Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging lines with high-speed, versatile dosing and filling systems designed for seamless integration and precision in handling varied product shapes and sizes.

Doses and Fills Diverse Solid and Granular Products

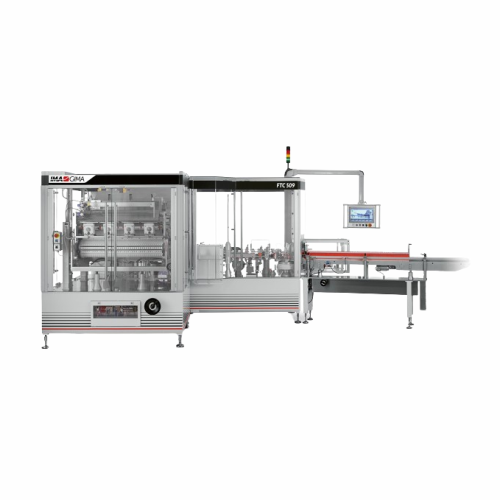

The FTC Series from IMA Group offers medium- to high-speed vertical dosing and filling machines ideal for diverse packaging needs across confectionery, nutraceutical, and food industries. These machines excel in handling a wide array of products, including capsules, tablets, and candies, with modular designs that allow for seamless integration into existing production lines. Utilizing flexible dosing systems like electronic counting and volumetric filling, the FTC Series accommodates various container types, ensuring precision and efficiency in every operation. With capacities tailored to meet high throughput, these machines prioritize energy efficiency and easy maintenance, featuring a compact design with full accessibility for quick format changeovers. Designed for compliance with industry standards, the FTC Series supports customizable options to fit specific production requirements.

Benefits

- Enhances production flexibility by accommodating various container shapes and sizes.

- Increases efficiency with seamless dosing and filling processes for wide-ranging product types.

- Simplifies operations with user-friendly design and quick format changeovers, minimizing downtime.

- Optimizes packaging accuracy, reducing product waste with precise dosing systems.

- Integrates smoothly into existing production lines for scalable and customizable operation solutions.

- Applications

- Dried fruit, Hard candies, Nutraceuticals, Confectionery, Liquorice, Gums, Coated sweets, Nuts, Tablets, Sweeteners, Capsules, Soft candies

- End products

- Gummy bears, Roasted almonds, Licorice sticks, Stevia packets, Coated chocolate candies, Dehydrated apricot slices, Chocolate bars, Multivitamin tablets

- Steps before

- Grinding, Mixing, Formulation

- Steps after

- Packing, Quality Control, End-of-Line Automation

- Input ingredients

- cartons, plastic containers, metal containers, bottles, tins, jars, capsules, tablets, hard candies, soft candies, gums, coated sweets, liquorice, sweeteners, nuts, dried fruit

- Output ingredients

- filled cartons, filled plastic containers, filled metal containers, filled bottles, filled tins, filled jars

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Speed

- 250–450 ppm (for cartons)

- Production Speed

- 105–300 ppm (for rigid containers)

- Container type - Cartons

- Cylindrical, square, irregular shape

- Container type - Rigid Containers

- Plastic, metal

- Closure Styles

- Dispenser, top opening, pressure or screw caps

- Dosing System

- Slat, electronic counting, volumetric, weighing

- Format Changeover

- Easy, operator-friendly with mechanical references

- Automation level

- PLC / SCADA

- Changeover time

- Quick and operator-friendly

- Batch vs. continuous operation

- Batch or Inline Continuous

- Cleaning method

- Manual

- Flexibility in closure styles

- Pressure or screw caps

- Container handling

- Cartons, bottles, tins, jars

- Product compatibility

- Capsules, tablets, candies, sweeteners, nuts

- Modular configuration

- Yes

- Abrasion resistance

- Yes

- Biological compatibility

- Applicable for food and nutraceuticals

- Cleanability

- Easy to clean with fully accessible design

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Handles a wide range of densities and particle sizes

- Container type

- Cartons, plastic, metal

- Product shapes handled

- Cylindrical, square, irregular

- Product types handled

- Capsules, tablets, candies, nuts

- Machine footprint

- Compact footprint

- Container compatibility

- Cartons, plastic and metal containers, including bottles, tins, jars

- Container shape

- Cylindrical, square, irregular

- Closure styles

- Dispensers, top opening, pressure caps, screw caps

- Modular configuration

- Yes

- Accessibility

- Fully accessible equipment design

- Ergonomic design

- Ergonomic operating position

- Control panel type

- Touchscreen HMI

- Container compatibility

- Cartons, bottles, tins, jars

- Shape compatibility

- Cylindrical, square, irregular

- Closure flexibility

- Dispensers, top opening, pressure or screw caps

- Modular design

- Fully accessible, easy implementation

- Dosing systems

- Slat, electronic counting, volumetric, weighing systems