Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures that ensure stabilization, allow easy access for maintenance, and facilitate cleaning and changeovers.

Stabilizes and Provides Access to Packaging Lines

Viking Masek’s Industrial Support Structures are engineered to enhance your packaging line’s stability and provide safe access for maintenance and cleaning. These structures support a variety of applications, including food, beverage, and medical product packaging. By incorporating ladders, platforms, and mezzanines, they facilitate seamless access to machine components, ensuring minimal downtime during maintenance and changeovers. Designed for high compliance and safety standards, these structures reduce fall risks and integrate smoothly into existing systems. Available with customizable options to suit specific environmental and operational needs, they are ideal for operations managing solids, liquids, powders, and granules in continuous or manual processes.

Benefits

- Enhances safety by providing secure access to all packaging line components.

- Minimizes operational downtime with quick maintenance and changeovers.

- Customizable for diverse industrial needs, ensuring seamless integration.

- Reduces injury risk with built-in safety features.

- Supports various product types, increasing operational flexibility.

- Applications

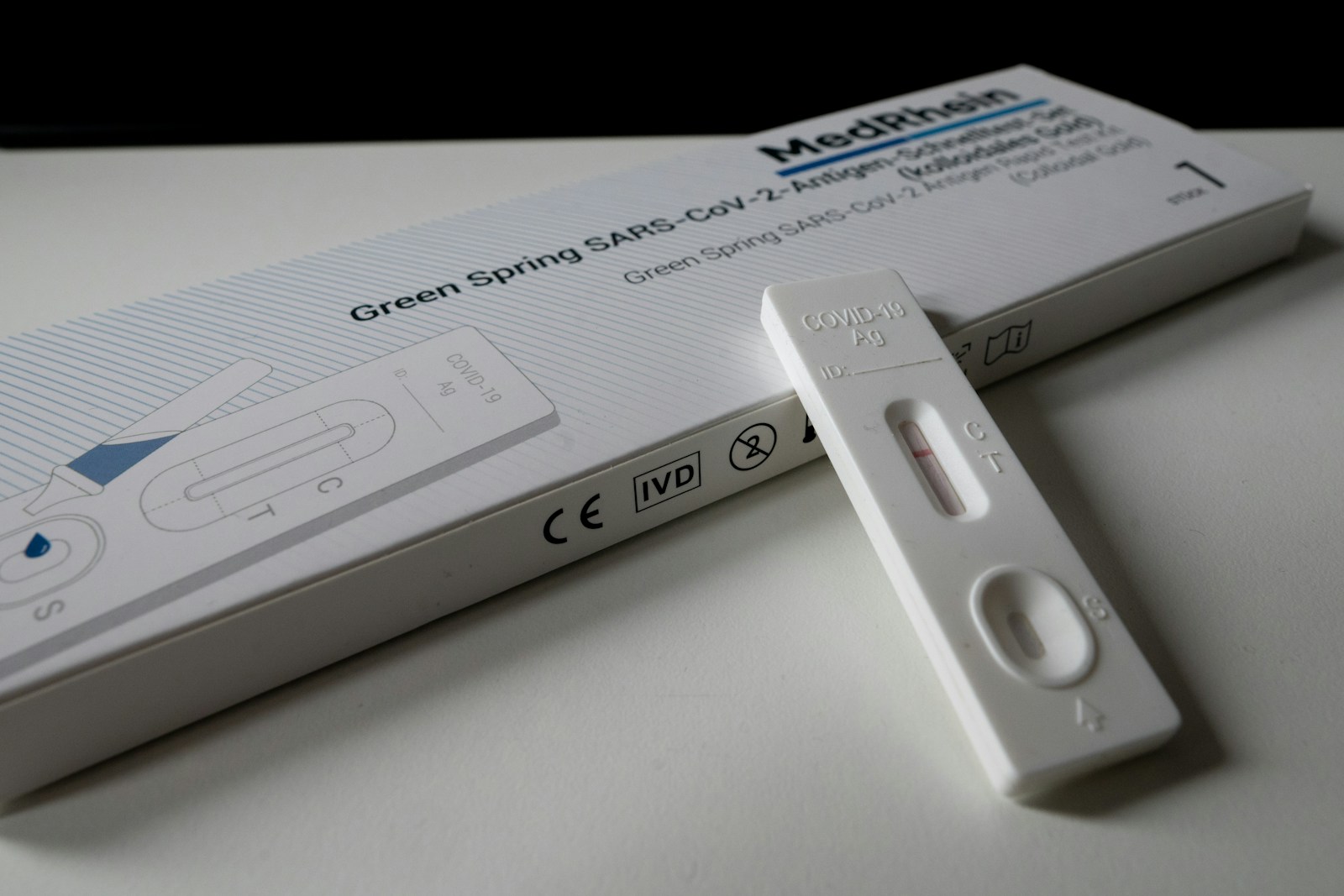

- Contract packaging, Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Powders, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Vegetables, Poultry, Medical

- End products

- Spaghetti, Dog kibble, Carrot slices, Potato chips, Protein powder, Jasmine rice, Kidney beans, Salmon fillets, Vitamin d tablets, Chicken breasts, Frozen peas, Coffee beans, Croissants, Covid-19 test kits, Cheddar cheese, Cornflakes, Syringes, Milk, Granola, Organic granola bars, Surgical masks, Juice, Cat treats, Almonds, Muesli base flakes, Cannabis oil, Gummy bears, Apples, Fish oil capsules, Mixed nuts

- Steps before

- Packaging Line Setup, Loading and Unloading Materials, Machine Calibration

- Steps after

- Cleaning, Maintenance, Changeovers, Inspection

- Input ingredients

- packaging line components, cereal, nuts, snacks, fresh fruit, vegetables, liquids, meat, poultry, fish, pet food, candy, pasta, beans, rice, cheese, bakery products, pills, capsules, medical devices, medical testing kits, natural foods, organic foods, non-food products

- Output ingredients

- packaged food, packaged beverage, packaged powders, packaged meat, packaged pet treats, packaged candy, packaged pasta, packaged rice, packaged natural foods, packaged medical supplies

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Support Structure Design

- Use of ladders and platforms

- Access Level

- All levels and areas of the packaging line

- Safety Features

- Built-in safety measures

- Stabilization

- Packaging system components

- Structure Type

- Mezzanines and support structures

- Maintenance Access

- Quick and easy cleaning and maintenance

- Risk Reduction

- Reduces risk of falls and injuries

- Working Mechanism

- Stabilization, Access Platforms

- Integrated Steps

- Maintenance, Cleaning, Changeovers

- Safety Measures

- Fall and Injury Prevention

- Cleaning Method

- Manual

- Batch vs. Continuous Operation

- Complementary to Batch or Continuous Systems

- Accessibility

- Maximum Access to Machine Components

- Maintenance adaptability

- Easy component access

- Stability points

- Key stabilization points

- Access method

- Ladders and platforms, mezzanines

- Safety features

- Integrated safety measures

- Support structure type

- Support structures, backbone of packaging line

- Support structure type

- Ladders and platforms

- Access method

- Mezzanines and platforms

- Stability features

- Key stability points

- Safety features

- Built-in safety measures

- Maintenance access

- Maximum access for cleaning and maintenance

- Integration possibilities

- Ancillary support for packaging line components