Pick and place robotic system for confectionery decoration

For food producers seeking precision in snack decoration, this system enhances product appeal by expertly placing toppings like chocolates or nuts, ensuring consistent quality at high speeds.

Arranges and Sorts Toppings on Confectionery Products

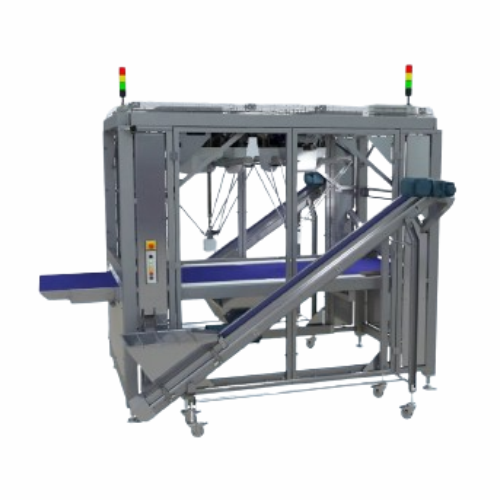

The DOS 0800 Flex Picker from Krüger & Salecker Maschinenbau GmbH & Co. KG is a robust pick and place robotic system designed to streamline the addition of toppings to food products in high-volume production environments. This fully automatic system leverages pneumatic vacuum grippers to accurately place items like almonds, chocolate beans, and freeze-dried fruits on solid and granule-based products such as fruit bars and protein bites. With a working width of 800 mm and capable of processing up to 500 pieces per minute, the DOS 0800 is ideal for medium to large-scale food and beverage operations, including confectionery, bakery, and snack manufacturing. Integration into existing production lines is seamless, allowing for flexible configurations with up to six pickers operating simultaneously. The system’s design ensures all-around viewing of the working area, facilitating easy monitoring and operation. Customization and integration support are available to tailor the system to specific production needs, ensuring optimal performance and efficiency.

Benefits

- Enhances product precision with accurate topping placement, reducing waste.

- Boosts production speed with capability to handle up to 500 pieces per minute.

- Facilitates integration into existing systems, minimizing setup costs.

- Allows flexible operation with configurable 1-6 picker setup.

- Provides easy monitoring with all-around viewing of the working area.

- Applications

- Cookies, Snacks, Chocolates, Fruit bars, Nuts, Sweets, Protein bites, Tarts

- End products

- Chocolate-topped protein bites, Sprinkle cookies, Nut-coated chocolates, Freeze-dried fruit snacks, Assorted dragee packages, Decorative tarts with wine gums, Whole almonds fruit bars

- Steps before

- Preparation of carrier goods, Smoothing surface for placement

- Steps after

- Integration into production chains, Packaging, Quality inspection

- Input ingredients

- whole almonds, chocolate beans, nuts, dragees, wine gums, freeze-dried fruits, chocolates, cookies, tarts

- Output ingredients

- fruit bar, protein bite, decorated goods

- Market info

- Krueger & Salecker is known for designing and manufacturing high-quality industrial equipment, particularly specialized machinery for the production of confectionery and bakery products, with a strong reputation for innovation and reliability in engineered-to-order solutions.

- Mode of Operation

- Fully automatic

- Production Capacity

- Medium and large

- Working Width

- 800 mm

- Dimensions (LxWxH)

- 3, 300 x 3, 000 x 2, 500 mm

- Integration

- Into existing production chains

- Output Speed

- Up to 500 pieces per minute

- Number of Pickers

- Flexible, 1-6 pickers possible

- Automation level

- Fully automatic

- Product integration capability

- Integration into existing production chains

- Production capacity

- Medium to large

- Picker flexibility

- 1-6 Flex Pickers

- Operating speed

- Up to 500 pieces per minute

- Surface smoothness requirement

- Required for placement

- Carrier material types

- Chocolates, cookies, tarts

- Compatible bulk goods

- Nuts, dragees, wine gums, freeze-dried fruits

- Pneumatic vacuum gripping suitability

- Various bulk types

- Suitable Surface

- Smooth

- Machine footprint

- 3, 300 x 3, 000 x 2, 500 mm (LxWxH)

- Working width

- 800 mm

- Picker configuration

- 1-6 pickers

- Surface requirement

- Smooth surface

- Integration possibilities

- Integration into existing production chains

- Picker Flexibility

- 1-6 flexible pickers

- View Accessibility

- View from all sides to the working area

- Expansion Capability

- Expandable to up to 6 Flex Pickers