Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensitive products while maintaining high-speed operation in continuous production lines.

Packages and Cartons Various Solid Products

The Topload Cartoner CLM from Viking Masek is a versatile carton packing machine designed to handle a wide variety of solid products. It operates in both straight-line and right-angle configurations, offering flexibility in high-speed, continuous production lines. With a capacity to neatly package products such as cereal, coffee, and medical supplies, it employs a servo-driven mechanism ensuring precise flap closing and gentle handling.

Applications span across food, beverage, and medical industries, efficiently packaging items from granola bars to syringes. The machine supports various flap closing methods—lock style, hot melt, or hot air systems—catering to different product requirements. It achieves speeds of up to 200 cartons per minute, with easy format changeovers and excellent accessibility for smooth integration into existing lines. Engineered from rugged stainless steel with IP54 construction, it offers durability and resilience.

The CLM is equipped with Siemens or Allen Bradley controls, allowing for precise speed and glue adjustments via the HMI. Additionally, it offers off-the-shelf components for easy maintenance and replacement. Options for remote diagnostics and customized electronics ensure adaptability to specific operational needs, while its IP65 washdown construction option caters to rigorous hygiene standards.

Benefits

- Enhances operational efficiency with high-speed, continuous packaging capabilities.

- Minimizes damage and waste with gentle handling and precise flap closing.

- Reduces labor costs and setup time with easy format changeovers.

- Ensures reliability and longevity with durable stainless steel construction.

- Facilitates seamless production line integration with versatile configuration options.

