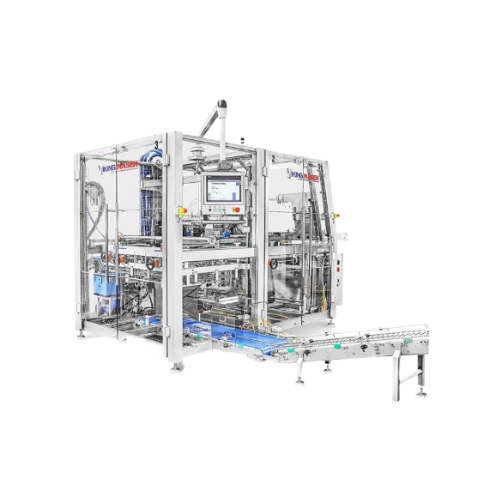

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that enhances efficiency by effortlessly managing diverse tray shapes and ensuring seamless integration into your production line.

Forms and Erects Packaging Trays

The CFM-T Tray Erector from Viking Masek is a robust and versatile packaging solution, ideal for manufacturers looking to efficiently handle a wide variety of products from candy to medical supplies. This machine excels in forming and erecting trays using a single-head operation, ensuring continuous and high-speed production with speeds up to 25 trays per minute. It features a controlled carton supply system coupled with hot melt application for secure tray assembly. The CFM-T is equipped with servo drives for precise operation and an intuitive touch screen HMI for seamless control and easy format change-overs. Its rugged stainless steel construction ensures long-term durability and corrosion resistance, while safety guarding and optional remote control enhance operational safety and flexibility. This machine supports various tray sizes and styles, integrating smoothly into existing workflows. Viking Masek offers customization options such as adjustable forming heads and extended carton magazines, alongside comprehensive engineering support, making the CFM-T Tray Erector a versatile addition to any packaging line.

Benefits

- Enhances production efficiency by maintaining a high throughput of up to 25 trays per minute.

- Minimizes downtime with quick format change-overs facilitated by intuitive HMI controls.

- Promotes energy efficiency and precision with integrated servo drives.

- Ensures product versatility with support for multiple tray sizes and configurations.

- Increases operational safety with robust stainless steel construction and comprehensive safety guarding.

- Applications

- Medical devices, Snacks, Bakery, Cheese, Fish, Liquids, Fresh fruit, Beans, Supplies, Cannabis, Candy, Pasta, Pet food, Nuts, Rice, Cereal, Meat, Coffee, Vegetables, Poultry, Powders

- End products

- Dog biscuits, Spaghetti, Potato chips, Basmati rice, Fruit juice, Chicken nuggets, Kidney beans, Granola bars, Protein powder, Coffee beans, Cheddar cheese, Bread rolls, Syringes, Smoked salmon, Surgical gloves, Almonds, Carrots, Apples, Cbd oil, Chocolate bars

- Steps before

- Tray Design and Planning, Material Selection and Preparation, Carton Supply Arrangement

- Steps after

- Carton Packing, Sealing, Distribution Packaging

- Input ingredients

- carton blanks, tray blanks

- Output ingredients

- erected trays, erected cases

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 25 cpm

- Bag Size Min

- 200 x 150 x 35 mm

- Bag Size Max

- 400 x 600 x 350 mm

- Configuration

- Singlehead

- Power Supply

- 9 kVA

- Weight

- 900 kg

- Construction Material

- Rugged stainless steel

- Controls

- Siemens or Allen Bradley

- Human Interface

- Intuitive touch screen (HMI)

- Carton Supply

- Controlled

- Drive Type

- Servo

- Vacuum System

- Vacuum pump included

- Working mechanism

- Tray erecting

- Automation level

- PLC-controlled

- Changeover time

- Easy format change-over

- Batch vs. continuous operation

- Continuous

- Safety features

- Safety guarding

- Control interface

- Intuitive touch screen HMI

- Tray forming capability

- Multiple tray shapes

- Speed

- Max 25 cpm

- Abrasion resistance

- Standard

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- High resistance

- Density/particle size

- Compatible with various sizes

- Construction Material

- Rugged stainless steel

- Tray Size Range

- Min 200 x 150 x 35 mm / Max 400 x 600 x 350 mm

- Configuration

- Singlehead

- Weight

- 900kg

- Outfeed Conveyor Styles

- Various styles

- Forming Head

- Adjustable

- Frame Sizes

- Different sizes available

- Control Panel Type

- Intuitive touch screen human interface (HMI)

- Control panel type

- Intuitive touch screen human interface (HMI)

- Integration possibilities

- Siemens or Allen Bradley controls

- Frame size options

- Different frame sizes to accommodate large carton range

- Outfeed conveyor styles

- Various styles

- Remote control

- Remote control option available

- Carton magazine

- Extended carton magazine option