Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tray movement for precise filling of diverse food products, all while effortlessly adjusting to varying production speeds and tray sizes.

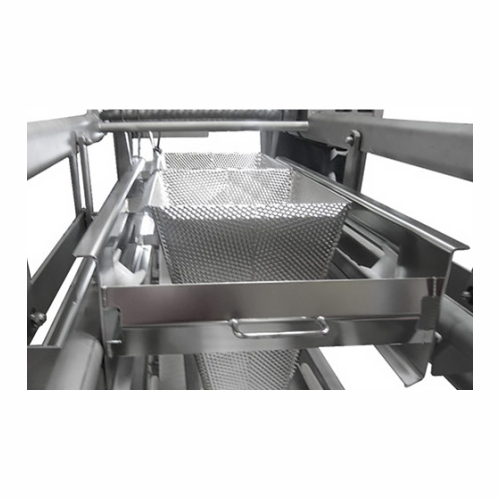

Precisely Transfers and Fills Food Products

The Dual Axis Funnel Follower is an innovative solution from Heat and Control, engineered to augment the precision and efficiency of your food packaging line. This system is designed to seamlessly transfer weighed portions of diverse food products into trays, bowls, or cartons, minimizing waste and enhancing productivity. The device integrates with existing conveyors to mimic their motion, allowing for precise filling and eliminating spills with its No Tray-No Fill operation. Suitable for dry, fresh, and frozen foods across industries such as confectionery, meat, and prepared foods, the Dual Axis Funnel Follower adapts easily to varying speeds and container sizes. It operates in continuous, automated processes and supports diverse product types, including solids, powders, and granules. Built to meet AMI sanitary requirements, the system combines robust performance with hygienic operation, offering optional customization to meet specific industry standards.

Benefits

- Enhances filling precision for reduced product waste and improved efficiency.

- Adapts seamlessly to different tray sizes and speeds, ensuring versatile application.

- Minimizes cleanup time and spills with No Tray-No Fill operation.

- Meets AMI sanitary standards, maintaining high hygiene levels.

- Integrates easily into existing production lines, optimizing workflow without extensive modifications.

- Applications

- Seafood, Salad, Candy, Pasta, Fresh food products, Confectionery, Meat, Cheese, Frozen food products, Nuts, Vegetables, Poultry, Prepared foods, Dry food products, Fruit

- End products

- Chocolate truffles, Granola bars, Roasted almonds, Pre-packaged salads, Trail mix, Chicken pot pies, Assorted gummy candies, Pre-cut fruit salads, Shredded mozzarella cheese, Pre-packaged stir fry vegetables, Canned tuna, Rigatoni pasta, Frozen chicken nuggets

- Steps before

- Weighing, Conveying, Inspection

- Steps after

- Packing, Product Transfer

- Input ingredients

- weighed portions, dry food products, fresh food products, frozen food products

- Output ingredients

- trays, bowls, cartons

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Filling speed

- Adjustable for different speeds

- Automation

- No Tray-No Fill operation

- Conveyor Options

- Single and double lane

- Sanitary Requirements

- AMI sanitary requirements

- Filling Efficiency

- To maximize fill time

- Tray Size Adjustment

- Easily adjustable

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Adjustable for different speeds and tray sizes

- Cleaning method

- Easy adjustability for optimal cleaning

- Energy efficiency

- Optimized for minimal energy use

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design for limited space installations

- Feed/discharge method

- No Tray-No Fill operation

- Lanes

- Single and double lane conveyor options

- Tray size adjustability

- Easily adjustable for different tray sizes

- Funnel motion

- Precise motion to follow each container

- Lane configuration

- Single and double lane

- Speed adjustment

- Easily adjustable for different speeds

- Tray size compatibility

- Adjustable for different tray sizes

- Centerline adjustment

- Adjustable for different centerlines

- No Tray-No Fill operation

- Included