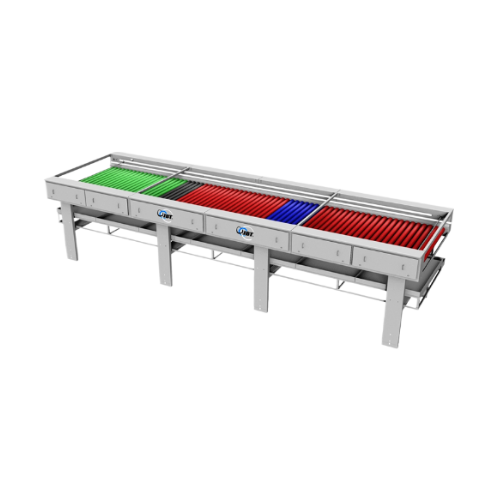

Brush bed system for fresh produce cleaning and waxing

Optimize your fresh produce processing with this advanced brush system, designed to efficiently clean and wax fruits and nuts, ensuring high-quality results while maintaining food safety and operational efficiency.

Cleans and Waxes Fresh Produce Effortlessly

The Brush Bed System from JBT FoodTech offers a versatile solution for cleaning and waxing operations within the fresh produce industry. Engineered with multiple brush configurations, this equipment is tailored to handle a variety of fruits and nuts, such as apples, oranges, walnuts, and berries. Its robust design incorporates easy-to-maintain stainless steel A-frames and a brush drive system with a #60 chain and steel sprockets, ensuring durability and reliability in continuous production lines.

The system’s automated operation integrates smoothly into existing processing setups, minimizing manual intervention and optimizing workflow. With adjustable configurations, the Brush Bed System supports customization according to specific product and process requirements, including application systems for waxes and sanitizers. It features a clean-in-place (CIP) function for efficient maintenance, reducing downtime and contamination risk.

Operating at 230/460 VAC, 3-phase, 60 Hz, the system enhances energy efficiency with its optimized motor control, making it a cost-effective option for large-scale food processing companies and fresh produce facilities. This equipment upholds rigorous food safety standards with its use of food-grade materials and construction designed to withstand harsh processing environments.

Benefits

- Enhances product quality by efficiently cleaning and waxing diverse fruits and nuts.

- Integrates seamlessly into automated production lines, reducing labor costs and enhancing efficiency.

- Minimizes downtime with quick and thorough clean-in-place maintenance.

- Ensures long-term reliability with durable stainless steel construction, reducing maintenance frequency.

- Customizable configurations optimize processing for various product types and facility needs.

- Applications

- Nuts, Fresh produce, Fruits

- End products

- Berries, Pears, Apples, Oranges, Walnuts, Lemons, Almonds, Grapes

- Steps before

- Sorting, Pre-washing

- Steps after

- Waxing, Sanitizing, Packaging

- Input ingredients

- fresh produce, fruits, nuts

- Output ingredients

- cleaned produce, waxed produce

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Electrical Requirements

- 230/460 VAC, 3-Phase, 60 Hz

- Pin Range

- 8-72

- Width

- 2-7 feet

- Drive System

- #60 chain and steel sprockets

- Spindle Construction

- Aluminum idle pin hubs with 1″ stainless steel idle shaft

- Material

- Heavy duty 11-gauge stainless steel with #4 finish

- Automation

- Automated clean-in-place system

- Working mechanism

- Brush Bed System

- Integrated steps

- Cleaning, Waxing

- CIP principles

- Automated clean-in-place system

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Changeover time

- Quick change brush mount

- Density/particle size compatibility

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product size

- Varied

- Machine footprint

- Adjustable width 2-7 feet

- Brush Configuration

- Multiple configurations

- Material

- Heavy duty 11-gauge stainless steel with #4 finish

- Drive System

- Brush drive system with #60 chain and steel sprockets

- Spindle

- Aluminum idle pin hubs with 1" stainless steel idle shaft

- Cleaning system track

- UHMW food grade

- Legs and Feet

- Heavy duty stainless steel

- Fruit Guards

- Stainless steel

- Brush configuration

- Multiple configurations available

- Brush size

- Available in multiple sizes

- Water removal configuration

- Customized options available

- Application system

- Wax, sanitizers, etc.

- Automated cleaning

- Clean-in-place system available

- Drive arrangement

- Multi-drive arrangement available

- Width

- 2-7 feet

- Pin Range

- 8-72

- Flipper bar and frame

- Stainless steel