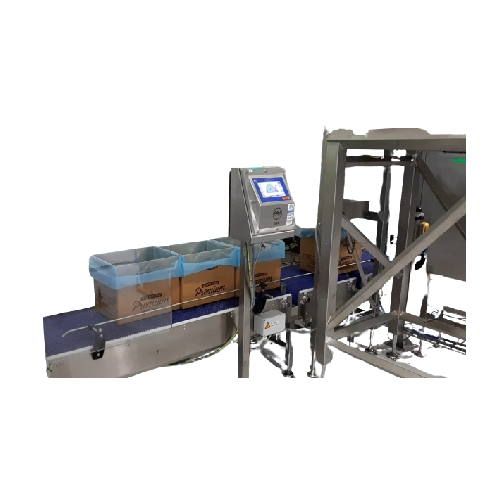

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from dried fruits to frozen berries, enhancing productivity and accuracy in your packaging line.

Weighs and Packs Solid Products Accurately

The Linear Weigh Filler from Niverplast is a state-of-the-art solution designed to efficiently handle the weighing and packing of solid products such as dried fruits, nuts, and frozen berries. This equipment is engineered for precision, employing a self-learning system to maintain high accuracy across continuous operations, producing up to 15 cartons per minute. Its robust construction in stainless steel ensures durability and ease of maintenance, making it ideal for food packaging environments. With an intuitive touchscreen for simple operation and integration into automated packaging lines, it supports seamless workflow. Notably, the machine allows for big bag filling and easy adaptation to various box sizes. Suitable for diverse industries like food, packaging, and e-commerce, the Linear Weigh Filler meets rigorous production demands with energy efficiency and customization options for specific production needs.

Benefits

- Enhances production efficiency by accurately weighing and packing up to 15 cartons per minute.

- Minimizes labor intervention through a self-learning system that auto-adjusts to different products.

- Ensures long-term reliability with durable stainless steel construction.

- Facilitates easy maintenance and cleaning, reducing overall downtime.

- Integrates seamlessly into existing automated packaging lines for continuous operation.

- Applications

- Candy, Frozen fruits, Nuts, Solid products, Raisins, Dried fruits, Dates

- End products

- Jelly beans, Frozen berries, Dried apricots, Sultana raisins, Almonds, Medjool dates

- Steps before

- Product preparation, Box preparation, Bag placement

- Steps after

- Box sealing, Labeling, Palletizing, Quality control

- Input ingredients

- boxes, dried fruits, nuts, candy, solid products, frozen fruits, dates, raisins

- Output ingredients

- filled boxes, accurate weights, packaged goods, bags in boxes

- Market info

- Niverplast is known for innovative packaging solutions, specializing in industrial engineered-to-order equipment for bag-in-box systems, tray handling, and carton erecting machinery, with a strong reputation for quality and reliability in the packaging industry.

- Speed

- Up to 12-15 cartons per minute

- Material

- Completely executed in stainless steel

- Automation

- Self-learning system

- Accuracy

- High accuracy

- Filling Method

- Filling by weight

- Product Compatibility

- Dried fruits, nuts, candy, solid products, frozen fruits

- Filling option

- Big bag filling (Optional)

- Changeover time

- Automatic with self-learning system

- Automation level

- Interactive and intuitive touchscreen control

- CIP/SIP

- Easy access for manual cleaning

- Batch vs. continuous operation

- Batch operation

- Cleaning method

- Manual

- Integration Capability

- Fits into existing packaging lines

- Filling Mechanism

- Filling by weight

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material Construction

- Stainless Steel

- Machine Footprint

- Compact

- Box Size Compatibility

- Wide Variety

- Control Panel Type

- Interactive touchscreen

- Discharge Method

- Box Discharge

- Control panel type

- Interactive and intuitive touchscreen

- Big bag filling option

- Available

- Construction material

- Stainless steel

- Maintenance access

- Easy access for maintenance and cleaning

- Self-learning system

- Included