rolls, Soft caramels, Marshmallows, Muffins, Candy sticks, Chocolate bars, Croissants, Pastries, Biscotti

- Steps before

- Product Receiving, Sorting, Alignment

- Steps after

- Packing, Cartoning, Case Packing, Palletizing

- Input ingredients

- confectionery products, bakery products

- Output ingredients

- flow wrapped products, packaged confectionery, packaged bakery items

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Automation

- Fully automated with 4 axis Pick, Place robots

- Speed

- High-speed precision

- Capacity

- Customized according to production needs

- Product Size Range (Length)

- 30–160 mm

- Product Size Range (Width)

- 15–100 mm

- Product Size Range (Thickness)

- 5–60 mm

- Precise Picking

- Vision system to scan products' positions

- Position Accommodations

- Can pick products positioned up to +/-45°

- Film Reel Inner Diameter

- 70–79 mm

- Film Reel External Diameter

- -

- Film Reel Width

- 350/500 (opt) /650 (box motion) mm

- Film Reel Max Weight

- 25 kg

- Payload Capacity

- High

- Working Mechanism

- Flow wrapping with Pick, Place

- Integrated Steps

- Pick, Place robots receiving products from upstream line

- Automation Level

- Fully automated with 4 axis robots

- High-Speed Precision

- Yes

- Vision System

- Product position scanning

- Operating Angles

- Products positioned up to +/-45°

- Production Capacity

- Customized according to need

- Discharge method

- Flow wrapper chain

- Pick,Place Robot Configuration

- Customizable number of 4 axis robots

- Control System

- Vision system for product scanning

- Integration Capability

- Integration with upstream line

- Film Reel Dimensions

- Custom reel width options (350/500/650 mm)

- Product Size Compatibility

- Customizable for product sizes from 30mm to 600mm