Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed to efficiently fill and seal a variety of pouch sizes, ensuring product integrity and maximizing throughput for demanding production environments.

Fills and Seals Premade Pouches

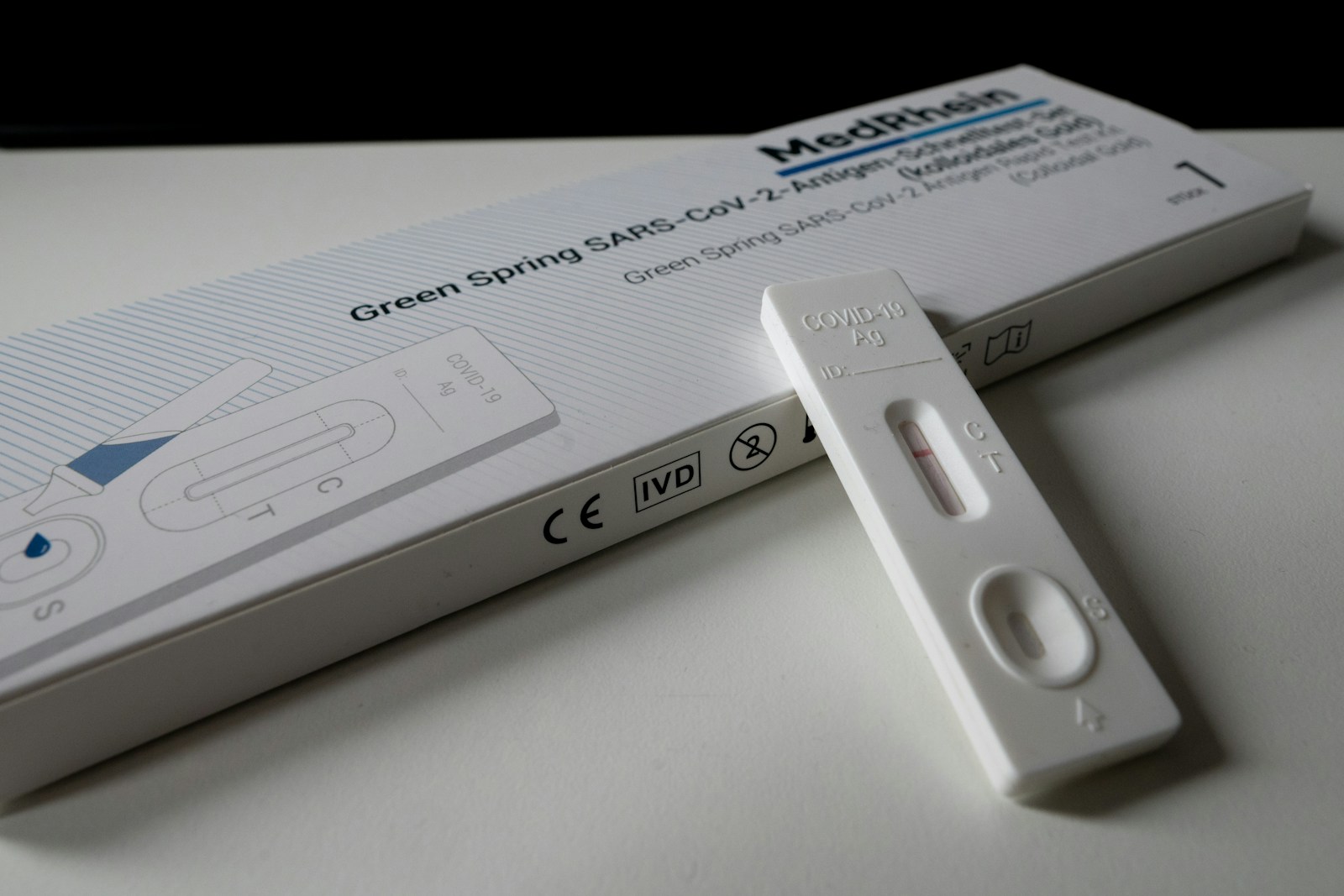

The Viking-8S-320 from Viking Masek is an automatic rotary premade pouch machine designed to enhance efficiency in diverse industrial packaging operations. Featuring an 8-station configuration, this machine excels in filling and sealing applications for a wide range of products including powders, liquids, and solids. Its production process involves precise filling and sealing at speeds up to 50 cycles per minute, with a bag size accommodating up to 350mm wide pouches. Ideal for industries such as food, beverage, health, and contract packaging, typical end-products include granola, ground coffee, gummy bears, and medical testing kits.

