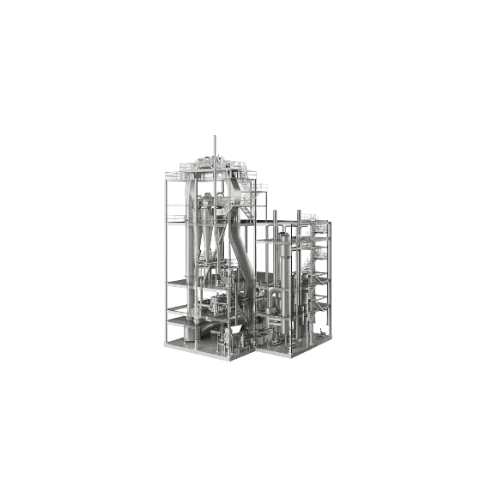

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed for efficient moisture control in challenging feed materials like pastes and slurries, ensuring consistent product quality across various applications.

Processes and Dries Diverse Industrial Materials

The Feed-Type Ring Dryer by GEA is designed for industries requiring efficient drying of complex materials, such as agrifood, chemical, and mineral sectors. This dryer stands out for its use of a single-blade manifold for selective residence time, enhancing drying efficiency and particle size control. The system uses a disintegrator to recycle semi-dried materials, improving thermal efficiency and product quality. Ideal for drying wheat gluten, powdered milk, and ceramic slurries, it handles various materials including powders, cakes, and slurries. Capable of operating continuously at high speeds, it’s customizable for integration into existing lines, offering energy savings and solvent recovery. Constructed with options for stainless steel, it supports sustainable operations with reduced exhaust temperatures and emission improvements.

Benefits

- Enhances product quality with precise moisture control and particle size management.

- Reduces energy consumption through optimized recycling of heat and materials.

- Increases operational efficiency with continuous high-speed processing.

- Supports diverse material feeds, minimizing production line disruptions.

- Adapts to custom configurations for seamless integration into existing systems.

- Applications

- Mineral, Gels, Slurries, Granules, Solvent recovery, Chemical, Agrifood, Pastes, Cakes, Powders, Flakes

- End products

- Powdered milk, Pigment pastes, Starch powder, Mineral powders, Ceramic slurries, Soy fiber, Solvent extracts, Wheat gluten, Instant coffee granules, Gel concentrates, Pharmaceutical granules

- Steps before

- Emulsification, Grinding, Mixing

- Steps after

- Cooling, Packaging, Cyclone Collection

- Input ingredients

- powders, cakes, granules, flakes, pastes, gels, slurries, sticky materials, wet feed, fibrous feed products

- Output ingredients

- dry product, dry light product, conditioned material

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Evaporative Capacity

- Large

- Automation

- Custom designed systems

- Operation Environment

- Inert atmosphere

- Residence Time

- Selective, adjustable

- Feed Material Types

- Powders, cakes, granules, flakes, pastes, gels, slurries

- Thermal Efficiency

- Increased through design

- Disintegrator Type

- Cold disintegrator

- Exhaust Temperature

- Reduced

- Cyclone Collection Efficiency

- Improved

- Gas Recycle Option

- Partial gas recycle

- Working Mechanism

- Centrifugal forces, manifold with internal classifier

- Integrated Steps

- Pre-separator, manifold, disintegrator

- Batch vs. Continuous Operation

- Continuous

- Control of Particle Size

- Adjustable splitter blade

- Moisture Control

- Through manifold and disintegrator

- Exhaust Temperature Control

- Enhanced by recycling system

- Suitability for Difficult Materials

- Yes, selectively extended residence time

- Flexible Design

- Custom designed systems based on applications

- Energy Efficiency

- Enabled by selective recycling

- Footprint

- Reduced compared to traditional designs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Complex material drying

- Yes

- Footprint

- Reduced footprint

- Manifold design

- Single-blade

- Discharge method

- Selective residence time for light/dry product

- Evaporative capacity

- Large evaporative capacities

- Configuration

- Open circuit and partial gas recycle

- Atmospheric operation

- Operation in an inert atmosphere

- Compact footprint

- Reduced footprint