High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed packaging system, featuring flexible material options for sustainable, efficient production of sweets, nuts, and snacks.

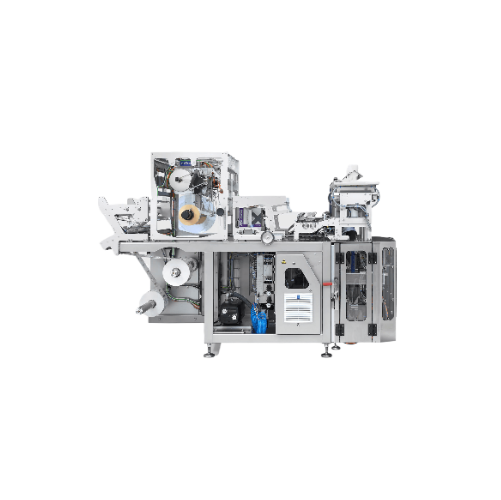

Packs, Labels, and Seals Snack Products

The GEA SmartPacker TwinTube, engineered by GEA, is a high-speed vertical form fill and seal machine designed to maximize production efficiency for food packaging companies. With a production capacity of up to 500 bags per minute, this system excels at handling a variety of snack and confectionery products, including candy, chips, nuts, and dried fruits. Its modular design allows seamless integration into existing production lines, while its ability to process both mono-material and paper-based bags aligns with sustainability goals. The patented open-machine design facilitates easy maintenance and adjustments, while automatic web tracking ensures operational consistency. Reliable and efficient, the TwinTube’s reinforced sealing technology supports diverse packaging materials, contributing to reduced costs and better packaging quality.

Benefits

- Maximizes packaging speed with up to 500 bags per minute, increasing production efficiency.

- Enhances sustainability by supporting mono-material and paper-based bag options.

- Reduces maintenance time with a user-friendly open-machine design and automatic web tracking.

- Lowers operational costs through efficient material usage and minimal downtime.

- Ensures consistent packaging quality with precise labeling and product-in-seal detection.

- Applications

- Dried fruit, Candy, Savory snacks, Nuts, Small cookies

- End products

- Oatmeal cookies, Gummy bears, Chocolate chip cookies, Hard candies, Raisins, Tortilla chips, Potato chips, Mixed nuts, Dried apricots, Cashews, Almonds

- Steps before

- Weighing, Sorting, Mixing, Feeding

- Steps after

- Sealing, Labeling, Cartoning, Palletizing

- Input ingredients

- candy, savory snacks, nuts, small cookies, dried fruit, mono material, paper based bags, traditional film bags

- Output ingredients

- pillow bags

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Bag width (min./max.)

- 60/160 mm

- Maximum bag weight

- 0.2 kg

- Maximum speed

- up to 500 bags/min

- Equipment dimensions H x W x D

- 1672 x 1611 x 2755 mm

- Bag type

- Pillow bags

- Material type

- Mono material or paper-based bags

- Sealing technology

- Reinforced

- Automation

- Automatic web tracking

- Product-in-seal detection

- Automatic

- Format change

- Quick, simple, no tools

- Modular design

- Future-proof

- Labeling unit speed

- up to 180 labels/min

- Label width

- 150 mm on each side

- Bag length control

- Monitored film transport and jaw movement

- Production output

- Up to 500 bags/min

- Bag width range

- 60–160 mm

- Automation level

- Automatic production cycles

- Format changeover time

- Quick and tool-free

- Sealing technology

- Reinforced, flexible sealing

- Material compatibility

- Mono material and paper bags

- Product-in-seal detection

- Automatic detection system

- Web tracking

- Automatic adjustment

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Products handled

- Candy, savory snacks, nuts, small cookies, dried fruit

- Machine footprint

- 1672x1611x2755 mm

- Bag width (min./max.)

- 60/160 mm

- Maximum bag weight

- 0.2 kg

- Compact footprint

- Yes

- Discharge method

- Not specified

- Control panel type

- Not specified

- Control panel type

- PLC-based

- Integration possibilities

- GEA TiroLabel integration

- Modular design

- Future-proof modular design for easy upgrades

- Bag type compatibility

- Mono material, paper-based bags

- Format change flexibility

- Quick, tool-free format changes

- Labeling unit

- GEA TiroLabel unit for precise labeling