Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable robotic system designed to streamline high-speed operations, reduce manual labor, and ensure precise handling of diverse items from frozen pastries to pharmaceutical capsules in continuous production environments.

Automates Product Handling and Packaging Processes

The Syntegon Robotic Pick and Place Platform (RPP) offers a game-changing solution for diverse industries seeking to advance their packaging operations. This modular platform excels in automating product handling and placement with precision and efficiency.

Using integrated delta robots, the RPP system provides seamless product loading into trays or cartons, capable of achieving up to 140 picks per minute per robot, optimizing high-speed environments. Its design supports applications across pharmaceuticals, bakery products, confectionery, dairy, and more, enhancing operations from ampoules to chocolate bars.

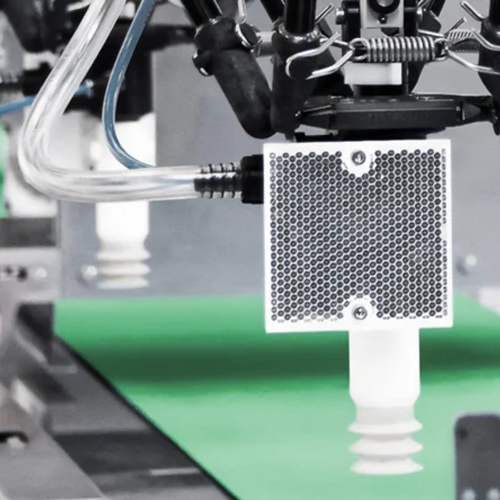

With its compact footprint, the RPP is PLC-controlled, supporting remote monitoring and smart interface integration for scalable capacity adjustments. Its construction in stainless steel offers superior hygienic operations and compliance with rigorous industry standards, including IP65 protection for wash-down scenarios. The platform’s vision-guided inspection technologies ensure tight quality control, identifying and removing any defective products in the process.

Syntegon’s RPP system includes quick-change end-of-arm tooling for format flexibility, supporting gentle and safe product handling while reducing contamination risks. It simplifies cleaning with its open-channel, self-draining design, paired with optional CIP systems. Custom configurations and engineering support are available to tailor the platform to your specific production demands, ensuring streamlined integration into existing production lines.

Benefits

- Enhances production efficiency by reducing manual handling and increasing line speed.

- Ensures high product quality with vision-guided inspection and precise robotic kinematics.

- Minimizes operational footprint with modular and scalable design, allowing flexible line configuration.

- Promotes hygienic operations with easy-to-clean stainless steel construction and IP65 compliance.

- Offers seamless integration into existing systems, supporting a wide range of applications and product formats.

- Applications

- Biscuits, Snacks, Granules, Noodles, Chocolate, Bakery products, Functional sweets, Cookies, Liquid food, Nutrition products, Fresh food, Health products, Bars, Pasta, Pet food, Chilled food, Nuts, Rice, Pharmaceuticals, Frozen food, Nutraceuticals, Confectionery, Cereals, Crackers, Powders, Dairy products

- End products

- Energy bars, Filled chocolates, Protein shakes, Potato chips, Noodles packs, Nutritional powders, Roasted peanuts, Toaster pastries, Cooked pasta dishes, Granola bars, Breakfast cereal flakes, Vials, Extruded fruit leather, Dog food pellets, Sugar-free gummies, Cartridges, Ice cream, Granulated spice blends, Yogurt, Capsules, Syringes, Candy, Frozen vegetables, Instant rice, Cat treats, Multivitamins, Fresh salads, Almond snacks, Frozen pastries, Ready-to-drink beverages, Packed fresh vegetables, Ampoules, Herbal supplements, Chocolate bars

- Steps before

- Product Handling, Product Feeding, Dosing

- Steps after

- Inspection, Capping, Coding, Tray Loading, Cartoning, Case Packing

- Input ingredients

- bakery products, frozen pastries, extruded fruit leather, fruit bars, confectionery items, chocolate bars, sachets, stickpacks, capsules, syringes, vials, fresh food, chilled food, snacks, nuts

- Output ingredients

- packaged bakery goods, packaged pastries, packaged fruit leather, packaged fruit bars, packaged confectionery, packaged chocolate bars, packaged sachets, packaged stickpacks, filled capsules, filled syringes, filled vials, sealed and packaged fresh food, packaged snacks, packaged nuts

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Pick rate per robot

- Up to 140 picks per minute

- Automation level

- Fully automated

- Accuracy

- High position accuracy

- Capacity

- Modular scalability

- Vision system

- 2D HD-color vision / Optional 3D AI-based vision

- Robot axes

- 4 or 5 axis delta robots

- Product handling

- Flat or on-edge loading

- Inspection technology

- 2D and 3D inspection

- Construction material

- Stainless steel, IP65 compliant

- Footprint

- Compact footprint

- Cleaning capability

- Wash-down construction optional

- Interface

- Smart interfaces

- Format changes

- Tool-less format changes

- Control system

- PLC-controlled

- Automation level

- PLC / Fully automated

- Batch vs. continuous operation

- Continuous

- Changeover time

- Fast, tool-less

- CIP/SIP

- CIP

- Cleaning method

- CIP

- Modular design

- Scalable platform design

- Flexibility

- High product and pack style flexibility

- Compact footprint

- Efficient use of production floor space

- Hygienic design

- Walk-in access, stainless steel, IP65

- Product handling

- Vision-guided, precise product handling

- Pick rate

- Up to 140 picks per robot per minute

- Inspection technology

- 2D, 3D vision inspection

- Product loading options

- Flat or on-edge

- End-of-arm tooling

- Fast, tool-less changeover

- System integration

- Seamless integration into existing systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Control panel type

- Touchscreen / PLC

- Discharge method

- Flat or on-edge loading

- Construction Material

- Stainless steel, IP65-compliant

- Control panel type

- HMI / Touchscreen

- Modular design

- Scalable platform design

- Integration possibilities

- Smart interfaces for additional robot capacity

- End-of-arm tooling

- Click systems with overload supervision

- Vision system integration

- Integrated 2D and 3D inspection technology

- Transport module

- Flexible carton and tray transport module

- Self-tracking belt design

- Automatic tension control