The machine is PLC-controlled with a user-friendly touch screen, allowing seamless integration into existing production lines. It features an automatic deoxidizer feeding station and a two-step sealing process to guarantee product integrity. Customization options include integration with multi-head scales, volumetric fillers, and auger fillers. With safety and quality assurance as priorities, it offers comprehensive features such as pouch presence detection, bag deflation, and a robust quality control system capable of checkweighing and X-ray inspection. The Viking-8S-320 is engineered for endurance with a durable welded steel frame and IP65 or IP66 washdown capability for easy maintenance, meeting all necessary compliance and certification standards.

Benefits

- Enhances operational efficiency by seamlessly integrating with existing production lines.

- Minimizes product loss with precise filling and sealing technologies.

- Reduces labor costs through user-friendly, PLC-controlled automation.

- Ensures product integrity with advanced quality control measures.

- Simplifies maintenance and cleaning with durable, washdown-capable construction.

- Applications

- Contract packaging, Treats, Medical devices, Snacks, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Powders, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Vegetables, Poultry, Medical

- End products

- Vitamin tablets, Soft gel capsules, Potato chips, Protein powder, Jasmine rice, Salmon fillets, Chicken breast, Frozen peas, Frozen berries, Covid-19 test kits, Bandages, Cheddar cheese, Dental treats, Cornflakes, Organic peanut butter, Syringes, Instant mashed potatoes, Macaroni, Dairy-free milk, Granola, Black beans, Ground coffee, Almonds, Muesli base flakes, Gummy bears, Tomato juice, Cbd oil, Dry cat food

- Steps before

- Product preparation, Mixing, Weighing, Quality inspection

- Steps after

- Sealing, Cooling, Quality control, Product packaging, Labeling, Shipping

- Input ingredients

- powders, food products, multi-head scales, volumetric fillers, auger fillers

- Output ingredients

- premade pouch, bags, sealed bags, filled pouches

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 50 CPM

- Bag Size

- Min 160 mm W x 150 mm L, Max 320 mm W x 420 mm L

- Automation

- PLC-controlled

- Bag Gripping Range

- 160-320mm

- Power Supply

- 480 V / 3 Ph / 50/60 Hz / 35 A

- Compressed Air Usage

- Approx. 600NL/min, 5~6kgf/cm2

- Cooling Station

- For liquid products

- Sealing Temperature

- Two step sealing process

- Pouch Presence Detection

- No filling, no sealing

- Filling Integration

- Multi-head scales, volumetric fillers, auger fillers

- Working Mechanism

- Automatic Rotary Premade Pouch Machine

- Integrated Steps

- Filling, Sealing, Cooling, Deoxidizer Feeding

- Automation Level

- PLC-controlled

- Bag Deflation Method

- Wire guide or push bars

- Product Filling Integration

- Multi-head scales, Volumetric fillers, Auger fillers

- Sealing Process

- Two-step sealing

- Pouch Presence Detection

- No filling, No sealing

- Batch vs. Continuous Operation

- Batch (up to 50 CPM)

- Cooling Station

- Available for liquid products

- Changeover Time

- Not Specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Powder handling

- Yes

- Foaming products

- No

- Machine footprint

- N/A

- Bag size

- Min

- Frame material

- Welded steel

- Number of stations

- 8

- Cooling station

- Included for liquid products

- Control panel type

- Touch screen operation

- Frame material

- Highly durable welded steel

- Zipper opening device option

- Available

- Safety guards

- Fully interlocked

- Pouch presence detection

- No filling, no sealing

- Product filling options

- Integrated with scales and fillers

- Date coding option

- Emboss, hot stamp, inkjet, thermal transfer

- Dust management

- Dust suction nozzles and dust collector

- Bag rejection system

- Available

- Stand-up discharge

- Available