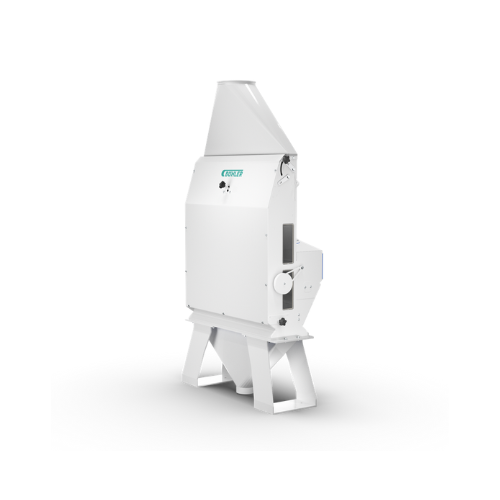

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granular products, ensuring optimal granule purity and streamlined processes in your production line.

Efficiently Separates and Cleans Granular Products

The Aspiration Channel MVSU from Bühler is a modular grain cleaning solution that excels in separating lighter particles from granular products such as cornmeal and whole wheat flour. Utilizing a finely-tunable air valve matched with a sealed partition wall, this equipment enables precise separation, enhancing end-product quality. It’s perfect for integration into grain milling and food processing lines, handling a variety of applications like cocoa powder production and roasted coffee beans sorting. The MVSU supports continuous operation and features a hygienic design using FDA-approved materials to ensure maximum food safety. For ease of maintenance, it offers multiple adjustment options and a residual emptying function for easy cleaning, while accommodating varying production demands with flexible design configurations.

Benefits

- Enhances product quality by efficiently removing light impurities.

- Reduces production downtime with its modular, customizable configuration.

- Ensures food safety with a design that minimizes contamination risk.

- Lowers maintenance needs with easy-clean features and a sealed partition wall.

- Supports diverse grain processing requirements in a single solution.

- Applications

- Snacks, Grain, Chocolate, Dairy, Pulses, Paddy, Spices, Aqua feed, Biomass, Grain milling, Breakfast cereals, Cocoa, Animal feed, Pasta, Pet food, Nuts, Rice, Dried fruits, Baked goods, Oilseeds, Wheat, Confectionery, Coffee, Vegetables

- End products

- Baguettes, Energy bars, Spaghetti, Whole wheat flour, Wood pellets, Brown rice, Dried mango slices, Cattle feed, Basmati rice, Barley grains, Cocoa powder, Turmeric powder, Kibble, Dark chocolate bars, Split peas, Cornmeal, Fish pellets, Roasted coffee beans, Cornflakes, Roasted almonds, Cheese powder, Sunflower oil

- Steps before

- Dehulling, Grinding, Grain handling

- Steps after

- Sorting, Packing, Palletizing

- Input ingredients

- grain, granular products

- Output ingredients

- lighter particles, impurities, cleaned grain

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Modular design

- Individual cleaning solutions

- Air valve adjustability

- Fine-tunable

- Partition wall

- Sealed and moveable

- Air channel design

- Optimized for food safety

- Emptying function

- Residual emptying

- Particle separation

- High precision

- Machine use

- Stand-alone or combined

- Hygiene design

- Food-safe materials (FDA-approved)

- Modular Design

- Individual cleaning solutions

- Separation Mechanism

- Fine-tunable air valve

- Adjustability

- Multiple adjustment options

- Food Safety Design

- FDA-approved materials

- Partition Wall

- Sealed and moveable

- Emptying Function

- Residual emptying

- Air Channel

- Optimized for hygiene

- Operation Type

- Standalone or combination

- Air Recycling

- MVST integrated

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Modular design

- Modular design

- Enables individual cleaning solutions

- Discharge method

- Sealed and moveable partition wall

- Feed method

- Residual emptying function

- Control panel type

- Fine-tunable air valve

- Modular design

- Individual cleaning solutions

- Combination options

- Standalone or with Vitaris separator MTRD

- Air valve adjustment

- Fine-tunable air valve

- Separation precision

- High-precision removal with moveable partition wall

- Food-safe design

- FDA-approved materials

- Emptying function

- Residual emptying option

- Flexibility

- Use as standalone or combined with air-recycling aspirator MVST