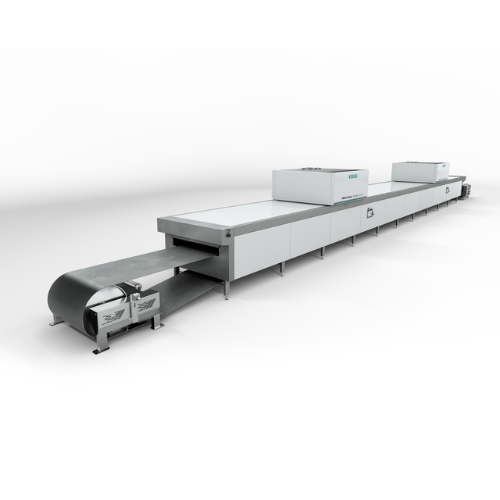

Industrial tunnel oven for biscuits and cakes

Achieve uniform baking results with optimized heat transfer and precise moisture control, perfect for high-speed industrial environments where consistent quality and efficiency are crucial.

Bakes Uniformly with Optimal Heat Transfer

The Meincke Turbu 4.0 from Bühler Group is a versatile indirect-fired convection tunnel oven designed for the industrial baking sector. What sets this oven apart is its precise heat management system, leveraging a double damper mechanism that optimizes burner heat for energy efficiency and consistent baking results. It excels in baking a wide range of products, including digestive biscuits, chocolate chip cookies, sponge cakes, margherita pizzas, and meat pies.

Operating continuously at high speeds, the Meincke Turbu 4.0 uses a unique system where air is preheated in a heat exchanger away from the baking chamber, ensuring no combustion gases contact your products. This results in a uniform, top-quality bake ideal for food manufacturers focused on high throughput and reliability. Modular in design, this oven allows for seamless integration into existing lines and can be customized with different configurations to meet your specific production requirements.

Engineered for durability and ease of maintenance, the oven also features an advanced ventilation system that effectively manages exhaust and air distribution. This comprehensive engineering not only supports energy-efficient operations but also reduces downtime, allowing for maximum productivity in the production of your baked goods.

Benefits

- Ensures uniform baking results with optimized heat transfer and precise temperature control.

- Saves energy and reduces operational costs through an efficient double damper system.

- Easily integrates into existing production lines with modular design, allowing customization for specific needs.

- Enhances product quality by preventing combustion gases from contacting baked goods.

- Minimizes downtime with robust, reliable engineering and simplified maintenance procedures.

- Applications

- Pizzas, Cookies, Biscuits, Pies, Cakes

- End products

- Digestive biscuits, Chocolate chip cookies, Margherita pizza, Meat pies, Sponge cakes

- Steps before

- Dough preparation, Extrusion, Shaping

- Steps after

- Cooling, Packing, Decorating, Sifting, Grading

- Input ingredients

- biscuits, cookies, cakes, pizzas, pies, raw materials

- Output ingredients

- baked goods, uniform baking results, end product

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Heating principle

- Indirect-fired convection

- Modular design

- 2 m long prefabricated module

- Energy efficiency

- Optimized heat transfer

- Heat control

- Double damper system

- Temperature distribution

- Top and bottom plenum distribution

- Ventilation system

- Adjustable damper system with fans

- Control system

- PLC-controlled

- Baking chamber characteristics

- Heated with indirect heat transfer

- Baking type

- Indirect-fired convection

- Oven adaptability

- Modular design

- Heat transfer optimization

- Double damper system

- Energy efficiency

- Fast response time

- Process chain

- Uniform baking results

- Heat distribution

- Adjustable damper system with fans

- Human safety feature

- No combustion gases contact with product

- Recipe consistency

- High repeatability of set-ups

- Heating principle

- Fan to burner chamber system

- Ventilation system

- Exhaust air mixed with fresh air

- Symbiotic heat use

- Conductive and thermal radiation

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade materials

- Cleanability

- CIP / Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Variety of product densities

- Machine footprint

- Modular design with 2 m prefabricated modules

- Oven shape and size

- Tunnel oven with configurable length

- Control panel type

- HMI/Touchscreen

- Modular design

- 2 m prefabricated module

- Heating method customization

- Conductive/Thermal radiation/Convection

- Ventilation system

- Adjustable damper system

- Heat exchange customization

- Top and bottom ducts control