Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling systems, designed to optimize product quality and efficiency by ensuring precise temperature and moisture control during the crucial post-baking phase.

Cools, Stores, and Conveys Baked Goods Efficiently

The TOR Storage and Cooling Tower from GEA is designed for bakery producers seeking enhanced efficiency in space-constrained environments. This cooling tower integrates seamlessly into your production line, replacing traditional horizontal conveyors with a vertical tiered system for cooling and storing baked goods such as cookies, cakes, and breads. The system automates loading and unloading of trays, reducing manual handling and increasing throughput. Capable of natural and controlled cooling processes, the TOR ensures optimal moisture control and product quality. Its modular design allows customization to fit your plant’s specific capacity requirements, enhancing both integration and performance. With the ability to operate continuously and at high speeds, the TOR tower is an integral component for food manufacturers looking to streamline their processes.

Benefits

- Maximizes space efficiency with vertical cooling and storage design.

- Enhances product quality by ensuring controlled cooling and moisture levels.

- Reduces manual labor with automated tray loading and unloading.

- Customizable capacity to match specific production needs.

- Seamlessly integrates into existing high-speed bakery production lines.

- Applications

- Cookies, Biscuits, Breads, Pies, Crackers, Cakes, Pastries, Bakery products

- End products

- Gingerbread biscuits, Rye crackers, Butter cookies, Chocolate chip cookies, Sourdough breads, Pound cakes, Multigrain breads, Apple pies, Cherry pies, Croissants, Cheese crackers, Sponge cakes, Danish pastries

- Steps before

- Baking

- Steps after

- Product filling, Depanning, Packaging

- Input ingredients

- baked products, cookies, cakes, pies, breads, pastries, biscuits, crackers, dough cookies

- Output ingredients

- cooled products, ambient temperature products, set sugary cookie structures, cooled enough for safe handling, ready for injection or depanning, packed products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Cooling method

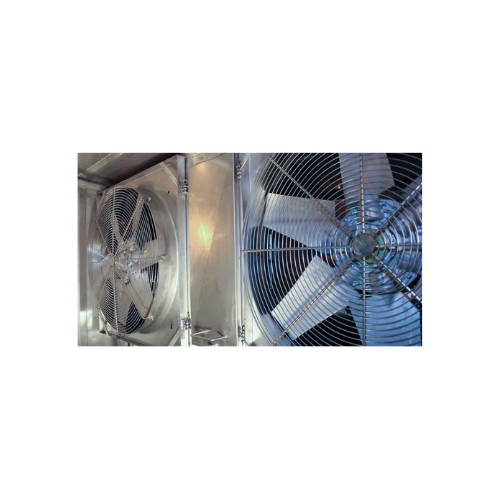

- Natural / Filtered air

- Cooling tower type

- Vertical TOR

- Automation Level

- Automated loading and unloading

- System integration

- Spiral freezers and coolers (S-Tec and A-Tec)

- Cooling stages

- Two-stage cooling and freezing

- Cooling conveyor type

- Long horizontal with curves / raised

- Conveyor compatibility

- Building layout specific

- Space saving

- Vertical system of tiers

- Working mechanism

- Vertical tier system

- Integrated steps

- Cooling, storage, unloading

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Automation level

- Automated loading and unloading

- Batch vs. continuous operation

- Inline continuous

- Abrasion resistance

- High

- Biological compatibility

- Food-grade, non-reactive

- Cleanability

- Easy to clean, CIP compatible

- Corrosive resistance (e.g. acids)

- Stainless steel, corrosion-resistant

- Density/particle size

- Suitable for varying densities

- Machine footprint

- Compact vertical design

- Tower system type

- Vertical ascending and descending tiers

- Tray storage capacity

- Customizable

- Discharge method

- Automatic loading/unloading

- Cooling conveyor length

- Modular to fit building layout

- System integration

- Seamlessly integrates into processing line

- Tray handling

- Automated tray movement

- System layout

- Curve and raised conveyor options

- Cooling conveyor design

- Customizable for ambient cooling

- Belt Width

- Various

- Integration Possibilities

- Seamless integration into processing line

- Automated Tray Storage

- Yes

- Tray Capacity Customization

- Customizable

- Cooling and Freezing Stages

- Two-stage

- Frost Management System

- Innovative

- Temperature and Moisture Control

- Controlled