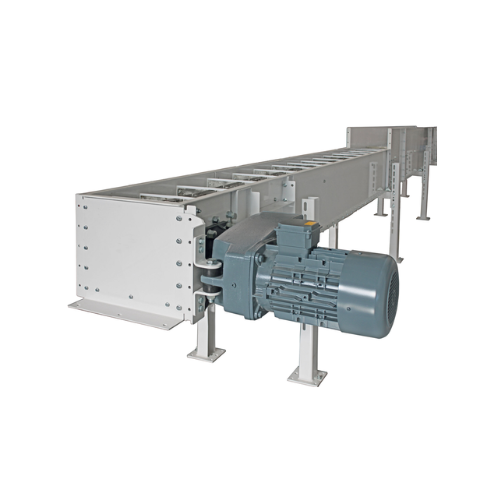

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed for gentle and sanitary transport of grains, powders, and more, while enhancing operational efficiency and reducing noise in continuous, high-speed processing operations.

Transports and Sorts Bulk Materials Efficiently

The Chain Conveyor LBCB from Bühler Group is engineered for exceptional bulk material transport, tailored specifically for grain processing companies, food manufacturers, and other industries demanding reliable material handling. This conveyor utilizes a modular design, allowing customization to meet various operational needs, from conveying grain to sorting confectionery. Equipped with plastic scrapers and rubber cleaning vanes, it ensures minimal product residue, achieving stringent sanitation standards essential in food and feed industries.

Capable of supporting continuous, high-speed operations, the LBCB efficiently handles powders and granules, proving its versatility across diverse sectors such as dairy, biomass, and advanced materials. Integration into existing production lines is seamless, with options for automation via PLC control and a zero-motion monitor that ensures operational reliability. Constructed from durable materials like superior-quality steel, it promises reduced maintenance and extended machine life, while its design features, such as a return rail, significantly decrease operational noise. Additionally, Bühler offers engineering support for custom configurations, making the LBCB a versatile and crucial component of any modern processing facility.

Benefits

- Enhances workflow efficiency with seamless integration into high-speed production lines.

- Minimizes contamination risk through advanced sanitation features, meeting stringent industry standards.

- Lowers maintenance costs with durable materials and self-cleaning components.

- Ensures reliable operation with built-in safety features like a zero-motion monitor.

- Reduces operational noise by up to 50%, enhancing workplace environment.

- Applications

- Dairy, Paints and coatings, Pulses and spices, Printing inks, Chemicals and cosmetics, Aqua feed, Biomass, Breakfast cereals, Batteries, Dried fruits and vegetables, Animal feed, Pasta, Nuts, Wheat and grain, Advanced materials, Electronic materials, Baked goods, Oilseeds, Insect technology, Coffee, Confectionery and snacks, Rice and paddy

- End products

- Energy bars, Pellets, Wood pellets, Nail varnish, Lithium-ion batteries, White rice, Thermal transfer ribbons, Acrylic paints, Bread flour, Insect protein powder, Roasted coffee beans, Penne pasta, Cornflakes, Lentil flour, Granola, Dried apricots, Almonds, Conductive inks, Sunflower oil, Sliced bread, Chocolate bars, Gouda cheese, Crumb feed

- Steps before

- Raw material handling, Milling, Grinding, Flaking, Dehulling, Drying

- Steps after

- Packing, Palletizing, Sifting, Grading, Sorting

- Input ingredients

- grainy products, floury products, grain, wheat, rice, coffee, brewing materials

- Output ingredients

- conveyed grain, conveyed flour, processed coffee, processed brewing materials

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Customization

- Bottom-up approach

- Sanitation Features

- Plastic scrapers, rubber cleaning vanes

- Safety Devices

- Overflow device, zero-motion monitor

- Versatility

- Modular, customizable configurations

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Zero-motion monitoring

- Speed detection

- Overflow protection

- Overflow Flap

- Sanitation improvement

- Plastic scrapers and cleaning vanes

- Versatility

- Modular configuration

- Noise reduction

- Up to 50%

- Customization level

- Flexible according to customer specifications

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Trough size

- Customizable

- Chain type

- Multiple options available

- Footprint

- Compact

- Modularity

- High, with standardized components

- Discharge method

- Customizable according to specifications

- Cleaning access

- Outlet flaps under the trough

- Noise reduction

- Up to 50% reduction

- Scraper type

- Plastic with rubber cleaning vanes

- Material of construction

- Superior-quality steel

- Design

- Hygienic with dirt grooves on chain wheels

- Chain and Bearing Options

- Multiple configurations available

- System Modularity

- Modular and standardized components

- Customized Design

- Configured according to customer specifications

- Flexible Configuration

- Adaptable to various applications