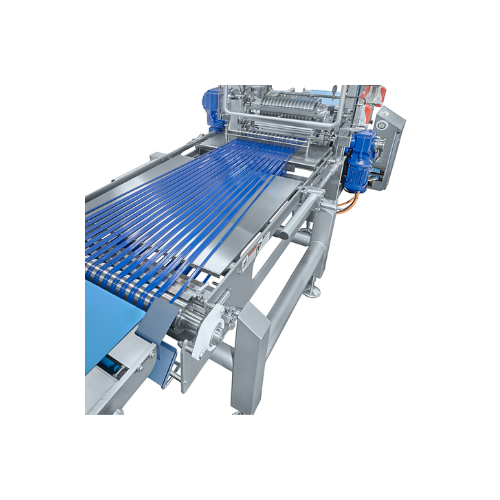

Industrial fanning belt for strand separation

Enhance your production line efficiency with precise strand separation, ensuring uniform fanning and optimal spacing for seamless integration into enrobing and packaging processes.

Separates and Fans Strands for Enrobing

The Fanning Belt CLBG from Bühler Group is essential for food manufacturers and confectionery producers, optimizing your production line by effectively separating and fanning strands for enrobing and packaging. Utilizing a flexible design, the CLBG adjusts product width quickly through its innovative belt strap arrangement, making it ideal for handling diverse products such as protein and granola bars, chocolate truffles, and artisan bread loaves. Built with a hygienic stainless steel framework, it ensures high cleanliness standards and easy maintenance, crucial for demanding food safety requirements. Operating in continuous, high-speed environments, the Fanning Belt CLBG seamlessly integrates into processing and packaging departments. Offering both lateral and up-and-down fanning options, it accurately positions strands for downstream processes, enhancing overall line efficiency.

Benefits

- Enhances product quality with precise strand separation and optimal fanning angles.

- Adapts to various product widths quickly, accommodating diverse manufacturing needs.

- Ensures high hygiene standards and simplifies maintenance with an open stainless steel design.

- Increases production efficiency by seamlessly integrating with enrobing and packaging processes.

- Reduces cleaning time with easy access for fast product changeovers.

- Applications

- Wafers, Fruit bar, Bakery solutions, Compounds, Cereal bars, Bars, Candy bars, Biscuits and cakes, Chocolate mass

- End products

- Artisan bread loaves, Chocolate truffles, Muesli bars, Nougat bars, Granola bars, Apricot fruit bars, Caramel centers, Cream-filled wafers, Shortbread cookies, Sponge cakes, Protein bars

- Steps before

- Strand slitting

- Steps after

- Enrobing, Packaging

- Input ingredients

- endless strand, food products

- Output ingredients

- fanned strands, prepared food items, enrobed products, packaged products

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Product Flexibility

- Adjustable belt strap arrangement

- Process Stability

- Accurate fanning with exact distances and angles

- Material

- Stainless steel

- Cleaning Method

- Easy access for cleaning

- Automation Level

- Manual/Adjustable

- Hygienic Design

- Open and easy access design

- Strand Fanning Method

- Lateral and up-and-down

- Fanning Angle

- Optimal for process stability

- Product Width Change

- Flexible at the outlet side

- Fanning method

- Lateral / Up-and-down

- Product width adjustment

- Flexible belt strap arrangement

- Cleaning access

- Easy / Open design

- Hygienic design

- Stainless steel construction

- Process stability

- Accurate strand separation

- Automation level

- Manual/Automatic

- Hygienic compatibility

- Stainless steel

- Cleanability

- High, with easy access

- Corrosive resistance

- Stainless steel

- Viscosity

- Thin / Medium / Thick

- 3A Sanitary Standards

- Compliant

- FDA compliance

- Compliant

- EHEDG certification

- Compliant

- CE marking

- Compliant

- Material

- Stainless steel

- Design Type

- Open design

- Discharge method

- Adjustable belt straps

- Control Panel Type

- Manual/Automated

- Product Width Adjustment

- Changeable arrangement of belt straps

- Strand Fanning

- Up-and-down for sticky products

- Hygienic Design

- Open design in stainless steel