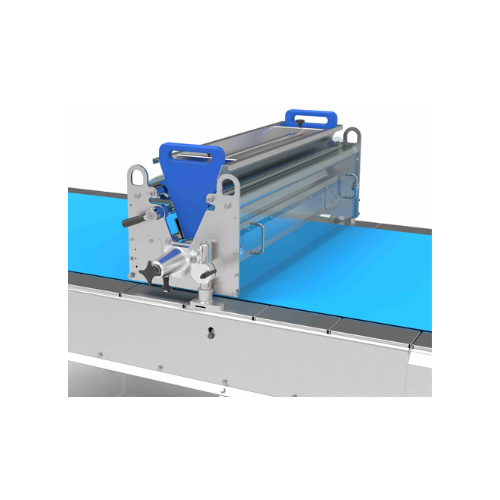

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and high-speed sprinkling, ensuring each product meets quality and appearance standards efficiently.

Sprinkles and Decorates Baked Goods and Snacks

The Meincke 1688 Sprinkling Unit from Bühler is designed to enhance your production line by providing precise and versatile decorative topping applications. This unit is ideal for bakery and confectionery producers seeking to add granulated sugar, nuts, seeds, and spices to their products. Utilizing easily replaceable sprinkling rollers, it supports quick product changes while ensuring even distribution through controlled roller speed and slit adjustments. Capable of adapting to the entire width or specific areas of your dough band, it supports both continuous and high-speed operations. The advanced design allows for efficient cleaning and maintenance, with removable parts to reduce downtime. This unit is well-suited for use in food, snacking, and bakery industries, integrating seamlessly with existing processes to maintain hygiene standards and improve production efficiency.

Benefits

- Enhances product appeal with precise and consistent topping applications.

- Minimizes downtime with quick roller change capability for fast product transitions.

- Increases operational efficiency through high-speed, continuous processing adaptation.

- Reduces cleaning time due to tool-free part removal, ensuring hygienic standards.

- Customizable application width enhances production flexibility across various product lines.

- Applications

- Baked goods, Biscuits, Snacks, Confectionery, Crispbreads, Nuts, Crackers, Swiss rolls, Spices, Sponge cakes

- End products

- Whole nut decorations, Superfine sugar coatings, Poppy seed toppings, Sesame seed garnish, Granulated sugar toppings, Salt sprinkles, Chopped nut toppings, Spiced coatings, Flaked almond decorations

- Steps before

- Dough preparation, Extrusion, Shaping

- Steps after

- Cooling, Packing, Decorating

- Input ingredients

- granulated sugar, superfine sugar, whole nuts, chopped nuts, flaked almonds, sesame seeds, poppy seeds, salt, spices

- Output ingredients

- biscuits, crackers, Swiss rolls, sponge cakes, crispbreads, snacks

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Sprinkling roller change

- Quick, tool-free

- Sprinkling accuracy

- Particle control via roller speed and slit size

- Particle type

- Granulated sugar, nuts, seeds, spices

- Cleaning method

- Easy, tool-free removable parts

- Sprinkling flexibility

- Full or partial dough band

- Hygiene standards

- Meets latest standards

- Working mechanism

- Sprinkler roller system

- Integrated steps

- Sprinkling, excess particle recovery

- Cleaning method

- Easy cleaning with removable parts

- Automation level

- Manual / Semi-automatic

- Changeover time

- Quick roller change

- Adaptability

- Full width or selected areas sprinkle

- Particle control

- Control via roller speed and slit size

- Cleanability

- Easy cleaning and maintenance

- Machine footprint

- Compact

- Discharge method

- Sprinkling roller with controlled slit

- Control panel type

- PLC-Controlled

- Compact footprint

- Yes

- Feed type

- Granulated sugar, nuts, seeds, salt, spices

- Sprinkling Width

- Full width or selected areas

- Roller Replacement

- Quick change

- Cleaning Method

- Tool-free removal

- Sprinkling Amount Control

- Roller speed and slit size