ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing requires special equipment for safety and efficiency. Often used as part of a sugar-milling line and flour handling line in the confectionery industry, indoor silos need to offer ATEX-rated protection against the risk of powder explosion, while at the same time offering maximum flexibility by using automated control systems for charging and discharging.

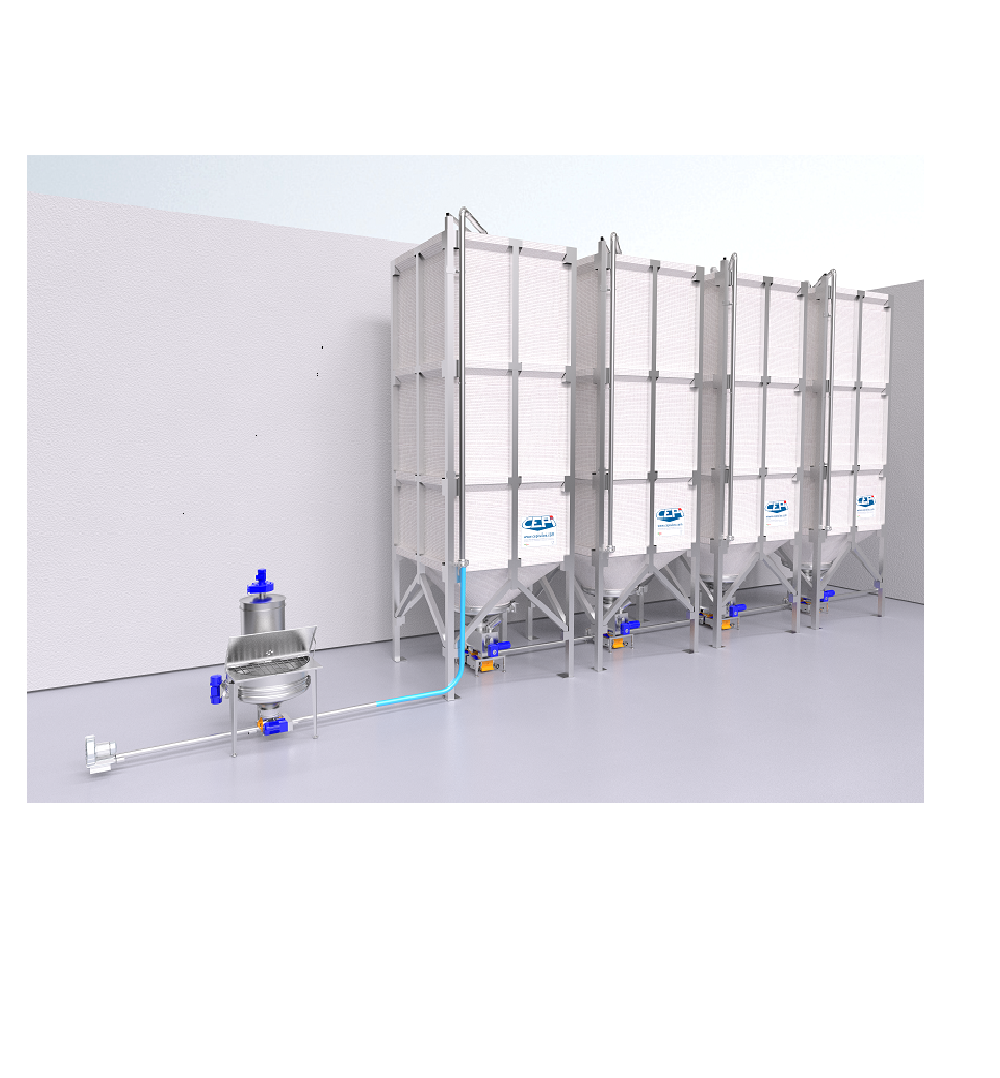

Modular indoor storage silos using anti-static glass fiber fabric and flexible extraction systems

The SilSystem silo solution from Cepi has been engineered to be the perfect fit for hygienic macro storage of all main powder raw ingredients used in the food industry. They are particularly suitable for abrasive products like sugar and are the perfect solution for confectionery manufacture.

Constructed using a patented antistatic HT fabric – a unique glass fibre product – silos are also built with Cepi’s patented equipotential earthing system. This combination makes them extremely safe for use with explosive powders.

The safety-first design principle also extends to the use of ATEX-approved butterfly or rotary valves or feed screws for dosing. These silos also feature a full overpressure and under-pressure prevention system.

Able to be paired with bag dischargers of variable capacity, the SilSystem silos feature real-time weight control and fully integrated automation with filtering roofs. Silos can be fitted with either vibrating cone or fluid-bed extraction systems, offering complete flexibility to match your product needs.

Benefits

- Designed to withstand abrasive products like sugar

- Highest levels of safety thanks to patented anti-static technology

- Easily integrate with automation

- Choice of extraction options to meet your needs

- Compatible with all Cepi conveying and dosing systems