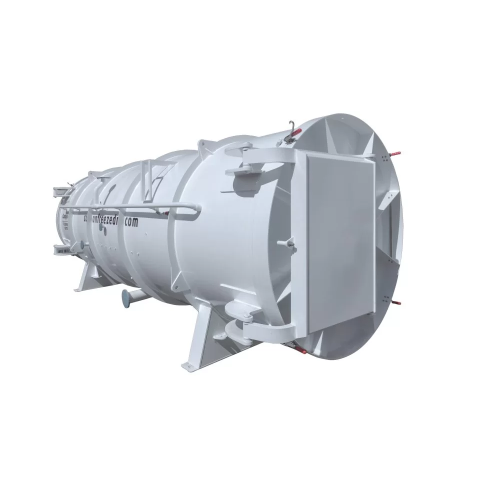

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale freeze drying solution, designed for efficient batch processing of biopharmaceuticals, food products, and more.

Efficiently Freeze Dries Large-Scale Batches

The FD1800GPC Industrial Freeze Dryer from Cuddon Freeze Dry is engineered to meet the demands of large-scale commercialization in sectors such as food and pharmaceuticals. This robust freeze dryer features an impressive 1,800kg ice capacity and a shelf area of 170.5m² distributed across 19 shelves, making it ideal for high-volume processing. Designed for efficient moisture removal through sublimation, it supports diverse applications ranging from biopharmaceuticals to baby food and supplements. The FD1800GPC operates with a peak power requirement of 214kW and offers potential heat energy recovery of 140kW, enhancing energy efficiency. With a temperature range of -35°C to 70°C, it ensures precise control, crucial for maintaining product integrity across various formulations. Its construction allows processing of solid, slurry, and cake product types, utilizing food-grade anodized aluminum trays. Versatile integration is facilitated by its separate plant skid and dual-chamber doors, accommodating diverse operational needs. The unit is constructed to comply with stringent industry standards, ensuring reliable performance in commercial drying operations.

Benefits

- Enhances processing efficiency with a large 1,800kg ice capacity, reducing operational time.

- Optimizes energy use, achieving significant energy recovery for cost-effective operation.

- Ensures precise product quality with a wide temperature control range, critical for sensitive applications.

- Facilitates high-volume production with extensive shelf space, increasing batch yield.

- Integrates seamlessly into existing operations with flexible plant skid design, minimizing installation complexity.

- Applications

- Vitamins, Supplements, Sauces, Liquid formulations, Snacks, Pet food, Nutraceuticals, Pharmaceutical powder, Cereals, Biopharmaceuticals, Enzymes, Sweets, Spices, Nuts, Baby food, Plant-based milk, Essential oils

- End products

- Protein powders, Vaccines, Cornflakes, Dog kibble, Fruit snacks, Lipase enzyme powder, Vitamin c tablets, Almond milk powder, Infant formula, Immunity-boosting supplements, Omega-3 capsules, Chocolate candies, Cough syrup, Roasted almonds, Tomato sauce, Lavender essential oil, Curry powder

- Steps before

- Loading wet product, Pre-cooling, Pre-freezing

- Steps after

- Unloading dried product, Post-drying inspection, Packaging, Storage

- Input ingredients

- wet product, wet material, high moisture content material

- Output ingredients

- dry product, freeze-dried product, 80% moisture removed product

- Market info

- Cuddon Freeze Dry is known for manufacturing high-quality freeze-drying equipment. The company specializes in engineered-to-order solutions, offering expertise in designing and building customized systems for diverse industrial applications.

- Ice capacity

- 1800 kg

- Shelf area

- 170.5 m²

- Doors

- 2 (one on each end)

- Observation ports

- Yes

- Average yield of dry product per cycle

- 360 kg

- Potential heat energy recovery

- 140 kW

- Peak power requirement

- 214 kW, 50 or 60 Hz

- Estimated energy consumption

- 1.5 kWh/kg

- Operational power consumption (Dry)

- 110 kW

- Ice condenser temperature

- -40°C

- Shelf temperature range

- -35°C to 70°C

- Shelf spacing

- 35 mm

- Product tray material

- Food grade anodised aluminium

- Number of product trays

- 336 per cycle

- Heating / cooling medium

- Temper 55

- Plant equipment

- Plant on separate skid

- Overall footprint

- 7.20m (L) x 2.80m (W) x 2.58m (H)

- Plant skid footprint

- 5.80m (L) x 2.00m (W) x 2.35m (H)

- Weight

- 33, 500 kg

- Product trays size

- 1025mm x 495mm x 20mm

- Batch vs. continuous operation

- Batch

- Automation level

- PLC-controlled

- Cooling / Heating medium

- Temper 55

- Energy efficiency

- 1.5 kWh/kg

- Food-grade material

- Food grade anodised aluminium

- Corrosion resistance

- -

- Cleanability

- -

- Temperature resistance

- -40°C to 70°C

- Biological compatibility

- -

- Chemical resistance

- -

- FDA materials

- Food grade anodised aluminium

- Overall footprint

- 7.20m (L) x 2.80m (W) x 2.58m (H)

- Plant skid footprint

- 5.80m (L) x 2.00m (W) x 2.35m (H)

- Weight

- 33, 500 kg

- Shelf area

- 170.5m2 on 19 shelves

- Shelf spacing

- 35mm

- Product tray size

- 1025mm x 495mm x 20mm

- Number of doors on product chamber

- 2 (one on each end)

- Number of product trays

- 336 per cycle (2 sets supplied)

- Control panel type

- Customizable HMI

- Integration possibilities

- PLC/SCADA systems