- Applications

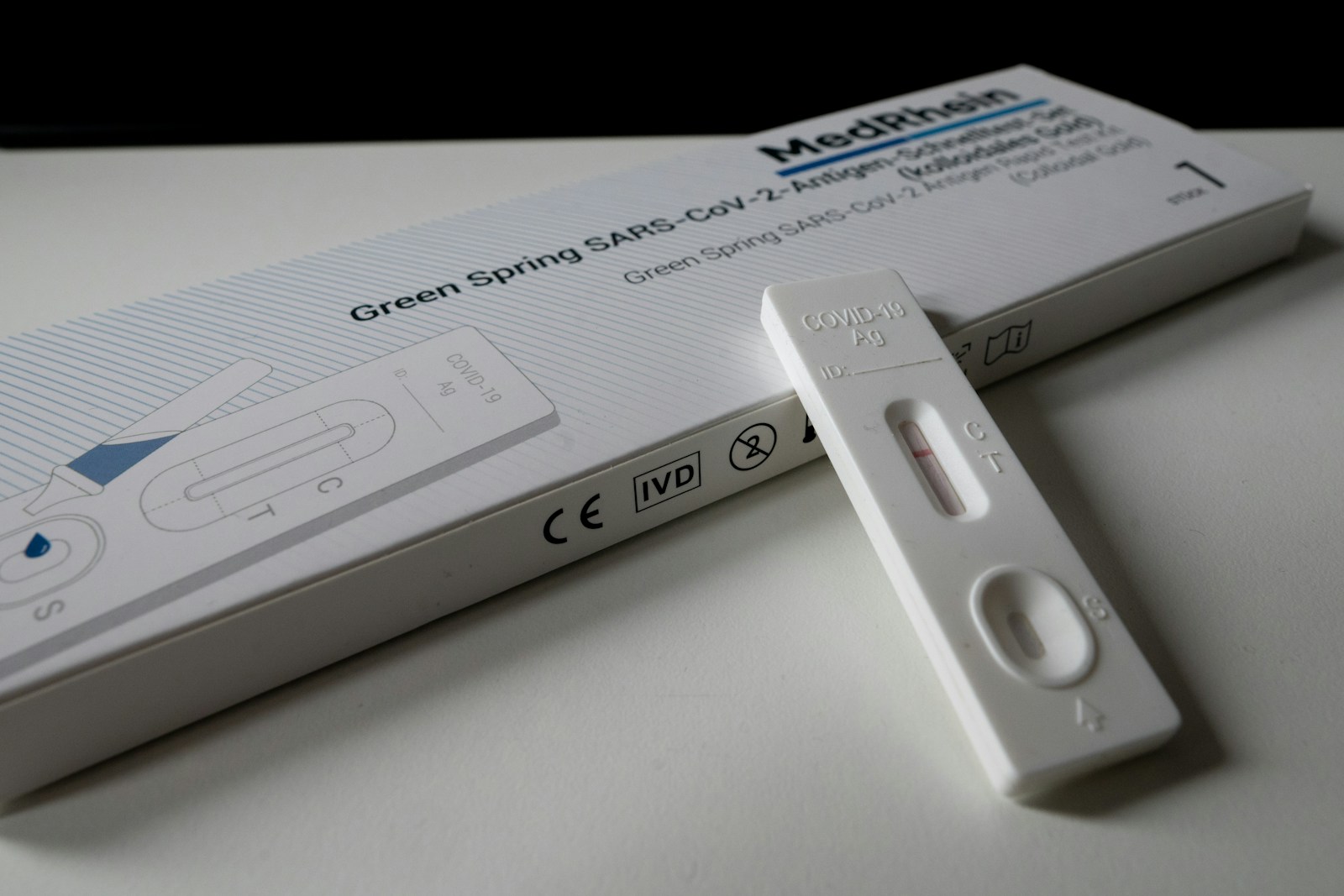

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Powders

- End products

- Dog biscuits, Spaghetti, Bottled water, Potato chips, Protein powder, Hemp oil capsules, Jasmine rice, Cleaning sponges, Salmon fillets, Granola bars, Chicken breasts, Face masks, Orange juice, Frozen peas, Croissants, Cheddar cheese, Breakfast cereal, Fresh apples, Cornflakes, Syringes, Blood test kits, Cat kibble, Black beans, Ground coffee, Almonds, Dietary supplements, Organic granola, Carrot sticks, Chocolate bars, Paracetamol tablets

- Steps before

- Filling cartons, Product loading

- Steps after

- Sealing cartons, Carton labeling, Palletizing

- Input ingredients

- cartons, unsealed cartons, various product types

- Output ingredients

- sealed cartons, closed flap cartons, packaged products

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 200 cpm

- Carton Size (Intermittent) - Min

- 50 mm x 80 mm x 25 mm

- Carton Size (Intermittent) - Max

- 225 x 300 x 200 mm

- Air Pressure

- 6 bar (15–18 CFM at 90 PSI)

- Power Supply

- 6 - 12kVA

- Machine Footprint

- 1100 mm W x 2800 - 3500 mm L x 2000 mm H

- Weight

- 900 - 1300 kg

- Flap Closing Configuration

- One, two, or three flap closing

- Lock style

- Hot melt or hot air systems

- Construction Material

- Rugged stainless steel

- Safety Guarding

- Yes

- Components

- Off-the-shelf

- Controls

- Siemens or Allen Bradley

- Automation

- Servo drives

- Protection Rating

- IP54

- Carton handling

- Gentle handling

- Flap closing configuration

- One, two, or three flaps

- Flow configuration

- Straight-line or right-angle

- Changeover time

- Easy format changeover

- Automation level

- Servo drives / Siemens or Allen Bradley controls

- Adaptability

- Driven to adapt to random carton flow

- Cleaning method

- IP54 construction

- Cleanability

- Easy to clean stainless steel

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- 50–300 g/cm³

- Carton size range

- Min 50 mm x 80 mm x 25 mm, Max 225 x 300 x 200 mm

- Machine Footprint

- 1100 mm W x 2800 - 3500 mm L x 2000 mm H

- Weight

- 900 - 1300 kg

- Carton Size (Intermittent)

- Min

- Max

- 225 mm x 300 mm x 200 mm

- Construction Material

- Rugged stainless steel

- Air Pressure

- 6 bar (15–18 CFM at 90 PSI)

- Power Supply

- 6 - 12kVA

- IP Rating

- IP54 construction

- Infeed/outfeed conveyors

- Various styles

- Construction type

- Straight-line or right-angle

- Frame sizes

- Different sizes for large cartons

- Carton flap closing configuration

- One, two, or three flaps

- Control panel type

- Siemens or Allen Bradley controls

- Safety guarding

- Included

- Remote diagnostics

- Available

- Special electronics and voltages

- Available

- Washdown construction

- IP65