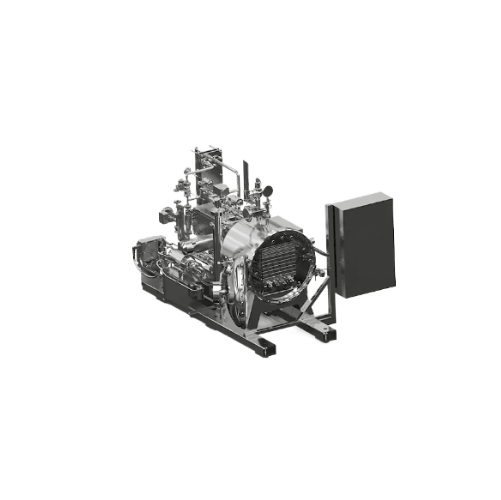

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agitation system, designed to optimize heating and cooling in retort packages through precise, recipe-driven linear motion.

Enhances Heating and Cooling with Precise Agitation

The Efficient Agitation System by JBT optimizes your batch retort processing through recipe-driven, linear agitation. Utilizing a hydraulic platform, it provides tailored motion profiles to match the thermal needs of diverse products. Ideal for applications in the food and pet food industries, it’s frequently used for products like infant cereal, Greek yogurt, and canned tuna. This system can significantly reduce process times by up to 40%, improving throughput and product quality. Integration is seamless, with PLC-controlled automation allowing for precise adjustments during processing. Designed for versatility, it offers higher accelerations for viscous materials and gentle handling for delicate items, maintaining product integrity. Constructed with robust materials, it ensures durability and compliance with industry standards. Custom engineering support is available for specific production requirements.

Benefits

- Accelerates processing by reducing heating and cooling times by up to 40%, boosting throughput.

- Enhances product quality by minimizing burn-on and clumping through precise agitation.

- Allows flexible production with customizable motion profiles to handle a range of product viscosities and packaging needs.

- Decreases energy use with tailored acceleration profiles, optimizing resource efficiency.

- Supports compliance with industry standards, ensuring safe and reliable operation.

- Applications

- Soups, Sauces, Pet food, Dairy alternatives, Fruits, Oils, Tuna processing, Nuts, Dressings, Seasonings, Baby food, Dairy

- End products

- Olive oil, Infant cereal, Tomato soup, Roasted almonds, Canned peaches, Almond milk, Kibble, Greek yogurt, Barbecue seasoning, Canned tuna, Marinara sauce, Ranch dressing

- Steps before

- Preparation, Filling

- Steps after

- Sterilization, Packing, Cooling

- Input ingredients

- retortable rigid packages, flexible packages, baby food, dairy products, dairy alternatives, fruits, nuts, oils, soups, sauces, seasonings, dressings, pet food, viscous products, delicate products

- Output ingredients

- agitated and thermally processed products, reduced clumping products, reduced burn-on products, faster heated products, faster cooled products

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Motion Profile Control

- Hydraulic platform

- Acceleration Control

- Independent of stroke frequency

- Stroke Frequency

- Adjustable

- Process Time Reduction

- Up to 40%

- Recipe-driven Motion

- Yes

- Product Agitation

- Linear

- Working mechanism

- Hydraulic platform with flexible motion profiles

- Integrated steps

- Recipe-driven linear motion within retort

- Batch vs continuous operation

- Batch

- Motion profile customization

- Tailored to product thermal requirements

- Agitation control

- Linear agitation for faster heating and cooling

- Stroke frequency

- Independent adjustment for product needs

- Automation level

- Recipe-driven automation

- Changeover time

- Adaptation of motion profiles during process

- Cleaning method

- CIP compatible

- Motion profile system

- Flexible

- Hydraulic platform

- Yes

- Motion profile adjustment

- Recipe-driven

- Acceleration setting

- Independent of stroke frequency

- Stroke frequency setting

- Variable

- Product specific tailoring

- Yes