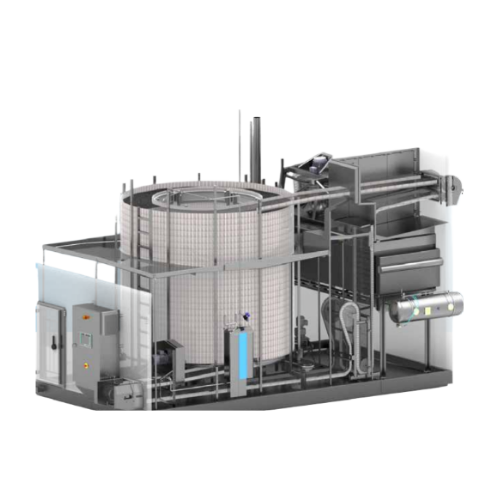

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, optimizing energy use with a 65% reduction in drive power, and maintaining high hygiene standards with a self-stacking stainless steel belt. Ideal for continuous and high-speed operations needing reliable performance and flexible configuration.

Efficiently Freezes, Chills, and Proofs Food Products

The Frigoscandia GYRoCOMPACT® 60 Spiral Freezer stands out with its reduced energy consumption, optimizing operations with a 65% reduction in drive power. Equipped with the FRIGoBELT® NOVA self-stacking belt, it ensures product hygiene and comes with a 10-year warranty. This freezer revolutionizes the processing of bakery goods, confectioneries, meats, and ready meals, handling up to 3,500 kg/hour. Its compact design incorporates high-efficiency fans and automatic lubrication, lowering oil consumption by 20%. The ProLINK® controls enable easy operation, while stainless steel evaporators guarantee enhanced heat transfer. The system supports different CIP levels, the LVS refrigeration system, and an Air Defrost feature for increased uptime. Tailored to fit into your production line, the GYRoCOMPACT® 60 adapts as a proofing system and offers a range of configurations and product height options, ensuring seamless integration into high-speed, continuous food processing lines.

Benefits

- Enhances product throughput with a capacity of up to 3,500 kg/hour.

- Lowers operational costs by reducing drive power consumption by 65%.

- Minimizes maintenance with a 20% reduction in oil usage via automatic lubrication.

- Improves energy efficiency with variable-speed fans and LVS refrigeration.

- Customizable to specific production needs, ensuring seamless integration into existing lines.

- Applications

- Seafood, Ready meals, Pasta, Bread, Bakery, Confectionery, Meat, Fruits, Nuts, Plant-based protein, Poultry

- End products

- Chocolate truffles, Baguettes, Roasted almonds, Beef patties, Tortellini, Frozen chicken breasts, Shrimp cocktail, Frozen berries, Microwavable lasagna, Tofu blocks, Frozen croissants

- Steps before

- Portioning, Slicing, Grinding, Mixing, Preparation

- Steps after

- Packing, Coating, Weighing, Bagging, Proofing

- Input ingredients

- raw poultry, raw meat, raw seafood, dough, fruits, nuts, plant-based protein, ready meal components

- Output ingredients

- frozen poultry, frozen meat, frozen seafood, frozen dough, frozen fruits, frozen nuts, frozen plant-based protein, frozen ready meals

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Capacity

- up to 3, 500 kg/hour

- Drive Power Reduction

- 65% reduction

- Belt Type

- FRIGoBELT® NOVA self-stacking

- Belt Rotation

- Clockwise (CR) or Counter Clockwise (CCR)

- Energy Consumption

- High efficiency fans

- Lubrication

- Automatic lubrication system

- Oil Consumption Reduction

- 20%

- User Controls

- ProLINK® user friendly controls

- Airflow

- Vertical airflow

- Heat Transfer

- Counter current heat transfer

- Product Height Configurations

- 65, 85, 105 mm

- Defrost System

- Air Defrost system (ADF)

- Refrigeration System

- LVS refrigeration system

- Cleaning Systems

- Three levels of CIP systems available

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- ProLINK® user-friendly controls

- Energy efficiency

- 65% reduction in drive power

- Cleaning method

- CIP system

- Drive mechanism

- FRIGoBELT®NOVA self-stacking belt

- Belt rotation direction

- Clockwise (CR) / Counter Clockwise (CCR)

- Cooling capacity

- Up to 3, 500 kg/hour

- Abrasion resistance

- Available

- Biological compatibility

- Available

- Cleanability

- Easy Clean

- Corrosive resistance (e.g. acids)

- Stainless Steel

- Density/particle size

- Wide Range

- Compact footprint

- 65% reduced drive power

- Machine footprint

- More compact design

- Vertical airflow

- Enhanced cooling efficiency

- Belt rotation

- Clockwise / Counter Clockwise

- Self-stacking belt

- FRIGoBELT® NOVA

- Maximum product height configurations

- 65, 85, 105 mm

- Enclosure panels

- Caulked for installation ease

- Belt material

- Stainless steel mesh

- Floor design

- Modular stainless steel sloped floor

- Control panel type

- ProLINK® user friendly controls

- Module configurations

- 3 product height configurations (65, 85, 105 mm)

- Refrigeration system

- LVS refrigeration system

- Cleaning system

- 3 levels of CIP systems