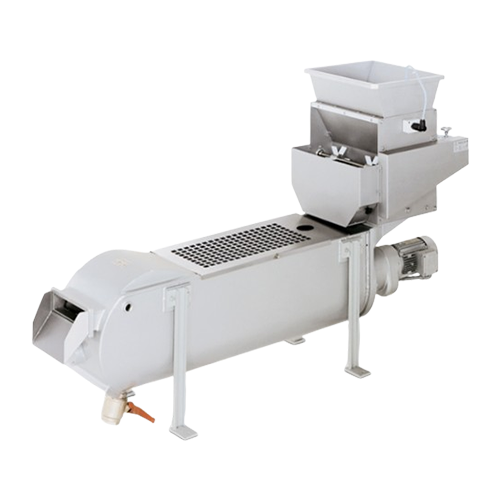

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixing and dosing functions for precise ingredient blending, ensuring consistent quality in every batch.

Continuously Mixes and Doses Ingredients

The Contimixer SMK from SOLLICH is a high-speed mixer and dosing system designed to optimize ingredient distribution in continuous production lines for food manufacturers. Featuring a modular design, it integrates seamlessly into existing setups, enhancing efficiency in processes like mixing, dosing, and admixing. Ideal for producing chocolate candy bars, cereal bars, and pralines, this versatile equipment operates with high throughput, handling a variety of product types from powders to solids. Its automation capabilities are supported by PLC controls, ensuring precise dosing and minimal waste. The Contimixer SMK is constructed from durable materials, ensuring longevity and resistance to wear in demanding environments. With options for custom engineering, it meets diverse production needs while maintaining compliance with industry standards for food safety and quality.

Benefits

- Enhances production efficiency with continuous high-speed mixing and dosing capabilities.

- Minimizes ingredient waste through precise automated dosing control.

- Integrates seamlessly into existing lines, reducing installation time and cost.

- Constructed with durable materials for long-lasting performance in demanding environments.

- Supports a diverse range of product applications, expanding production flexibility.

- Applications

- Biscuits, Brittle bars, Dragees, Pralines, Decorative articles, Fruit bars, Chocolate products, Cereal bars, Nuts, Candy bars, Sweets, Ice cream, Protein bars

- End products

- Chocolate truffles, Granola bars, Yogurt-covered raisins, Roasted almonds, Shortbread biscuits, Sugar-coated sweets, Chocolate pralines, Vanilla ice cream, Date fruit bars, Whey protein bars, Chocolate candy bars, Chocolate decorations, Peanut brittle bars

- Steps before

- Drying, Grinding

- Steps after

- Coating, Packing

- Input ingredients

- dry materials, ingredients for chocolate products, flavour additives, colour additives

- Output ingredients

- chocolate products, chocolate bars, cereal bars, protein bars, fruit bars, brittle bars, formed chocolate items

- Market info

- Sollich is known for manufacturing engineered-to-order equipment for the confectionery industry, particularly chocolate processing and enrobing machines. They have a strong reputation for innovation, quality, and tailored solutions to meet specific customer requirements.

- Capacity

- 100–5000 kg/h

- Automation

- PLC-controlled

- Cleaning method

- CIP / SIP / manual

- Mixing type

- Continuous/Batch

- Dosing type

- Gravimetric / Volumetric

- Energy Usage per Batch

- 5–20 kWh

- Temperature control

- ±1°C

- Feed type

- Dry / Wet

- Feed rate

- 50–1000 kg/h

- Working mechanism

- Continuous mixing

- Integrated steps

- Mixing and dosing

- CIP principles

- Available

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC / SCADA

- Energy efficiency

- High

- Changeover time

- Minimal

- Cleaning method

- CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Continuous

- Control panel type

- Touchscreen

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / ERP

- Discharge method

- Auger / Gravity

- Compact footprint

- Yes

- Automation level

- PLC / Manual

- Modular design

- Yes