Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed and outfeed systems, ensuring seamless material handling and reducing labor costs while enhancing efficiency across packaging operations.

Transports and Elevates Products in Packaging Lines

Viking Masek’s Infeed and Outfeed Conveyor Systems seamlessly integrate with packaging lines, offering efficient product handling for various industries, including food, beverage, and medical supplies. These systems feature bucket elevators for gentle vertical transport and vacuum loaders for granular products, ensuring minimal product loss. With screw and incline conveyors, the systems suit a wide range of product types, from powders to solids. Fully automated and capable of high-speed operation, these systems reduce labor costs and enhance processing efficiency. Designed with customizable options, they fit specific line requirements and meet relevant safety and quality standards.

Benefits

- Enhances operational efficiency by automating product transport, reducing manual labor demands.

- Accommodates a wide range of product types, from powders to solids, ensuring versatile applications.

- Integrates seamlessly with existing packaging lines, minimizing installation and transition time.

- Supports high-speed operations, boosting production throughput without sacrificing product integrity.

- Customizable configurations ensure compatibility with specific production line requirements and industry standards.

- Applications

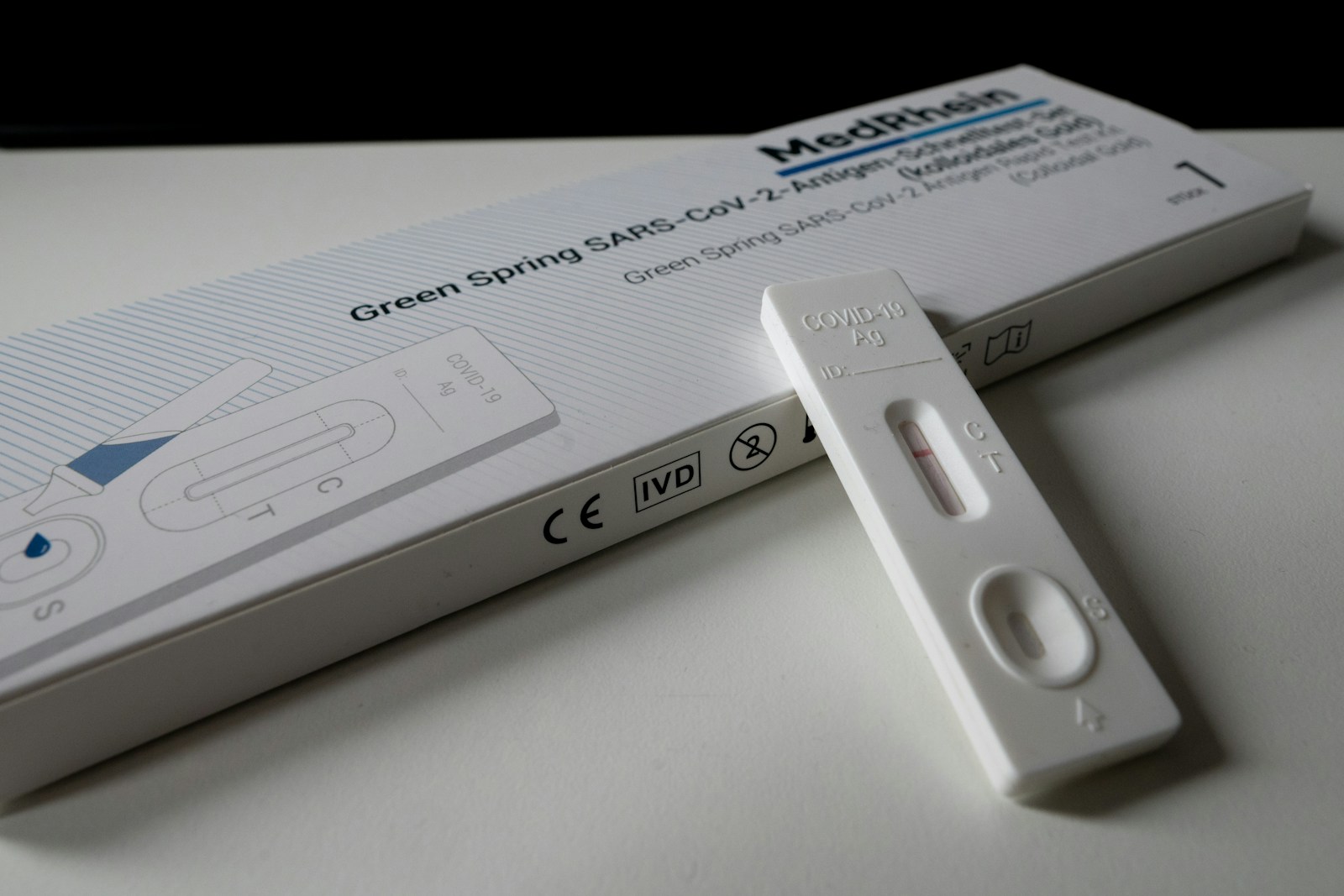

- Contract packaging, Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Powders

- End products

- Dog biscuits, Spaghetti, Canned beans, Vitamin supplements, Sliced carrots, Protein powder, Gluten-free bread, Fruit juice, Chicken nuggets, Jasmine rice, Granola bars, Detergents, Almond milk, Espresso pods, Frozen peas, Croissants, Covid-19 test kits, Instant coffee, Chopped lettuce, Syringes, Cleaning wipes, Roasted almonds, Smoked salmon, Surgical gloves, Gummy bears, Trail mix, Gel capsules, Cannabis-infused gummies, Chocolate bars, Organic cheddar cheese, Pet kibble

- Steps before

- Bulk Product Transport, Material Elevation, Granular or Powder Product Loading

- Steps after

- Downstream Processing, Finished Bag Transport, Product Packing

- Input ingredients

- bulk product, fragile chips, sticky gummies, granular products, powder products, bulk powder, granular materials

- Output ingredients

- finished bags, processed products, packaged items

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Automation

- Fully automated

- Infeed system

- Bucket elevators, Vacuum loaders, Incline conveyors, Screw conveyors

- Outfeed system

- Automated conveyor

- Product handling

- Gentle and reliable

- Capacity

- Based on application

- Integration

- Turnkey integrated packaging solutions

- Operation

- Manual / Auto

- Speed

- Dependent on product and application

- Transport mechanism

- Conveyor systems

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC controlled

- Changeover time

- Minimal

- Product transport method

- Bucket elevator, Vacuum loader, Incline conveyor, Screw conveyor

- Abrasion resistance

- Yes for bulk products like chips and gummies

- Cleanability

- Smooth surfaces allow easy cleaning

- Corrosive resistance (e.g. acids)

- Not suitable for corrosive agents

- Density/particle size

- Suitable for granular and powder products

- Fragility

- Appropriate for fragile products like chips

- Stickiness

- Handles sticky products like gummies

- Flowability

- Suitable for free-flowing products

- Discharge method

- Belt / Roller / Chain conveyor

- Infeed method

- Bucket elevator / Vacuum loader / Screw conveyor

- Machine footprint

- Variable based on configuration

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Compatible with existing systems

- Infeed options

- Bucket elevators, Vacuum loaders, Incline conveyors, Screw conveyors

- Outfeed options

- Conveyor systems

- Automation level

- Fully automated